Polycrystalline superhard material with gradient nano-micro structure and synthesis method thereof

A technology of polycrystalline superhard and nano-materials, applied in polycrystalline material growth, chemical instruments and methods, single crystal growth, etc., to achieve the effects of good wear resistance, compact structure, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

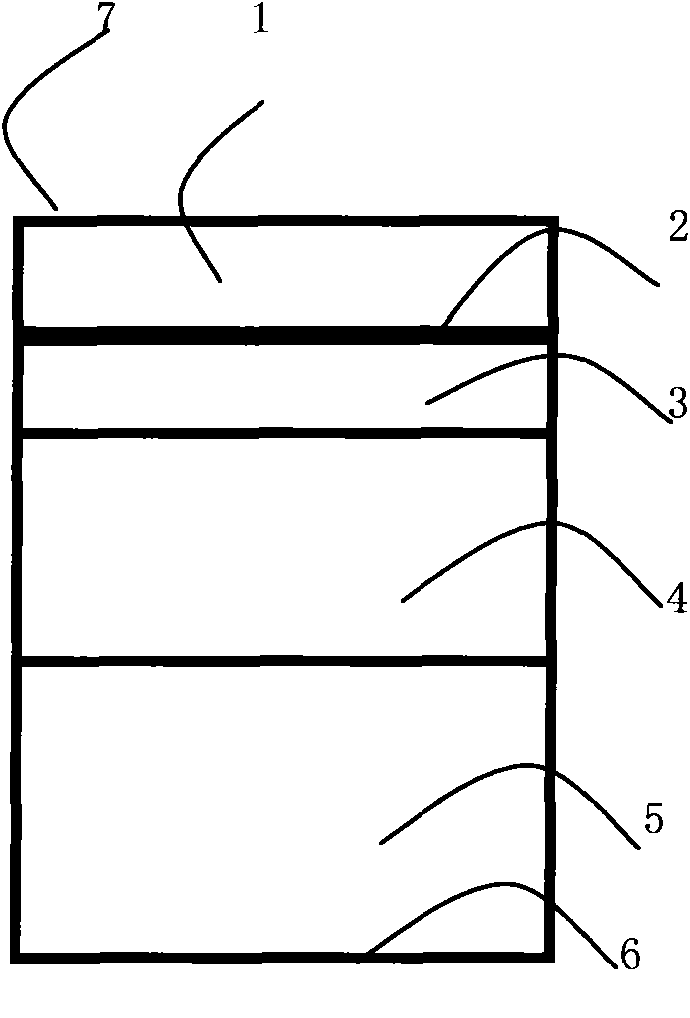

[0043] Tool material grown for turning tools: see figure 1 .

[0044] Table 1: An example of the proportion of tool material components used for growing turning tools

[0045]

[0046] Prepare the nanomaterial precursor according to Table 1, add ethanol and wet ball mill for 4 hours, then take it out and dry it, send it to a vacuum treatment system (not marked), 750K hydrogen, purify for 30 minutes, and pass nitrogen after cooling, please refer to figure 1 In situ assembly. Under the conditions of pressure 8GPa and temperature 1600-2200K, the process is grown for 120 seconds, then cooled and the pressure is released to obtain a gradient nano-microstructure polycrystal with a diameter of 14 mm and a height of 5 mm.

Embodiment 2

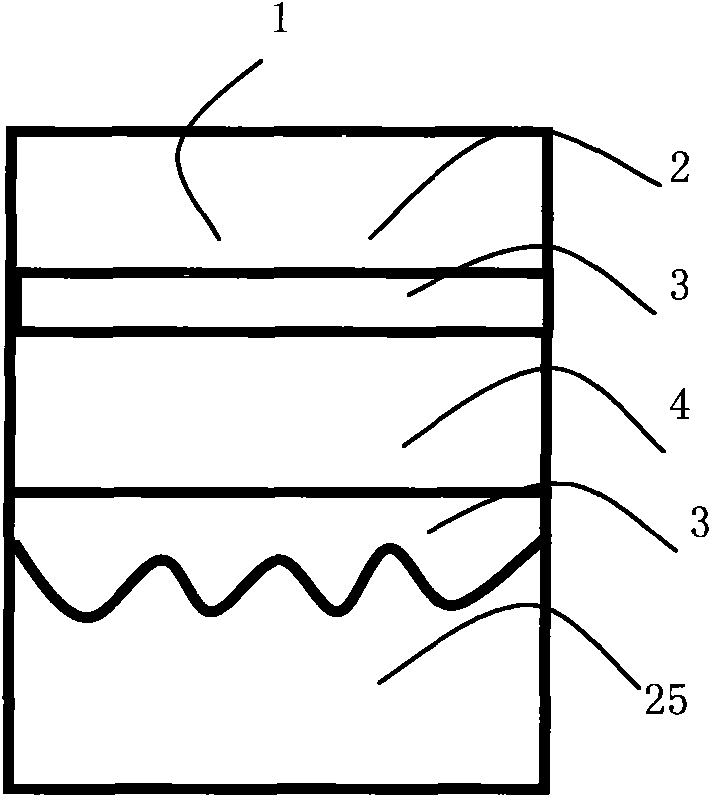

[0048] Cutting material grown for drill bits: see figure 2 .

[0049] Table 2: Examples of component distribution ratios of growing drill bit cutting materials

[0050]

[0051] Prepare the nanomaterial precursor according to Table 2, add ethanol and wet ball mill for 6 hours, then take it out and dry it, send it to a vacuum treatment system (not marked), 780K hydrogen, purify for 40 minutes, and pass nitrogen after cooling, please refer to figure 2 In situ assembly. Under the conditions of pressure 8GPa and temperature 1600-2200K, the process is grown for 150 seconds, then cooled, and the pressure is released to obtain a gradient nano-microstructure polycrystal with a diameter of 14 mm and a height of 8 mm.

Embodiment 3

[0053] Ball head material grown for durometer indenters: see figure 1 .

[0054] Table 3: An example of the distribution ratio of the ball head material used as a hardness tester indenter

[0055]

[0056] Prepare the nanomaterial precursor according to Table 3, add ethanol and wet ball mill for 6 hours, then take it out and dry it, send it to a vacuum treatment system (not marked), 760K hydrogen, purify for 30 minutes, and pass nitrogen after cooling, please refer to figure 1 In situ assembly. Under the conditions of pressure 8GPa and temperature 1600-2200K, grow for 25 seconds, then cool and release the pressure to obtain a gradient nano-microstructure polycrystal with a diameter of 4 mm and a height of 5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com