Polycrystalline superhard material with gradient nano-micro structure and synthesis method thereof

A technology for polycrystalline superhard and nano-carbon materials, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and single crystal growth to achieve the effects of high overall strength, good wear resistance and reduction of internal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

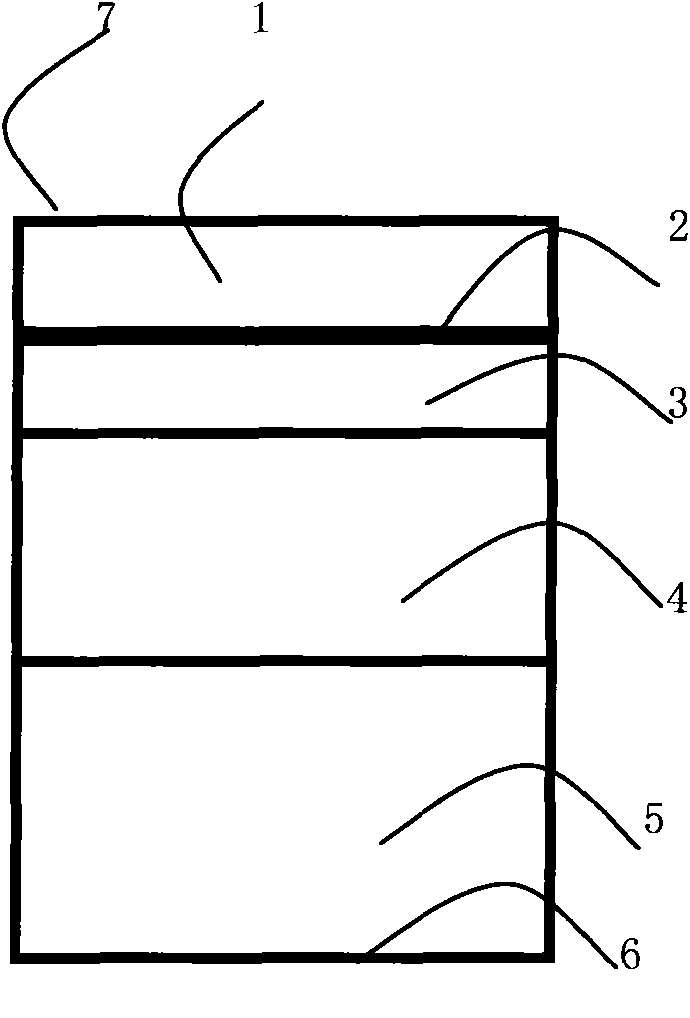

[0043] Tool material grown for turning tools: see figure 1 .

[0044] Table 1: An example of the proportion of tool material components used for growing turning tools

[0045]

[0046] Prepare the nanomaterial precursor according to Table 1, add ethanol and wet ball mill for 4 hours, then take it out and dry it, send it to a vacuum treatment system (not marked), 750K hydrogen, purify for 30 minutes, and pass nitrogen after cooling, please refer to figure 1 In situ assembly. Under the conditions of pressure 8GPa and temperature 1600-2200K, the process is grown for 120 seconds, then cooled and the pressure is released to obtain a gradient nano-microstructure polycrystal with a diameter of 14 mm and a height of 5 mm.

Embodiment 2

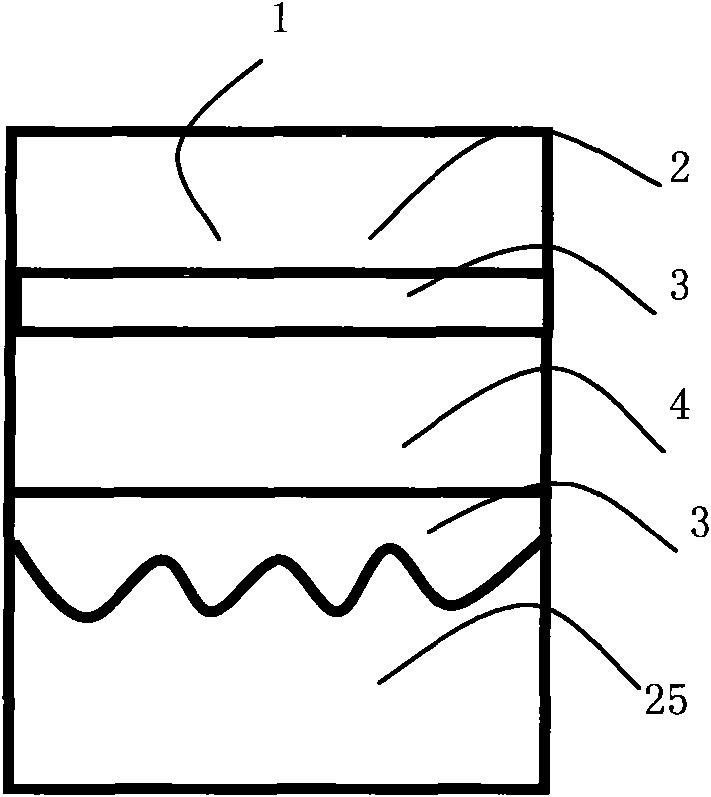

[0048] Cutting material grown for drill bits: see figure 2 .

[0049] Table 2: Examples of component distribution ratios of growing drill bit cutting materials

[0050]

[0051] Prepare the nanomaterial precursor according to Table 2, add ethanol and wet ball mill for 6 hours, then take it out and dry it, send it to a vacuum treatment system (not marked), 780K hydrogen, purify for 40 minutes, and pass nitrogen after cooling, please refer to figure 2 In situ assembly. Under the conditions of pressure 8GPa and temperature 1600-2200K, the process is grown for 150 seconds, then cooled, and the pressure is released to obtain a gradient nano-microstructure polycrystal with a diameter of 14 mm and a height of 8 mm.

Embodiment 3

[0053] Ball head material grown for durometer indenters: see figure 1 .

[0054] Table 3: An example of the distribution ratio of the ball head material used as a hardness tester indenter

[0055]

[0056] Prepare the nanomaterial precursor according to Table 3, add ethanol and wet ball mill for 6 hours, then take it out and dry it, send it to a vacuum treatment system (not marked), 760K hydrogen, purify for 30 minutes, and pass nitrogen after cooling, please refer to figure 1 In situ assembly. Under the conditions of pressure 8GPa and temperature 1600-2200K, grow for 25 seconds, then cool and release the pressure to obtain a gradient nano-microstructure polycrystal with a diameter of 4 mm and a height of 5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com