Waterproof roll with plant root impaling resistance and manufacturing method thereof

A technology of waterproof coiled material and production method, which is applied to chemical instruments and methods, building structures, roofs using flexible materials, etc., can solve problems such as waterproof leakage, poor adaptability, roof leakage, etc., and achieve enhanced waterproofing mildew performance, reduce production costs, and prevent puncture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

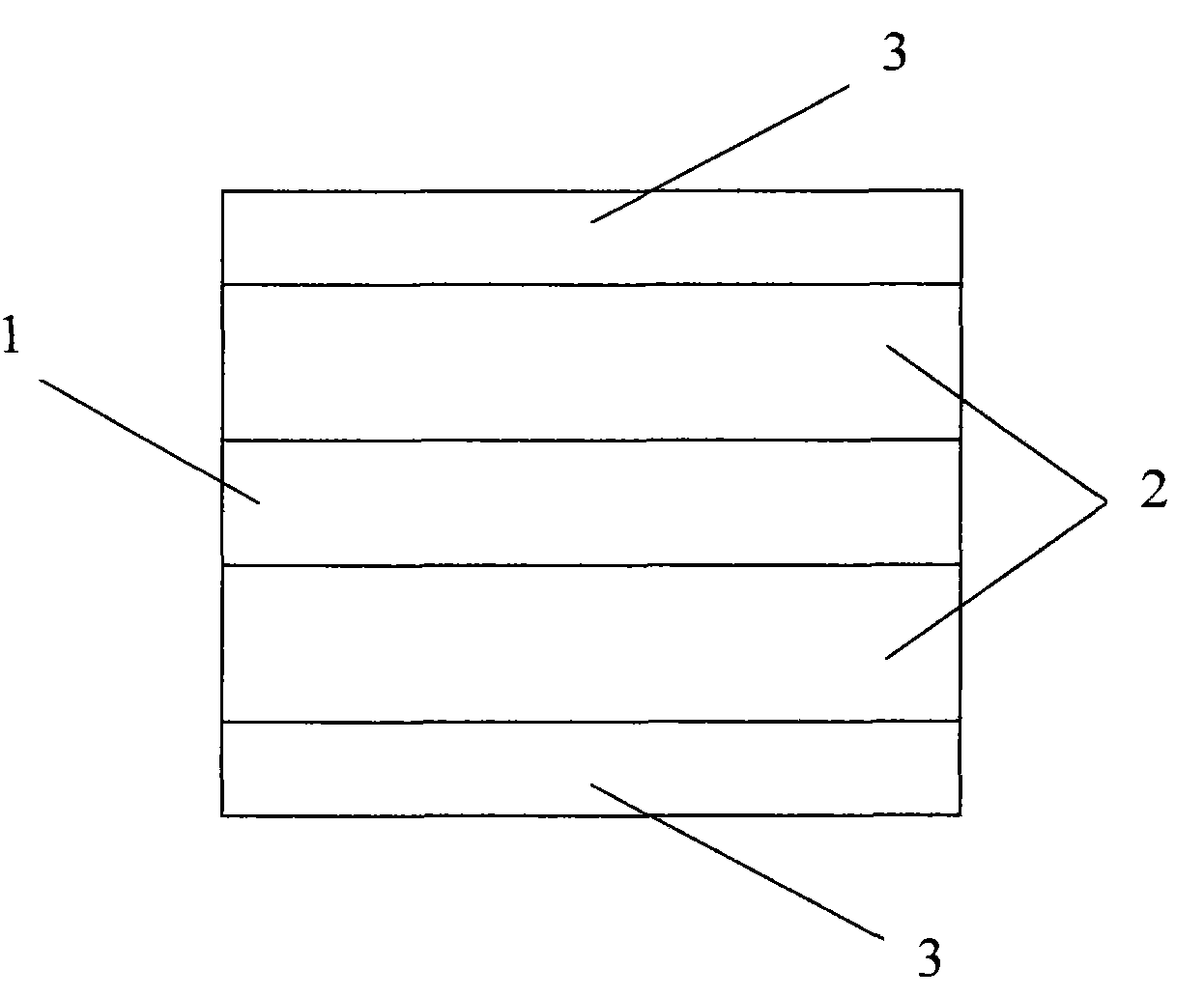

[0031] like figure 1 As shown, the anti-plant root puncture waterproof roll material of the present invention comprises a base layer 1, the upper and lower surfaces of the base layer 1 are modified asphalt chemical root-blocking agent waterproof layers 2, and the modified asphalt chemical root-blocking agent waterproof layer 2 The outer surface away from the base layer is the isolation layer 3 . The thickness of the base layer 1 is 1.0mm-1.2mm, the thickness of the modified asphalt chemical root-blocking agent waterproof layer 2 is 1.2mm-1.5mm, and the thickness of the isolation layer 3 is 0.2-0.4mm. The modified asphalt chemical anti-root agent waterproof layer 2 is a structure obtained by blending asphalt with chemical anti-root agent, resin, filler and auxiliary agent at 195°C by mechanical stirring. In this embodiment, the chemical root inhibitor is copper oxide powder, the resin and filler include SBS, APP, APAO, SBR; the auxiliary agent includes anti-aging agent and pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com