Method for replacing shield cutter in sand-pebble layer

A shield cutting tool and cutting tool replacement technology, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve problems such as subsidence, soil cutting, crushing obstruction, and impact on mechanical equipment, so as to achieve self-reliance and reduce soil adhesion. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

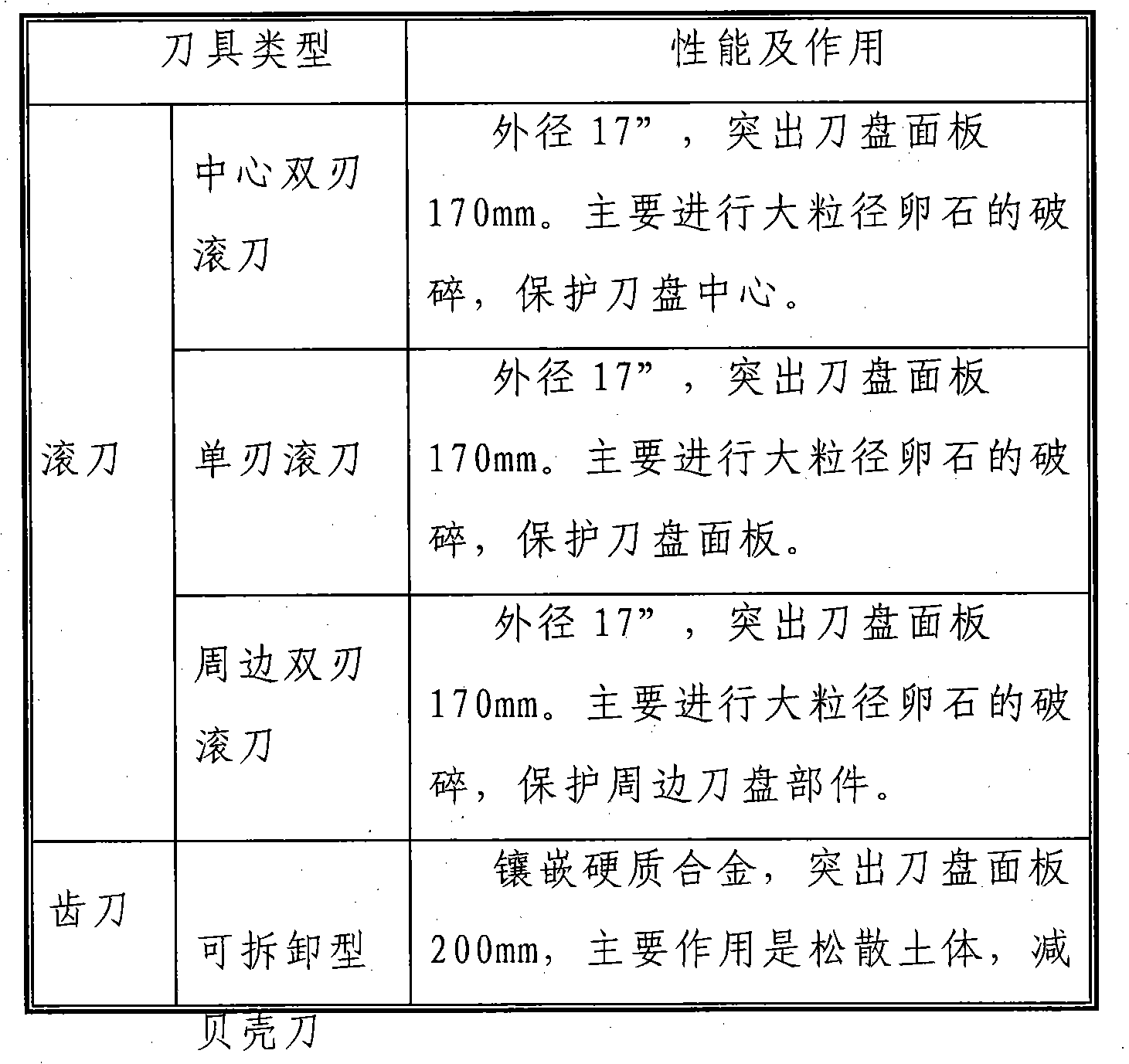

[0025] Further details will be given below in conjunction with specific engineering examples on which the present invention is based.

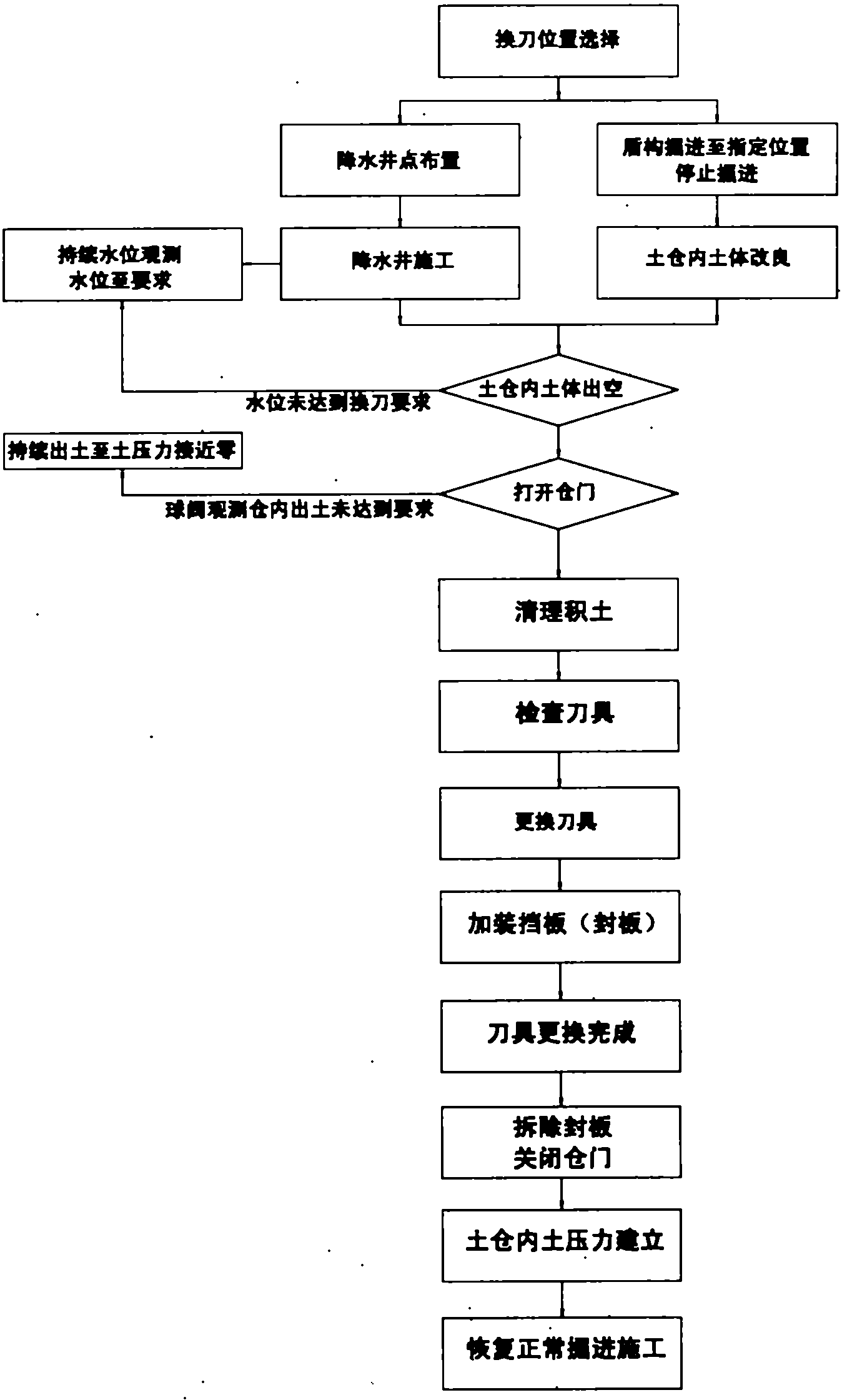

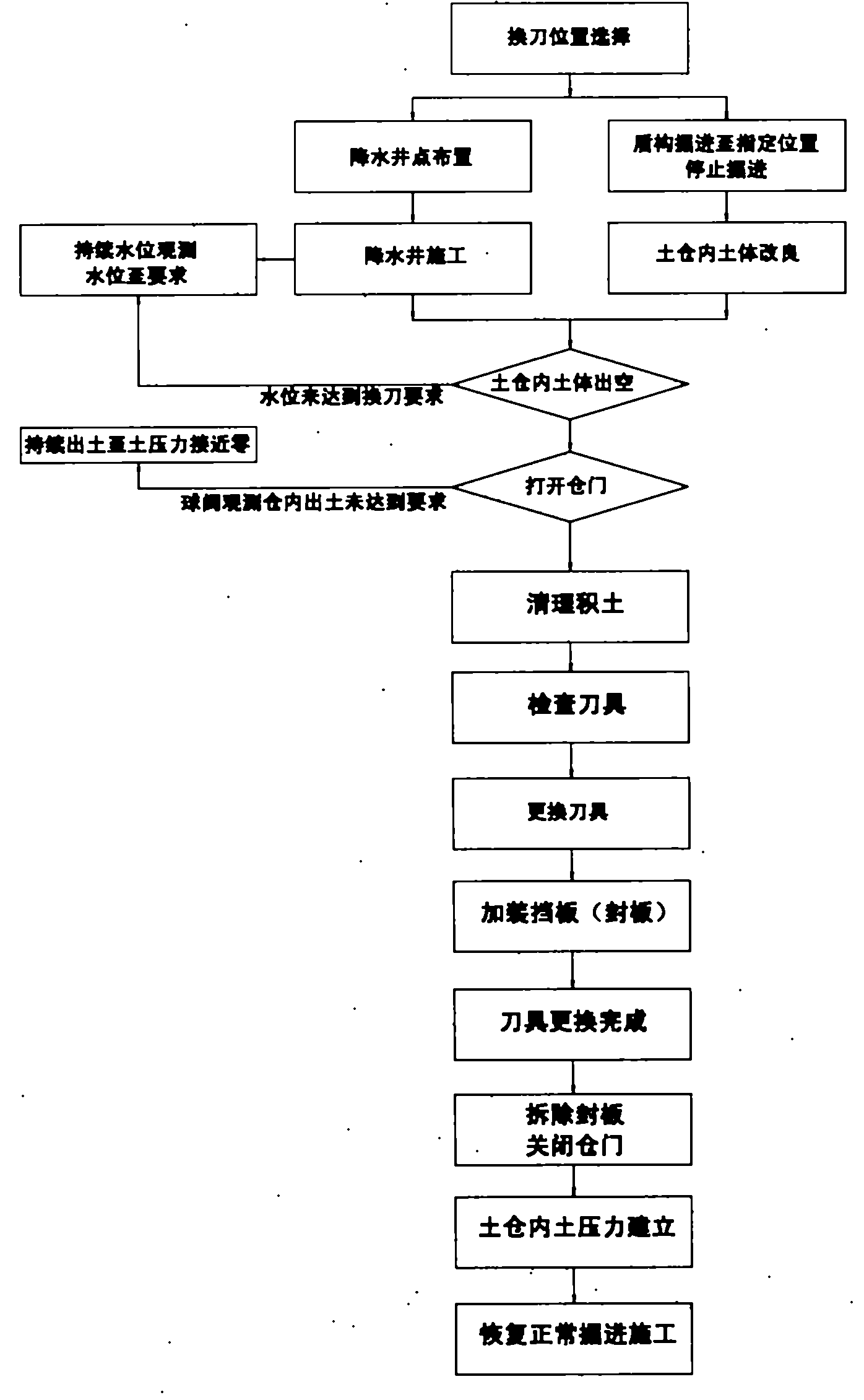

[0026] refer to figure 1 Shown, method of the present invention mainly comprises the following steps:

[0027] a. Preparation steps before tool replacement, including:

[0028] (1). Select the tool change position;

[0029] Before the tool change, the position of the tool change must be systematically considered. The selection of the tool replacement position is mainly based on the following principles:

[0030] a. The material and performance parameters of the tool determine the service life of the tool, which is converted into the corresponding tunneling mileage according to the service life of the tool;

[0031] b. Fully consider the feasibility and convenience of the implementation of ground reinforcement (precipitation construction) measures;

[0032] c. Avoid areas with complex surrounding environments, such as areas with many build...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com