System and method for proportional plus integral control in air separation energy saving process

A proportional-integral control and air separation technology, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as poor robustness, low precision, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

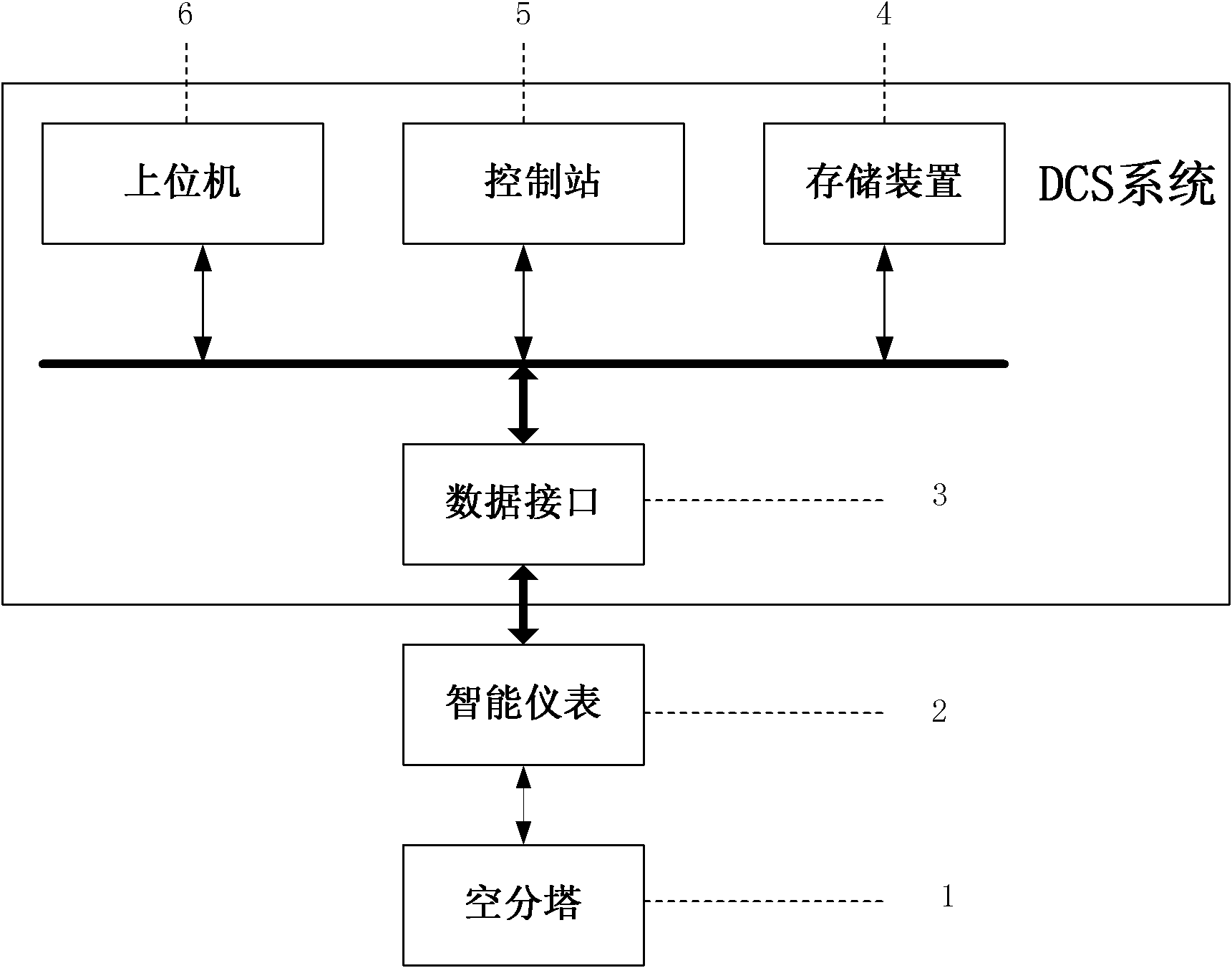

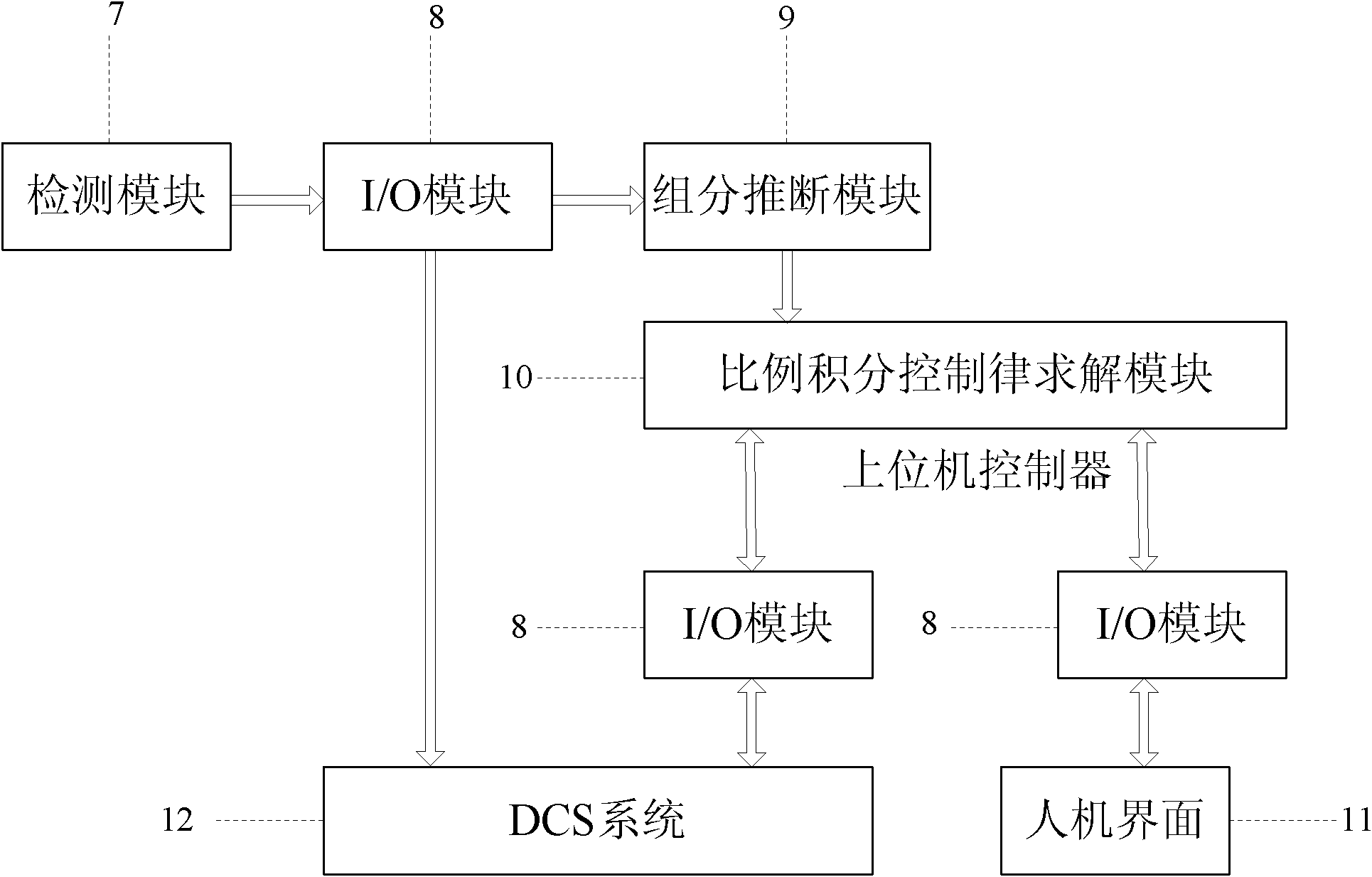

[0034] refer to figure 1 with figure 2 , a proportional-integral control system for an air separation energy-saving process, comprising an on-site intelligent instrument 2 and a DCS system 12 directly connected to an air separation tower 1, and the DCS system 12 includes a storage device 4, a control station 5 and a host computer 6, so The on-site intelligent instrument 2 is connected with the storage device 4, the control station 5, and the host computer 6 in turn through the field bus and the data interface 3; Temperature, pressure data, described data interface is in order to realize the function of I / O module 8 namely the input and output of data, host computer 6 comprises the proportional-integral controller in order to solve proportional-integral control law and output control variable change value, so The proportional-integral controller described above includes a component estimation module 9 and a proportional-integral control law solution module 10 .

[0035] Desc...

Embodiment 2

[0045] refer to figure 1 with figure 2 , a proportional-integral control method of an air separation energy-saving process, said control method comprising the following steps:

[0046] 1) Determine the sampling period t, and the t value, the relative volatility of nitrogen and oxygen relative to argon α N 、α O , the Antony constant a N , b N 、c N 、a O , b O 、c O stored in the historical database;

[0047] 2) Set the control law parameter k 11 , k 12 , k 21 , k 22 and the set value of liquid nitrogen concentration at the top of the upper tower X 1, 1 * , the set value of the concentration of liquid oxygen at the bottom of the tower X 3,n * ;

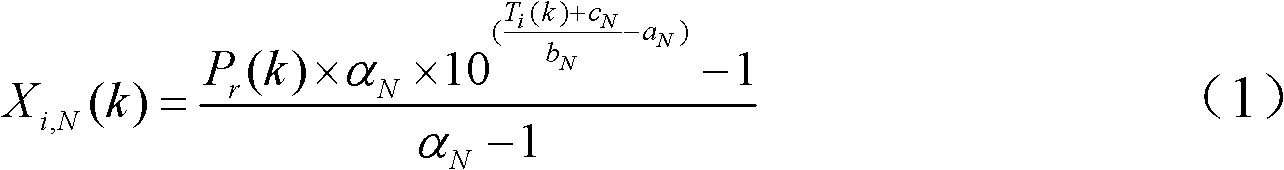

[0048] 3) Detect the pressure P in the rectification section at time k r (k), each tray temperature T i (k), calculate the component concentration value of liquid nitrogen and liquid oxygen, adopt formula (1) (2) to obtain:

[0049] X i , N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com