Multi-unit double-layer integrated evaporator of ice cream maker

An ice cream machine, an integrated technology, applied in the direction of evaporator/condenser, refrigerator, frozen dessert, etc., can solve the problems of increased manufacturing cost, difficult maintenance, complex evaporator structure, etc., to improve refrigeration efficiency and avoid mutual Blow-by, improve the effect of frost scraping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

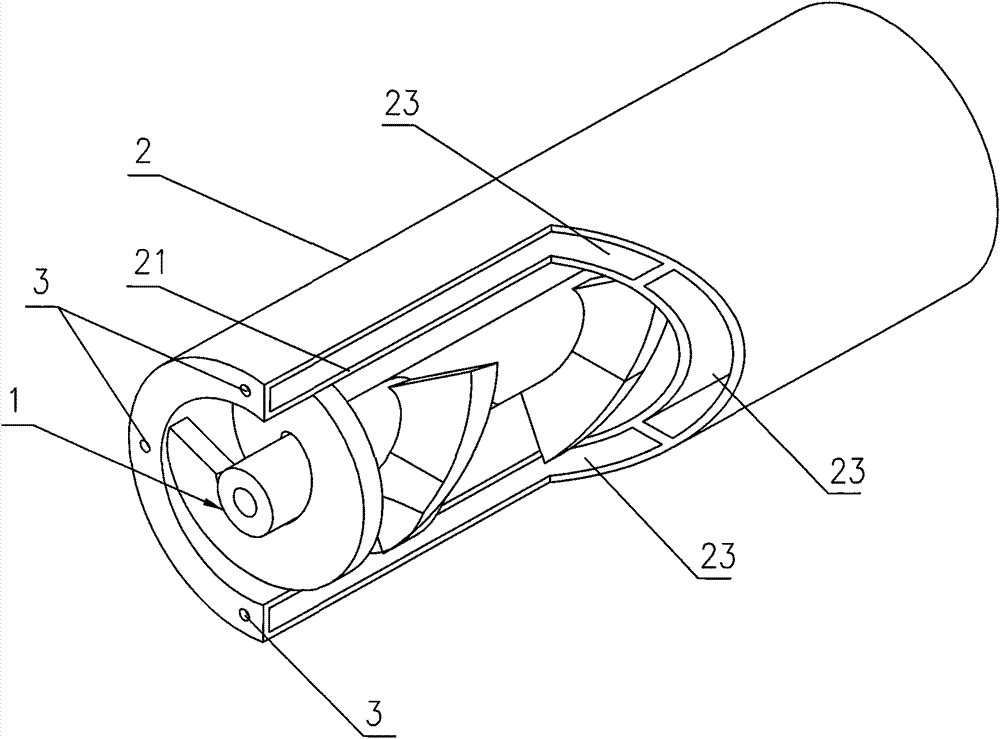

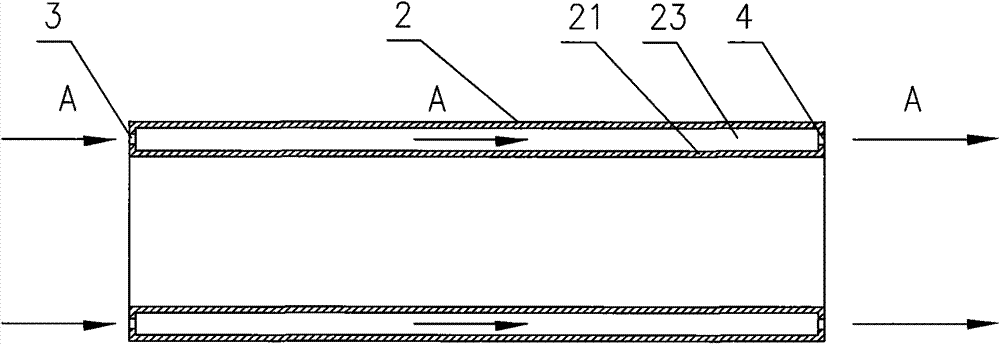

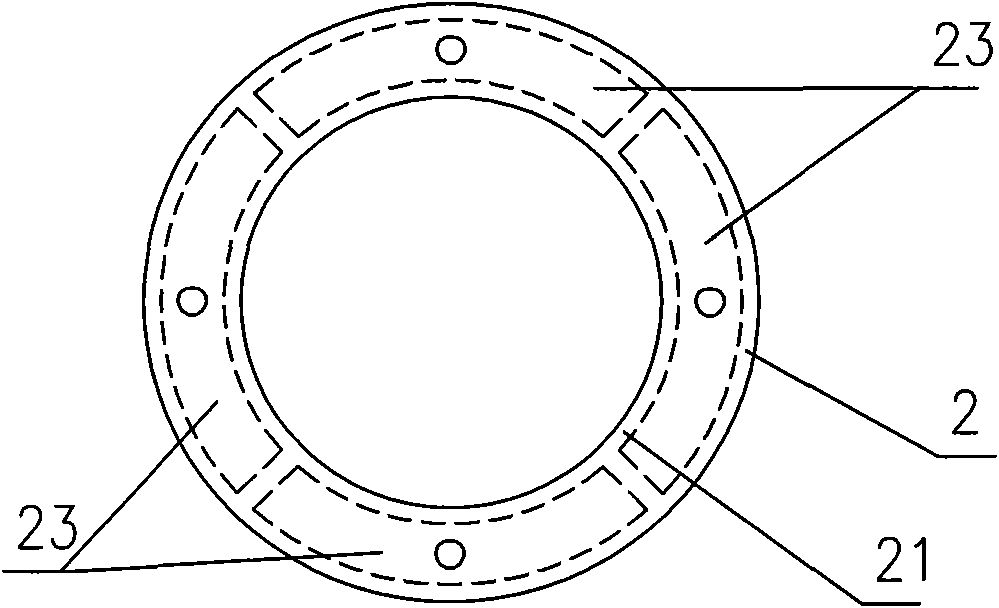

[0023] Such as Figure 1~3 As shown, it is a multi-unit double-layer integrated ice cream machine evaporator according to the present invention, which includes an outer sleeve 2 and an inner sleeve 21 for installing the agitator 1, the outer sleeve 2 is set on the inner sleeve 21, and the outer sleeve 2 and the inner tube 21 are integrally made, and the two are integrated at the end face, a cavity is formed between the outer sleeve 2 and the inner tube 21, and the end faces of the outer sleeve 2 and the inner tube 21 are respectively opened with The refrigerant inlet 3 and the refrigerant outlet 4 communicated in the cavity. In this embodiment, the cavity is evenly divided into four evaporating chambers 23 that are not connected and have the same size along the radial direction of the cavity. Extending axially, there are four pairs of refrigerant inlets 3 and refrigerant outlets 4. Each pair of refrigerant inlets 3 and refrigerant outlets 4 communicates with the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com