Diamond wire saw and manufacturing method thereof

A diamond wire saw and diamond technology, applied in the field of diamond tools and their preparation, can solve problems such as unusability and stiffness, and achieve the effects of overcoming easy wear, low production cost and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

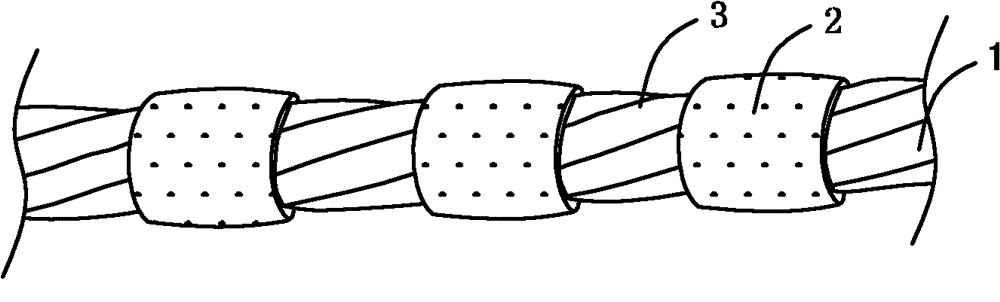

[0061] like figure 1 As shown in , a bending-resistant multi-strand steel wire rope 1 with a diameter of φ1 mm is degreased with acetone, and the high-temperature-resistant inorganic adhesive is applied to the steel wire rope at certain intervals. After drying and curing, an isolation masking area 2 is formed.

[0062] Take the metal brazing material, add organic glue and make a paste.

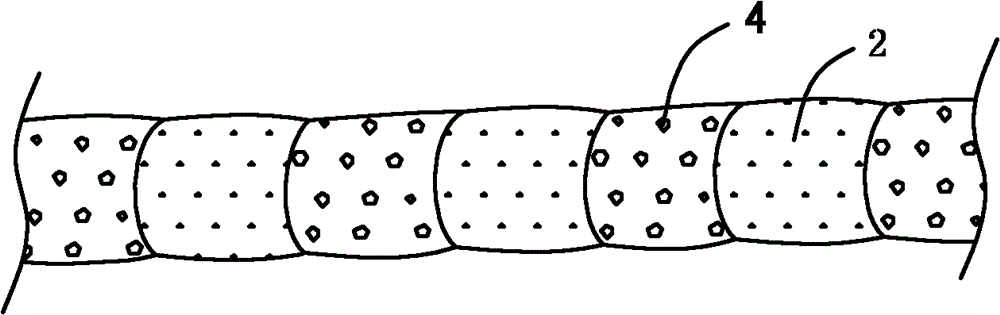

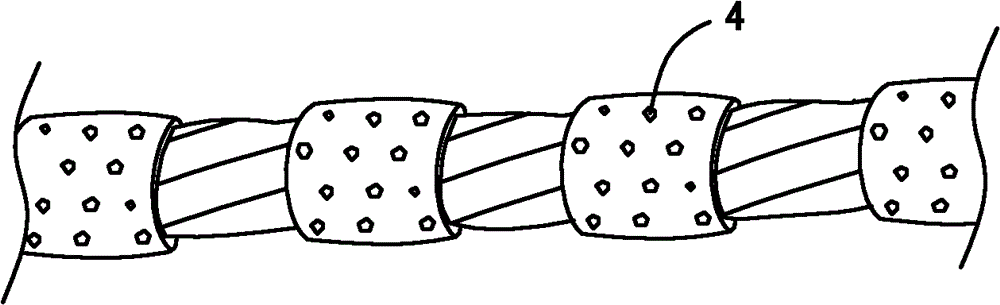

[0063] like figure 2 As shown in , use paste metal brazing material to smear the spaced part 3 on the multi-strand steel wire rope 1, then sprinkle diamond particles 4, spray a layer of paste metal brazing material after solidification, and then sprinkle diamond particles 4. Spray a layer of paste metal brazing material after solidification, put it into a vacuum brazing sintering furnace after drying, raise the temperature to 950°C, then cool it and take it out to obtain a semi-finished diamond wire saw. like image 3 and Figure 4 As shown in , the semi-finished wire saw is sandblasted t...

Embodiment 2

[0066] like Figure 6 As shown in , take a single thin steel wire 6 with a diameter of φ0.8mm, dip it in high temperature resistant inorganic glue and take it out. The release layer 7.

[0067] Take diamond abrasive grains and metal brazing material, add organic glue and make paste.

[0068] like Figure 7 As shown in , the release layer 7 is coated or cold-pressed with a diamond-containing paste 8 at intervals, and then the single-strand steel wire 6 coated with the paste 8 is put into a vacuum brazing furnace for sintering. After drying, place it in a vacuum brazing furnace and heat it up to 950°C before sintering. After cooling, exit the single-strand steel wire at the center to obtain a self-supporting (that is, without a metal matrix) ring-shaped diamond brazing layer (paste 8 obtained after sintering), that is, as Figure 8 The diamond bead 40 shown in. Then these beads 40 are strung on the φ1mm bending-resistant multi-strand steel wire rope 1 at intervals, and fixe...

Embodiment 3

[0071] Take diamond abrasive grains and metal brazing material, add organic glue and make paste.

[0072] Take a steel pipe with a diameter of 0.5 mm to 2 mm, coat or cold press the paste on it, and then put it into a vacuum brazing furnace for sintering. After being released from the furnace, the above-mentioned steel pipe is cut into small sections with a length of 5-10 mm to obtain a diamond bead with a metal matrix 9, such as Figure 9 shown in . Then these beads 40 are strung on the φ1mm bending-resistant multi-strand steel wire rope 1 at intervals, and fixed with glue to obtain a semi-finished wire saw. Then coat a layer of polyurethane glue 5 on the space between the semi-finished products of the wire saw, and make such as Figure 4 The diamond wire saw shown in .

[0073] like Figure 4 and Figure 9 As shown in , a diamond wire saw includes a multi-strand steel wire rope 1 resistant to bending. The diameter of the steel wire rope 1 is 0.5-2.0 mm, and several diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com