Method for producing functional nylon-6 slice

A production method and functional technology, applied in the field of nylon 6 production, can solve the problems of extremely high raw material requirements, raw material consumption, and few additives, and achieve the effects of low content, short stop time, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

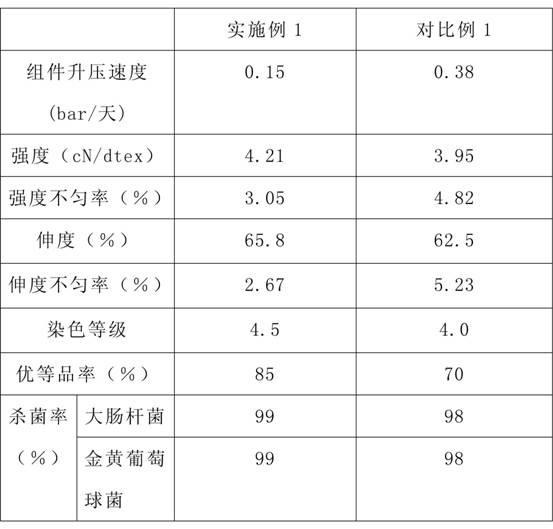

[0028] Caprolactam and molecular weight regulator acetic acid are added together at a rate of 21.384kg / h into the polymerization tube 1 continuously, the polymerization temperature is 245-275°C, and the melt flowing out of the bottom of the polymerization tube is metered into the twin-screw extruder 9 through the melt pump 2 In the process, 20kg of nano zinc oxide silver-loaded powder is added to the batching tank 4 with 80kg of caprolactam at 80°C through the feeding hopper 3, stirred and mixed evenly to form a rough mixture, and the rough mixture is input into the stirring and grinding machine 6 through the screw pump 5 , the grinder is kept at 70°C, the ground material is placed in a stirred intermediate tank 7, and then metered and transported to the twin-screw extruder 9 by the plunger pump 8 at a speed of 1kg / h, and the two strands of material are mixed by the twin-screw, Extruded after dispersion, pressurized by melt pump 2, filtered by melt filter 10, and cut into pelle...

Embodiment 2

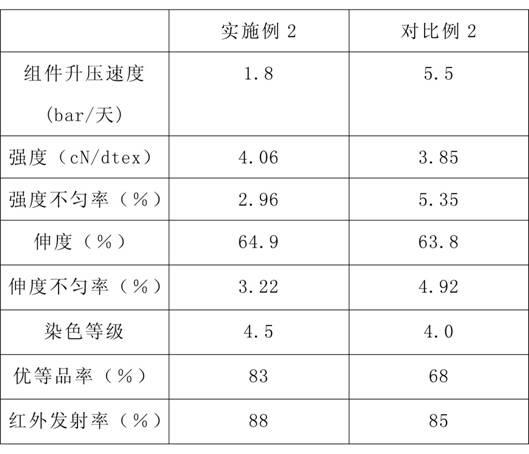

[0033] Caprolactam and molecular weight regulator acetic acid are added together at a rate of 21.168kg / h into the polymerization tube 1 continuously, the polymerization temperature is 245-275°C, and the melt flowing out of the bottom of the polymerization tube is metered into the twin-screw extruder 9 through the melt pump 2 In the process, 20kg of medical stone powder is added to the batching tank 4 with 80kg of caprolactam insulated at 80°C through the feeding hopper 3, stirred and mixed evenly to form a rough mixture, which is input into the stirring grinder 6 through the screw pump 5, and ground The machine is kept at 70°C. The ground material is placed in the intermediate tank 7 with stirring, and then is metered and transported to the twin-screw extruder 9 by the plunger pump 8 at a speed of 2kg / h. The two strands of material are mixed and dispersed by the twin-screw. Extruded, pressurized by melt pump 2, filtered by melt filter 10, and cut into pellets. The diced produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com