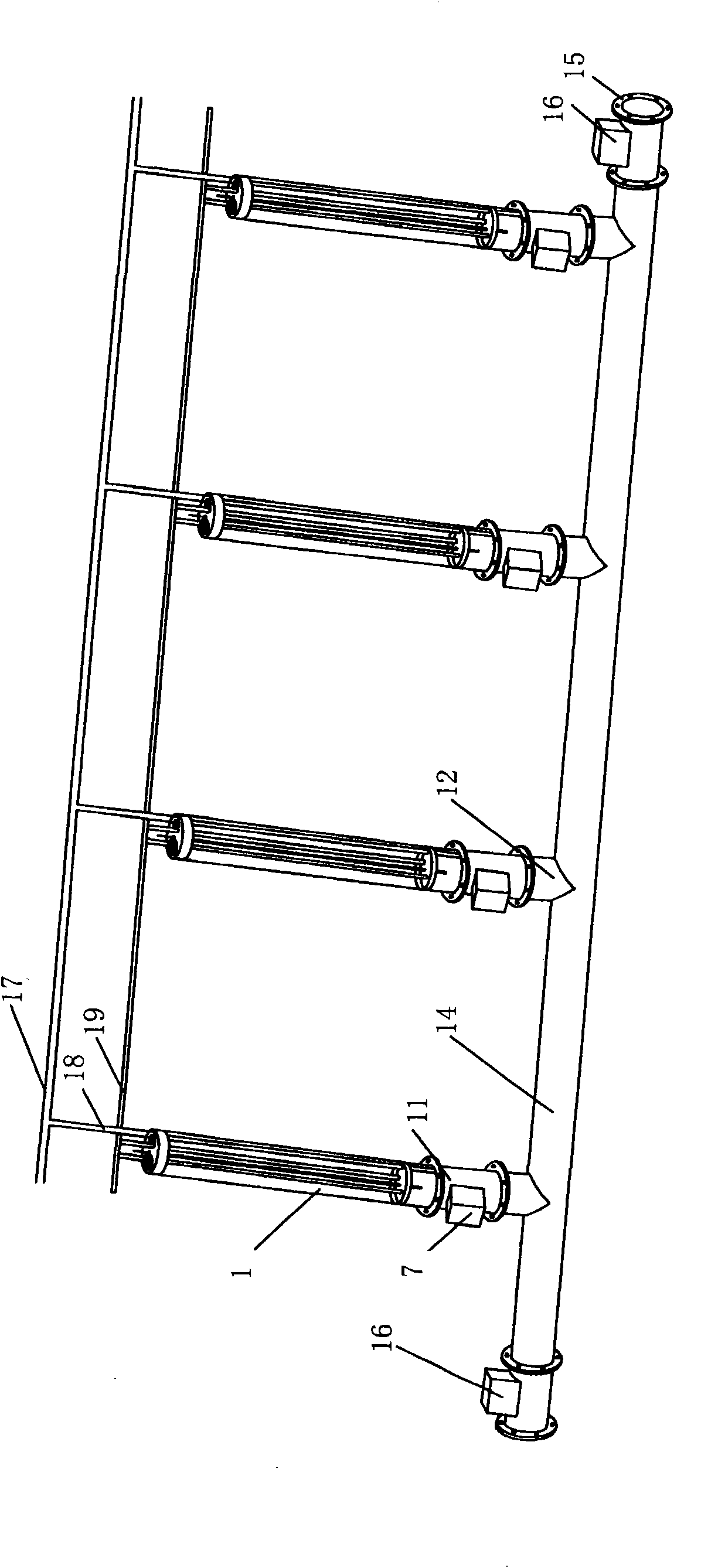

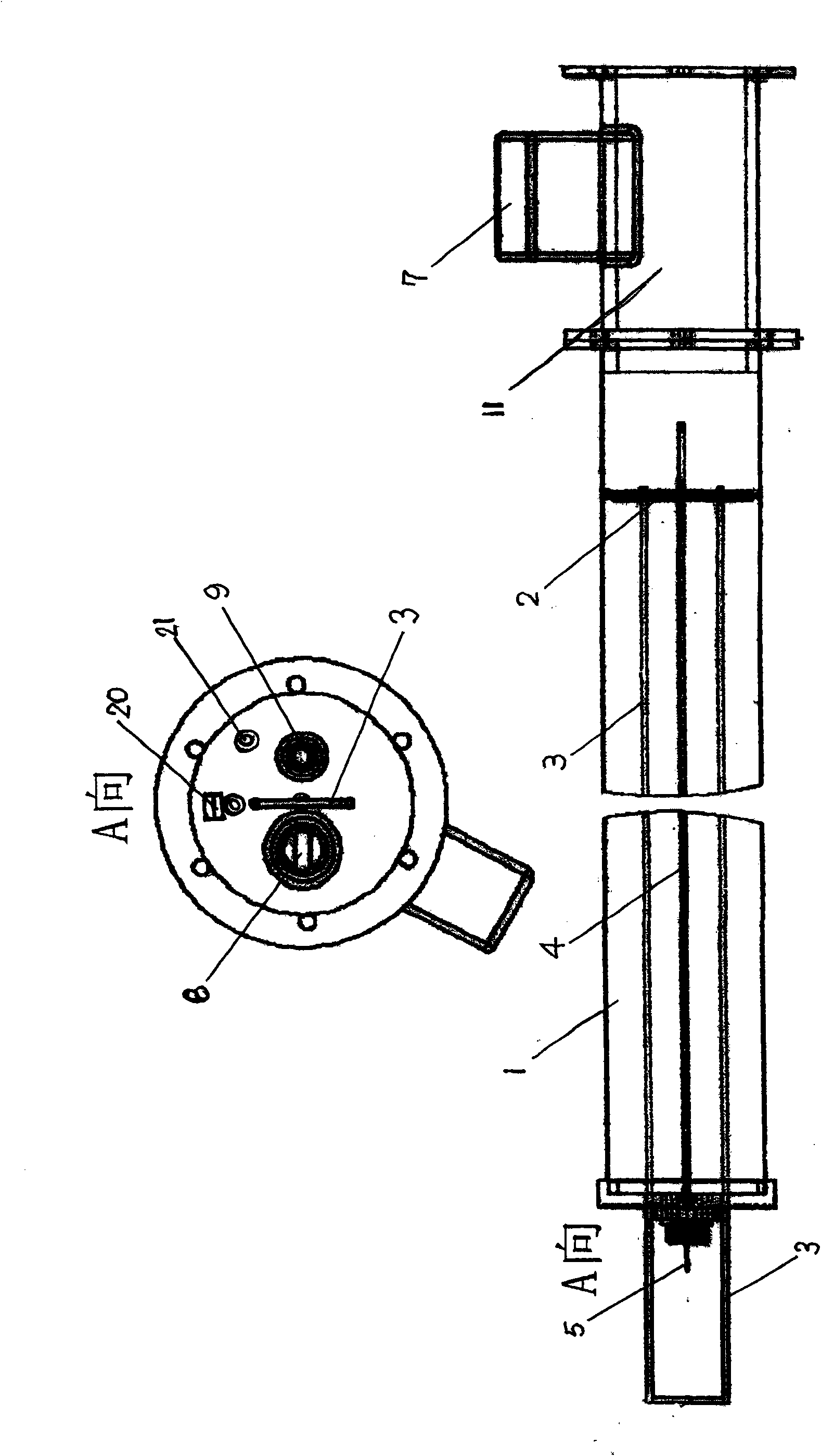

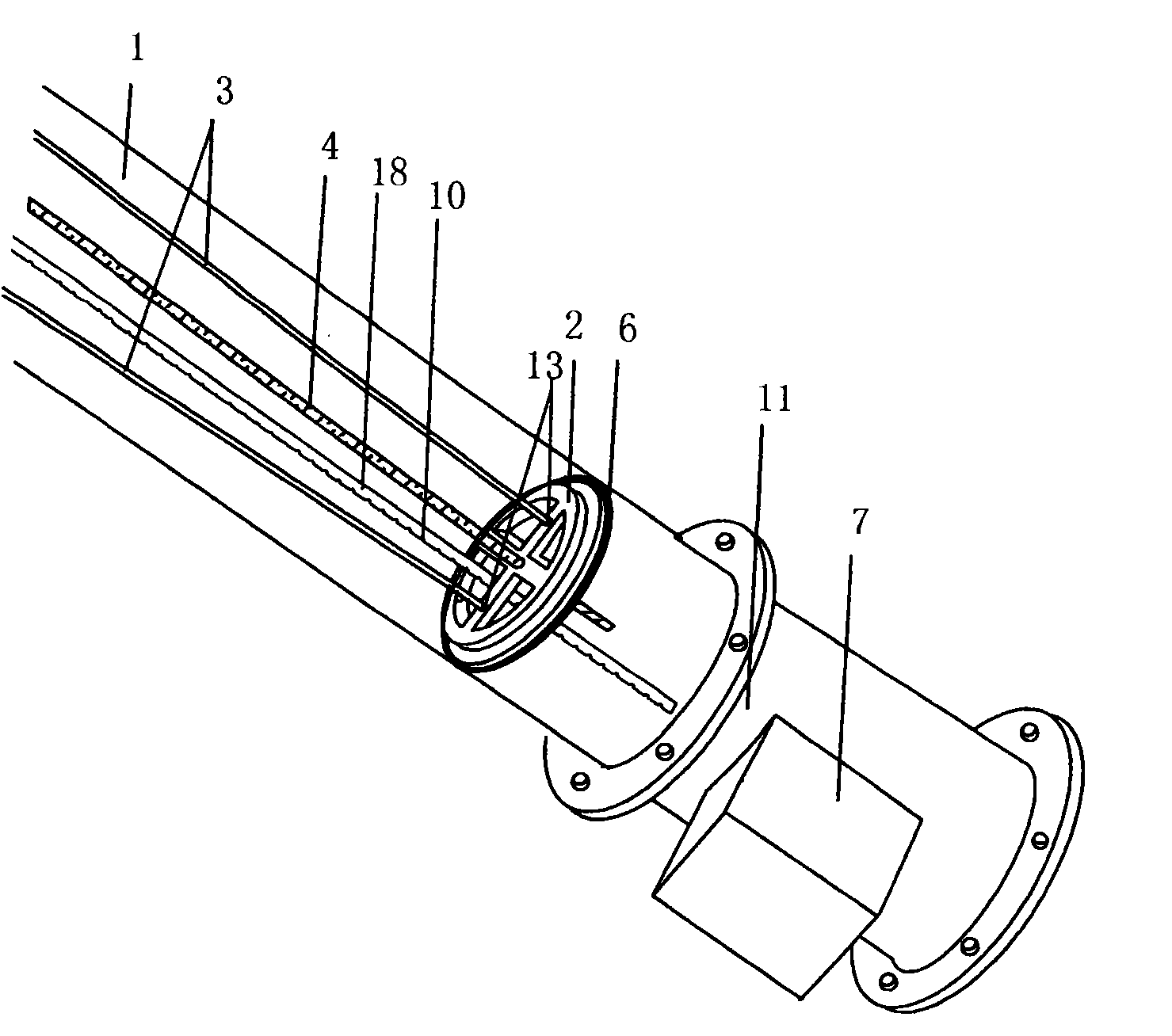

Seal type pipeline culture device of bait microalgae and microalgae pipeline culture method

A technology for culturing device and feeding microalgae, which is applied in the fields of microalgae biotechnology and sewage treatment, can solve the problems of restricting the enlarging application of closed-pipe photobioreactor, hindering the normal flow of algae, and oxidative damage of algal cells, etc., and achieves high-efficiency all-weather Cultivation, meeting the needs of growth and reproduction, and the effect of stable growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] According to the production device for cultivating microalgae provided by the present invention, the microalgae is microalgae with high lipid content such as green algae, Haematococcus, Haematococcus pluvialis, diatoms or Cyanococcus. Inoculation of algae liquid is 1 / 60 of the volume of the reactor, in which the microalgae liquid can not need each external inoculum, only need to collect 3 / 4 to 99 / 100 of the cultured microalgae liquid each time, and the rest is the following Inoculated microalgae in the subculture.

[0056] CO required in the microalgae culture of the present invention 2 The gas comes from CO emitted from power plants or farming processes 2 The gas source is treated to remove the impurity gas and particulate (including dust) substances contained in the gas that are not conducive to the reproduction of microalgae, and the CO from the power plant 2 Abundant, cheap, and hot CO 2 , available via hot CO 2 or heating CO 2 To adjust the culture temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com