Sandy wall rock grouting strengthening method in subsurface excavation construction

A grouting reinforcement and grouting technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of quicksand, collapse, and sand leakage in the excavation surface of the sand layer, and achieve low grout loss, strong permeability, The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

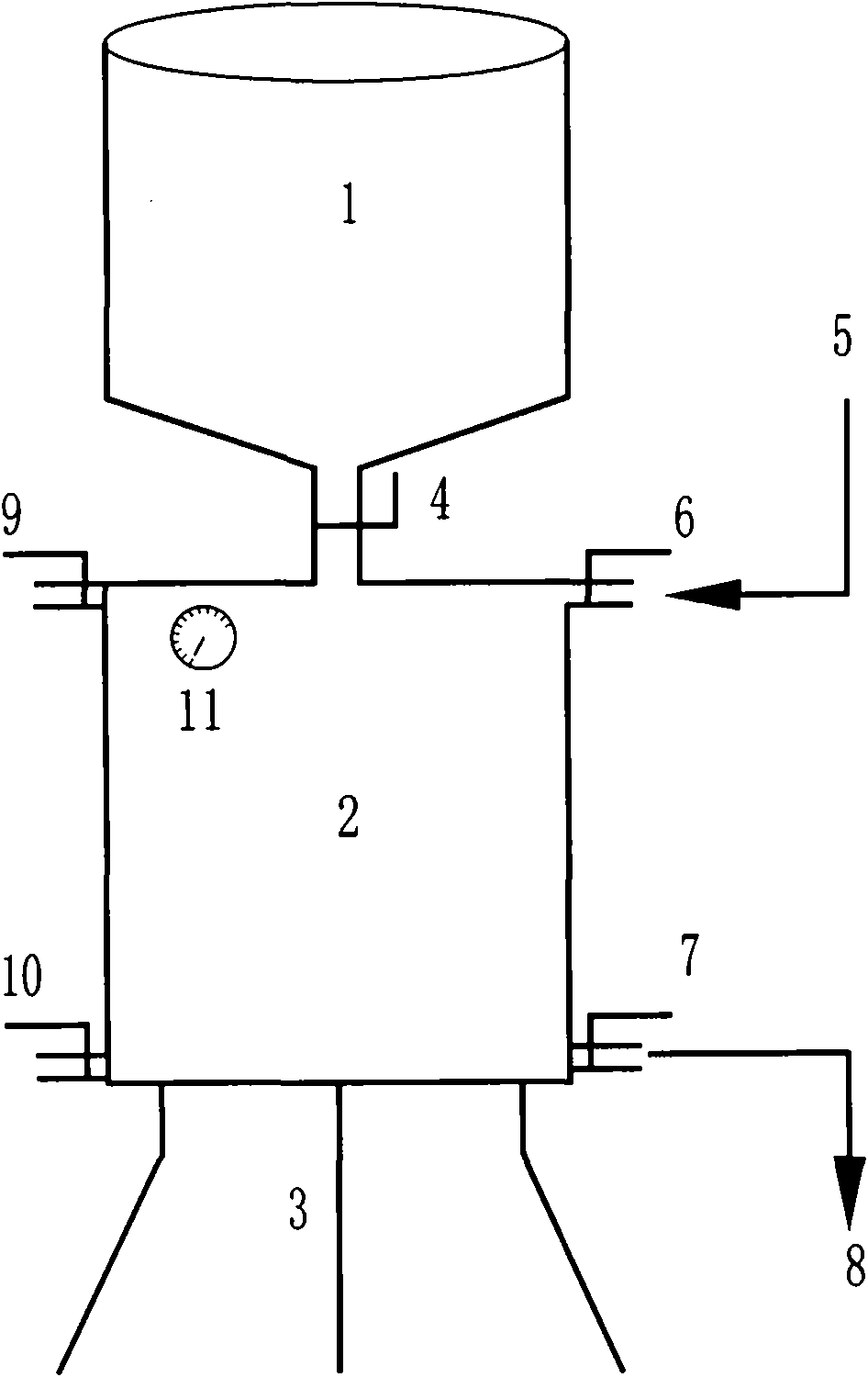

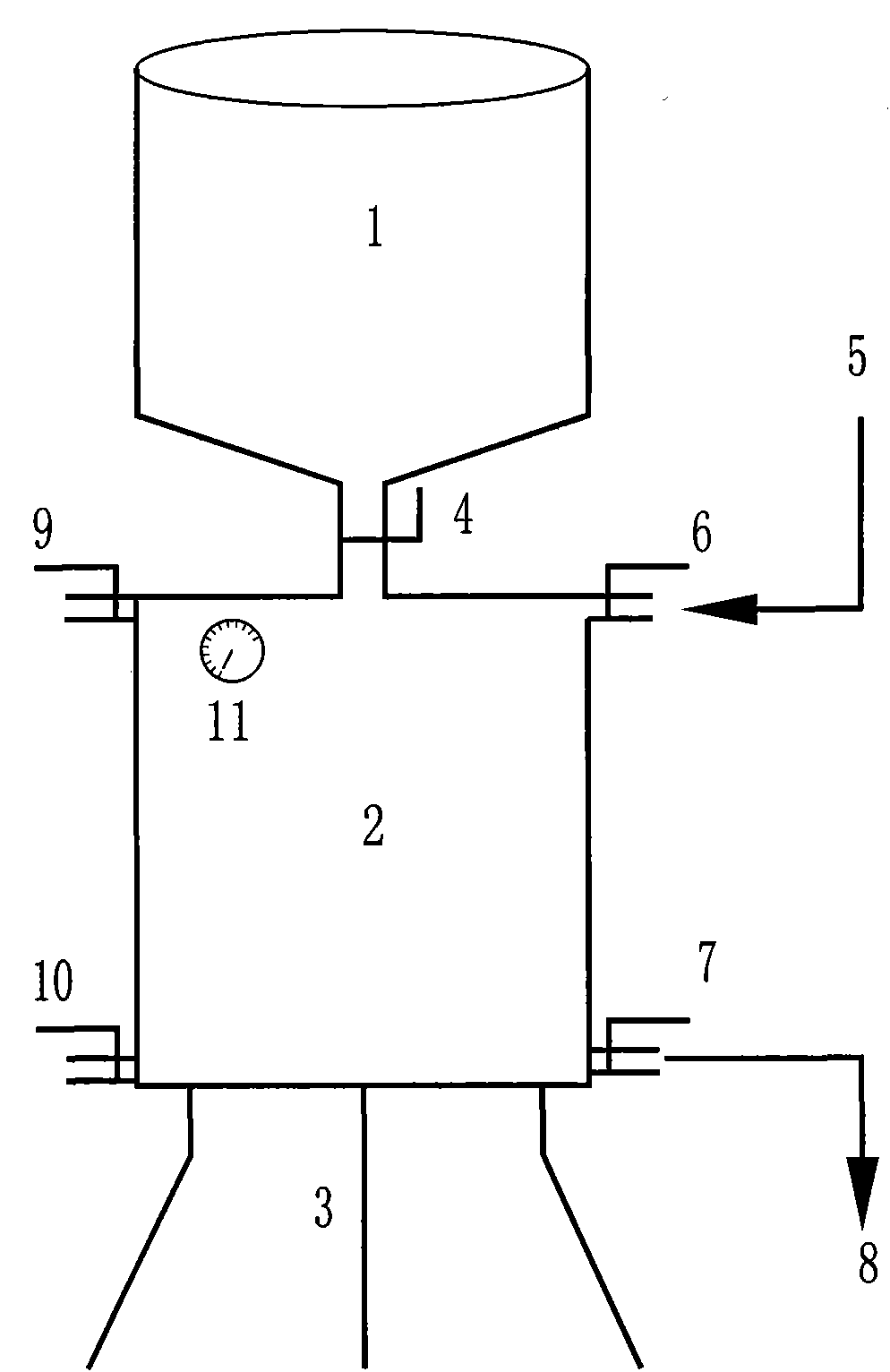

Image

Examples

Embodiment

[0060] The section of the submerged tunnel between XX Station and XX Station of XX Subway Line 1 is all located in the sand layer, and the sand layer is rich in water. The invention was adopted in the underground excavation construction process of the subway tunnel, and successfully overcome the difficult problems of underground excavation tunnel construction in sandy strata such as tunnel collapse, vault sand loss, and arch foot quicksand. The project started in April 2006 and was completed in July 2007 The excavation was successfully completed.

[0061] The construction process is as follows:

[0062] The diameter of the grouting pipe is 42mm, and the length is 1.5m. Drill 28 holes in the pipe body in a plum blossom shape with a drilling machine. The front end of the grouting pipe is processed into a cone shape, and the tapered part is filled with cotton yarn.

[0063] After the grille is installed, install the grouting pipe. The grouting pipe is positioned by marking it wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com