High-frequency combustion instability coverall process simulation test automatic regulating system and method

An unstable and simulated test technology, applied in machines/engines, rocket engine devices, jet propulsion devices, etc., can solve the problems of high-frequency combustion instability, poor safety performance, high cost, and improve the level of automatic operation and parameters. Stable and guaranteed effect of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Technical scheme of the present invention is realized like this:

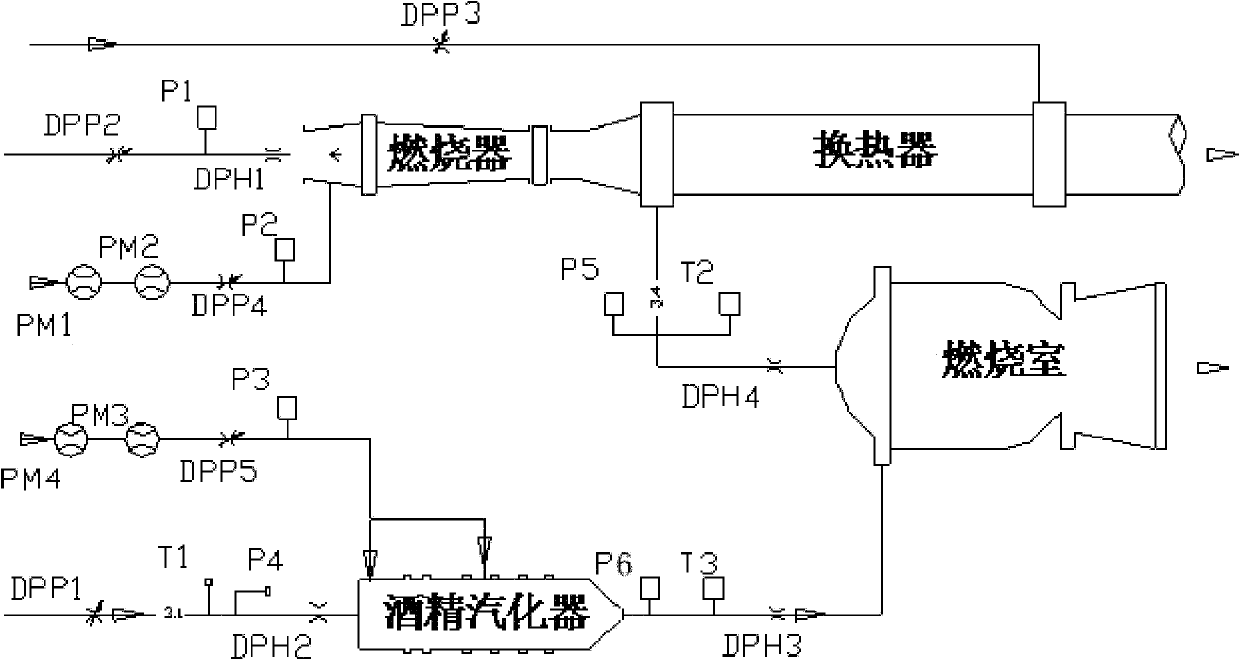

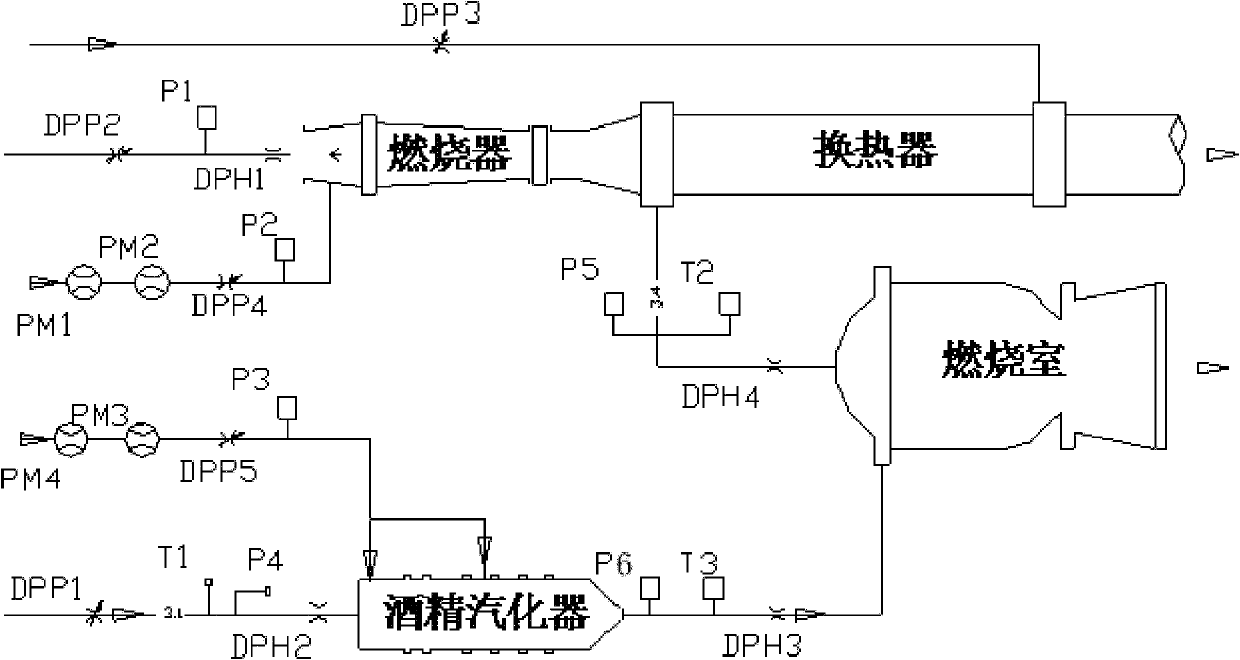

[0034] High-frequency combustion instability whole process simulation test automatic adjustment system, including control system, burner, heat exchanger, alcohol vaporizer, combustion chamber.

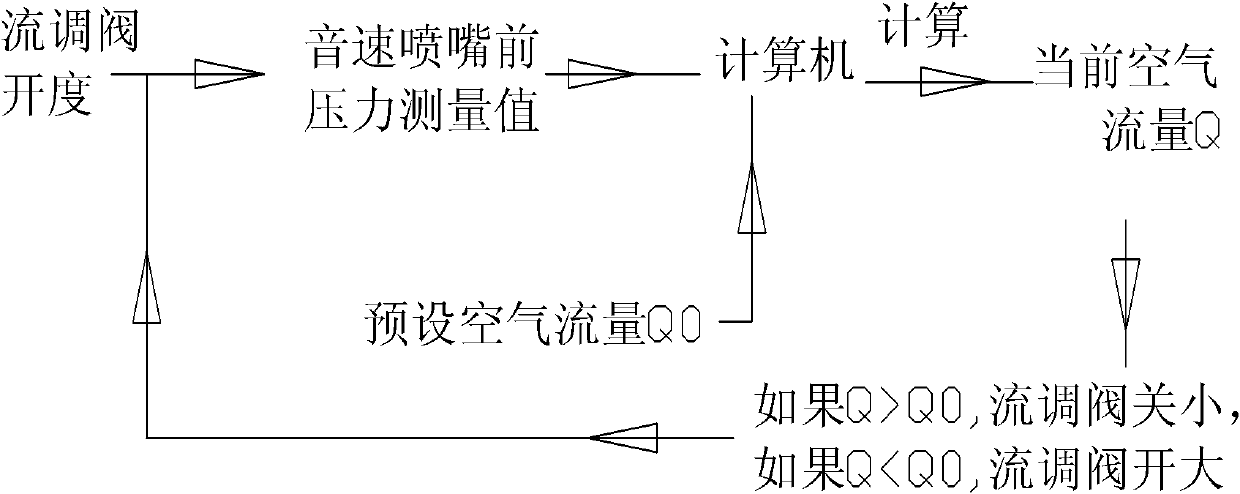

[0035] The combustion chamber is the head of the engine in real size, and its oxidant inlet and fuel inlet are connected to the heat exchanger and the alcohol vaporizer respectively. The oxidant and fuel are pure hot air at 350-450°C and alcohol vapor at a temperature of about 400°C. The remaining oxygen coefficient ranges from 0.6 to 1.1 during work. The hot air is provided by the heat exchanger, and after the cold air is heated by the heat exchanger, the hot air with a pressure of about 5MPa is formed and supplied to the combustion chamber. A sonic orifice DPH4, a pressure measuring point P5 and a temperature measuring point T2 are set at the oxidant inlet of the combustion chamber, and a sonic orifice DPH3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com