Making method and system of semi-conductor device

A manufacturing method and semiconductor technology, which are applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of limited increase, limit the improvement of HTO quality, limited number of structures, etc., and achieve the effect of improving quality and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In view of the problems mentioned in the background technology, the embodiment of the present invention proposes the following design ideas: if after the HTO is formed, an appropriate reactant is selected for annealing treatment to provide more oxygen atoms to enter the HTO to correct the defect structure in the HTO, Then, compared with the prior art, the number of corrected defect structures can be greatly increased, thereby improving the quality of the HTO, and further improving the quality of the semiconductor device.

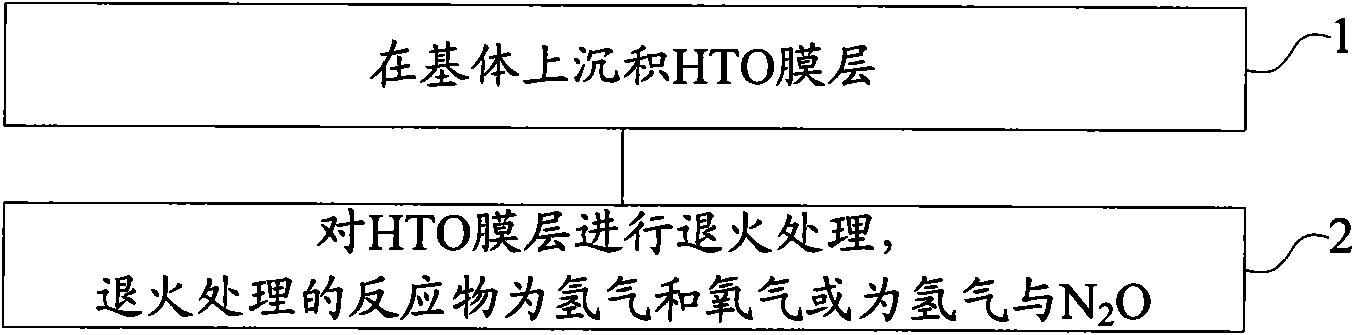

[0018] figure 1 The flowchart of the semiconductor device manufacturing method provided by the embodiment of the present invention, combined with this figure, based on the above design idea, the manufacturing method includes steps:

[0019] Step 1, depositing the HTO film layer on the substrate. The substrate represents the structure that has been produced before depositing the HTO film layer in the process of manufacturing semiconductor devices. The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap