Winding change-over switch of three-phase AC motor

A three-phase AC and winding switching technology, which is applied in the direction of AC motor control, electromechanical transmission control, motor generator control, etc., can solve the problems of instantaneous current switching, induced voltage rise, overcurrent, etc., and prevent abnormal operation and device damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

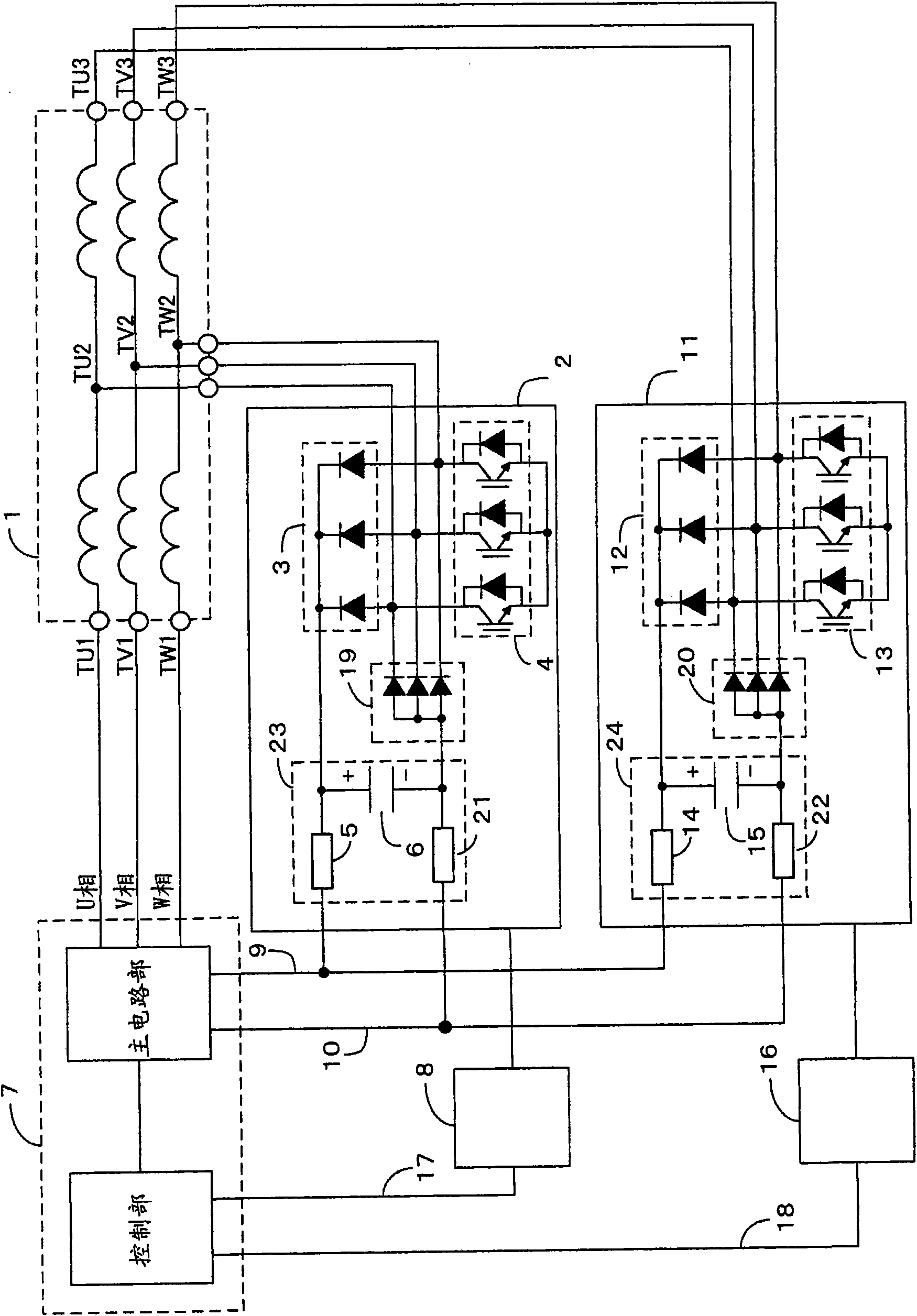

[0032] figure 1 It is a figure which shows the 1st Example of the winding switching device of the three-phase AC motor of this invention. exist figure 1 Among them, 1 is a three-phase AC motor, 2 and 11 are winding switching parts, 3 and 12 are diode parts, 4 and 13 are switching parts, 5 and 14 are positive charging resistors, 6 and 15 are capacitors, and 7 is reverse 8 and 16 are drive circuits, 9 is a DC positive side bus, 10 is a DC negative side bus, 17 and 18 are drive signals, 21 and 22 are negative side charging resistors, and 23 and 24 are potential fixing parts.

[0033] The inverter 7 is composed of a control unit and a main circuit.

[0034] For the three-phase AC motor 1, one center tap (TU2, TV2, TW2) for each phase winding, winding start terminal (TU1, TV1, TW1) and winding end terminal for each phase winding are provided outside the motor. Terminals (TU3, TV3, TW3).

[0035] The winding start terminals (TU1, TV1, TW1) of the windings of each phase of the ...

Embodiment 2

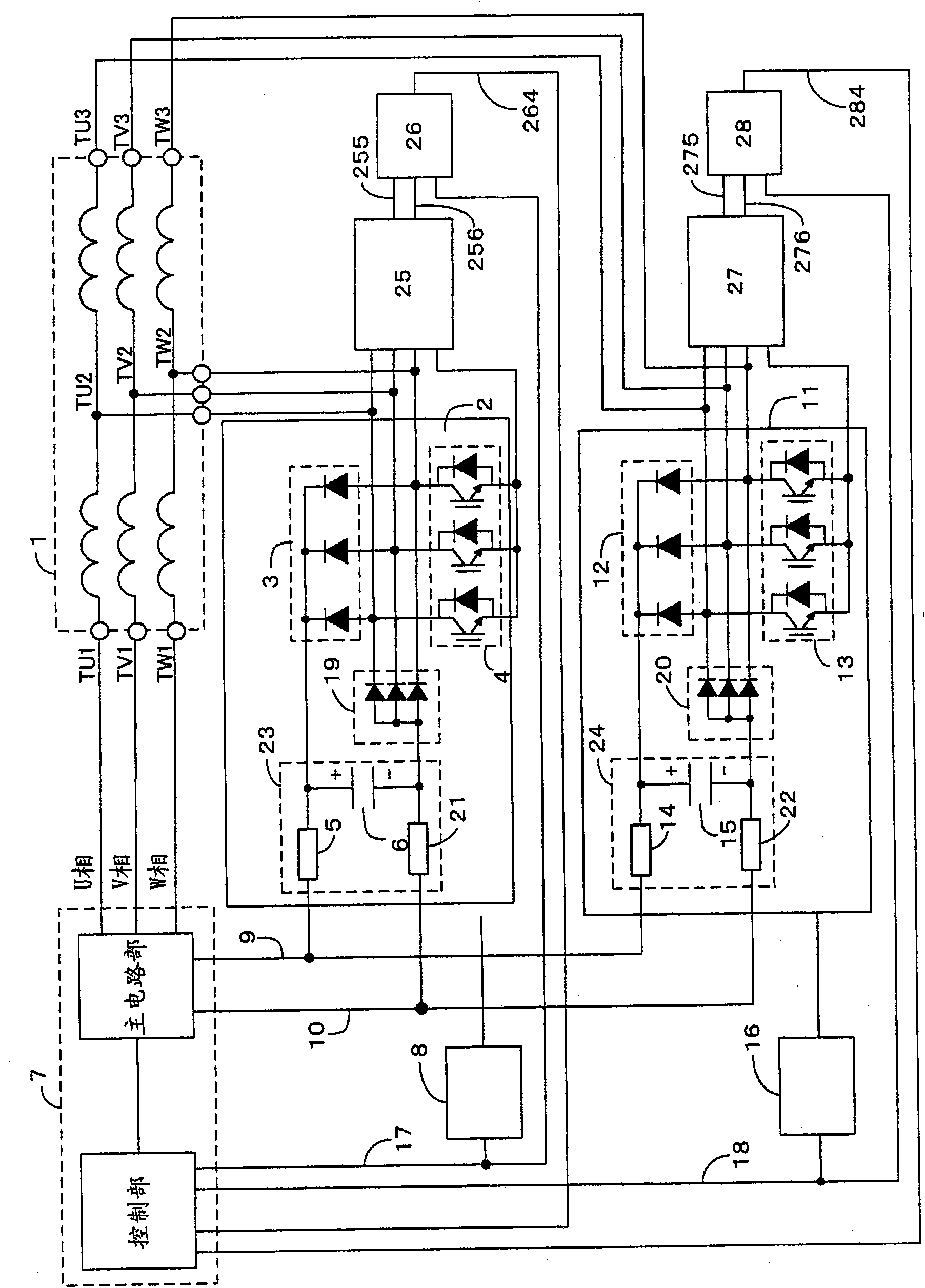

[0094] image 3 It is a figure which shows the 2nd Example of the winding switching device of the three-phase AC motor of this invention. exist image 3 Among them, 25 and 27 are state detectors, 26 and 28 are comparators, 255 and 275 are winding switching part on-state signals, 256 and 276 are * Winding switching unit off-state signal, 264 and 284 are winding switching unit abnormal signals.

[0095] The difference from Embodiment 1 is that, in this embodiment, there are: a state detector, which detects the conduction state of each power semiconductor switching element constituting the switch portion in the winding switching portion; a comparator, which detects the conduction state according to the state. The detection result of the inverter and the drive signal output from the control unit of the inverter are used to detect the abnormality of the winding switching unit.

[0096] First, an outline of the operation of the state detector and the comparator will be described....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com