Method for continuously fermenting pickle with low salt

A technology of kimchi and kimchi liquid, applied in application, food preparation, food science and other directions, can solve the problems of high labor intensity, hidden dangers of product safety, long fermentation cycle, etc., to improve quality and safety, shorten fermentation cycle, fermentation cycle the effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

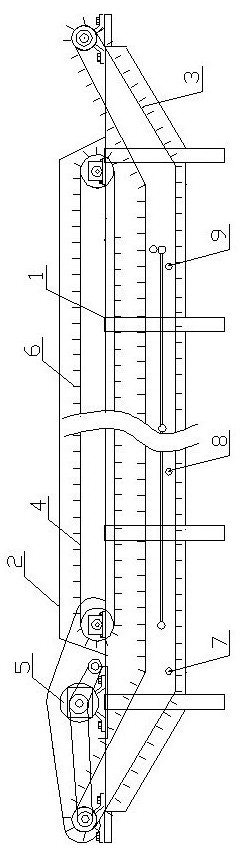

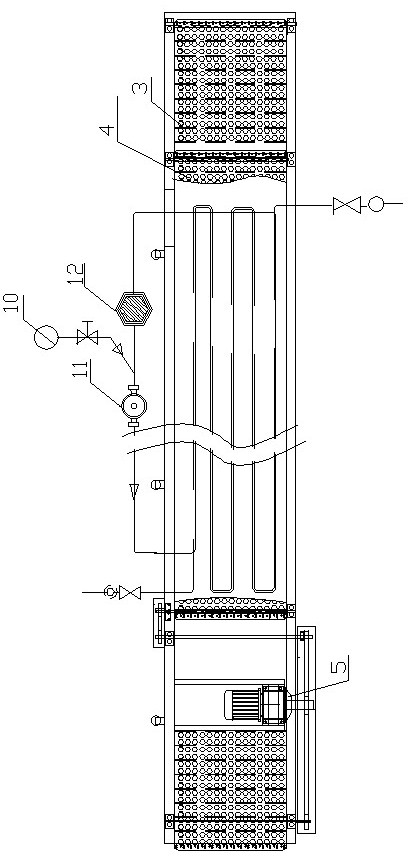

Method used

Image

Examples

Embodiment 1

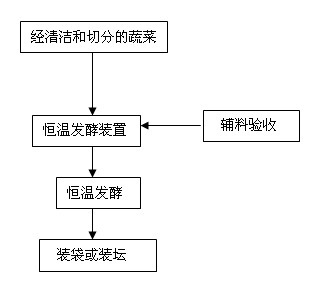

[0025] Embodiment 1: a kind of method of continuous low-salt fermented pickled vegetables, comprises the following steps:

[0026] A. Clean and cut the fresh vegetables to be fermented;

[0027] B. Add pickle liquid to the constant temperature fermentation device, the pickle liquid contains by weight: 1% to 7% salt, 0 to 1% spices, 0% to 1% special functional bacterial powder for pickles, 0.1 to 2% Carbohydrates, 0.2-2% yeast extract, 0%-0.03% sodium dehydroacetate, the rest of water, at 5°C-43°C, culture for 0.5h-48h;

[0028] C. Put the cleaned and cut vegetables in step A into a constant temperature fermentation device, submerge the vegetables in the pickle solution, and ferment for 0.1h-90h at 5°C-43°C to obtain the required pickles.

[0029] In the step B, the pickle liquid contains by weight percentage: 2% to 6% salt, 0.1 to 0.2% spices, 0.03% to 0.5% special functional bacteria powder for pickles, 0.5 to 1.5% carbohydrates, 0.5 to 1.5% % yeast extract, 0.01% ~ 0.03% s...

Embodiment 2

[0032] Embodiment 2: a kind of method of continuous low-salt fermented pickled vegetables, comprises the following steps:

[0033] A. Clean and cut the fresh vegetables to be fermented;

[0034] B. Add pickle liquid to the constant temperature fermentation device. The pickle liquid contains by weight: 2% salt, 0.1% spice, 0.03% special functional bacteria powder for pickle (developed by Sichuan Food Fermentation Research Institute), 1.5% glucose , 1.5% yeast extract, the rest of the water, at 38 ° C, enrichment culture for 6 hours;

[0035] C. Put the cleaned and cut vegetables in step A into a constant temperature fermentation device, submerge the vegetables in the pickle solution, and ferment for 5 hours at 38° C. to obtain the required pickles.

[0036] In the step B, the spice is one or more of Chinese prickly ash, aniseed or star anise. In the step B, the special functional bacterial powder for kimchi is one or more of Lactobacillus plantarum, Lactobacillus brevis and L...

Embodiment 3

[0038] Embodiment 3: a kind of method of continuous low-salt fermented pickled vegetables, comprises the following steps:

[0039] A. Clean and cut the fresh vegetables to be fermented;

[0040] B. Add pickle liquid to the constant temperature fermentation device, the pickle liquid contains by weight percentage: 6% salt, 0.5% special functional bacteria powder for pickle (developed by Sichuan Food Fermentation Research Institute), 0.5% sucrose, 0.5% yeast extract extract, 0.02% sodium dehydroacetate, and the rest of water, at 43°C, enrich the culture for 0.5h;

[0041] C. Put the cleaned and cut vegetables in step A into a constant temperature fermentation device, submerge the vegetables in the pickle solution, and ferment for 72 hours at 5° C. to obtain the required pickles.

[0042] In the step B, the special functional bacterial powder for kimchi is one or more of Lactobacillus plantarum, Lactobacillus brevis and Leuconostoc enterococci. In the step C, the salinity is kep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com