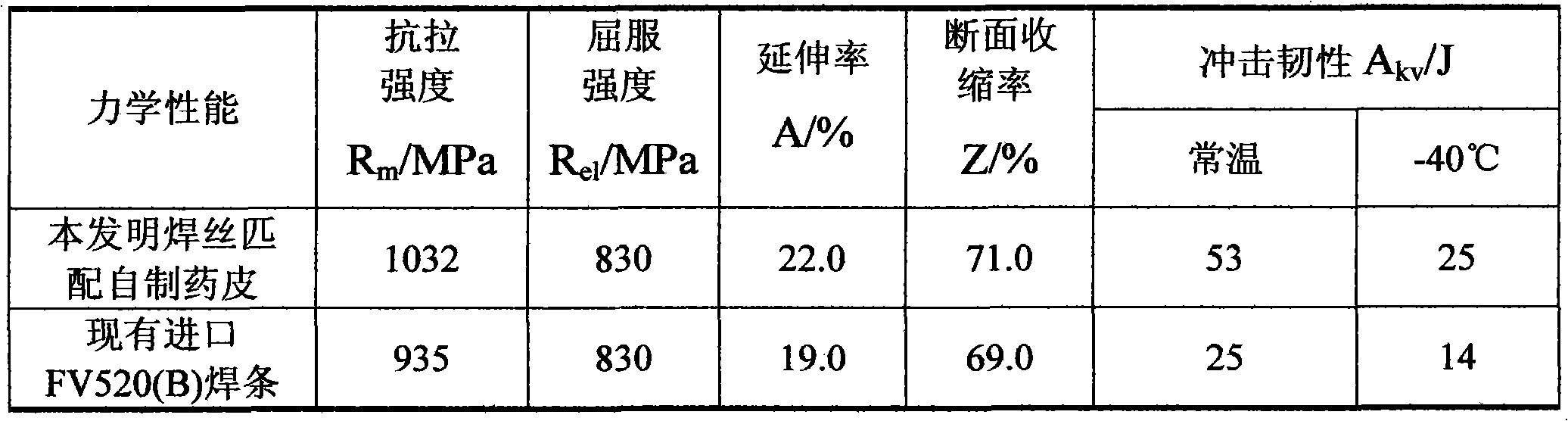

Low-hydrogen basic electrode for manual metal arc welding of FV520 (B) stainless steel

A FV520, alkaline electrode technology, used in arc welding equipment, welding/welding/cutting items, welding media, etc., can solve the problem of lack of welding electrodes, and achieve good molten pool fluidity, good low temperature toughness, and high weld strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1, make stainless steel welding core

[0035] The preparation weight ratio is 1:1 for professional pure iron and industrial pure iron. The ores containing C, Si, Mo, Cr, and Nb are packed around and above the magnesia crucible in the induction furnace. Ni powder is packed in the middle of the crucible, and Cu, Re, Mn, and B are put into the tray. The carbon in the crucible acts as a deoxidizer. Put the pure iron and the material in the crucible into an induction furnace for smelting. When the pure iron is completely melted, the alloy steel temperature reaches 1540℃, and the molten steel is calm, the power is cut off and the exhaust is cooled for 15 minutes; then the power is sent for refining, and after 20 minutes of refining When the alloy steel temperature drops to 1550℃, add Ti powder and the temperature continues to drop to the tapping temperature (the tapping temperature is 1540℃) before tapping. Fill the furnace with argon 5min before tapping to make the furna...

Embodiment 2

[0045] Step 1, make stainless steel welding core:

[0046] The preparation weight ratio is 1:1 for professional pure iron and industrial pure iron. The ores containing C, Si, Mo, Cr, and Nb are packed around and above the magnesia crucible in the induction furnace. Ni powder is packed in the middle of the crucible, and Cu, Re, Mn, and B are put into the tray. The carbon in the crucible acts as a deoxidizer. Put the pure iron and the material in the crucible into an induction furnace for smelting. When the pure iron is completely melted, the alloy steel temperature reaches 1540℃, and the molten steel is calm, the power is cut off and the exhaust is cooled for 15 minutes; then the power is sent for refining, and after 20 minutes of refining When the alloy steel temperature drops to 1550℃, add Ti powder and the temperature continues to drop to the tapping temperature (the tapping temperature is 1540℃) before tapping. Fill the furnace with argon 5min before tapping to make the furn...

Embodiment 3

[0055] Step 1, make stainless steel welding core

[0056] The preparation weight ratio is 1:1 for professional pure iron and industrial pure iron. The ores containing C, Si, Mo, Cr, and Nb are packed around and above the magnesia crucible in the induction furnace. Ni powder is packed in the middle of the crucible, and Cu, Re, Mn, and B are put into the tray. The carbon in the crucible acts as a deoxidizer. Put the pure iron and the material in the crucible into an induction furnace for smelting. When the pure iron is completely melted, the alloy steel temperature reaches 1540℃, and the molten steel is calm, the power is cut off and the exhaust is cooled for 15 minutes; then the power is sent for refining, and after 20 minutes of refining When the temperature of the alloy steel drops to 1550℃, add Ti powder, and the temperature continues to drop to the tapping temperature (the tapping temperature is 1540℃) before tapping. Fill the furnace with argon 5min before tapping to make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com