Method for preparing porous carbon and white carbon black by using diatomite

A technology of diatomite and porous carbon, which is applied in the direction of silicon oxide and silicon dioxide, can solve the problems of inefficient utilization of mineral resources and damage to the unique structure of minerals, and achieve the effect of low environmental hazards and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

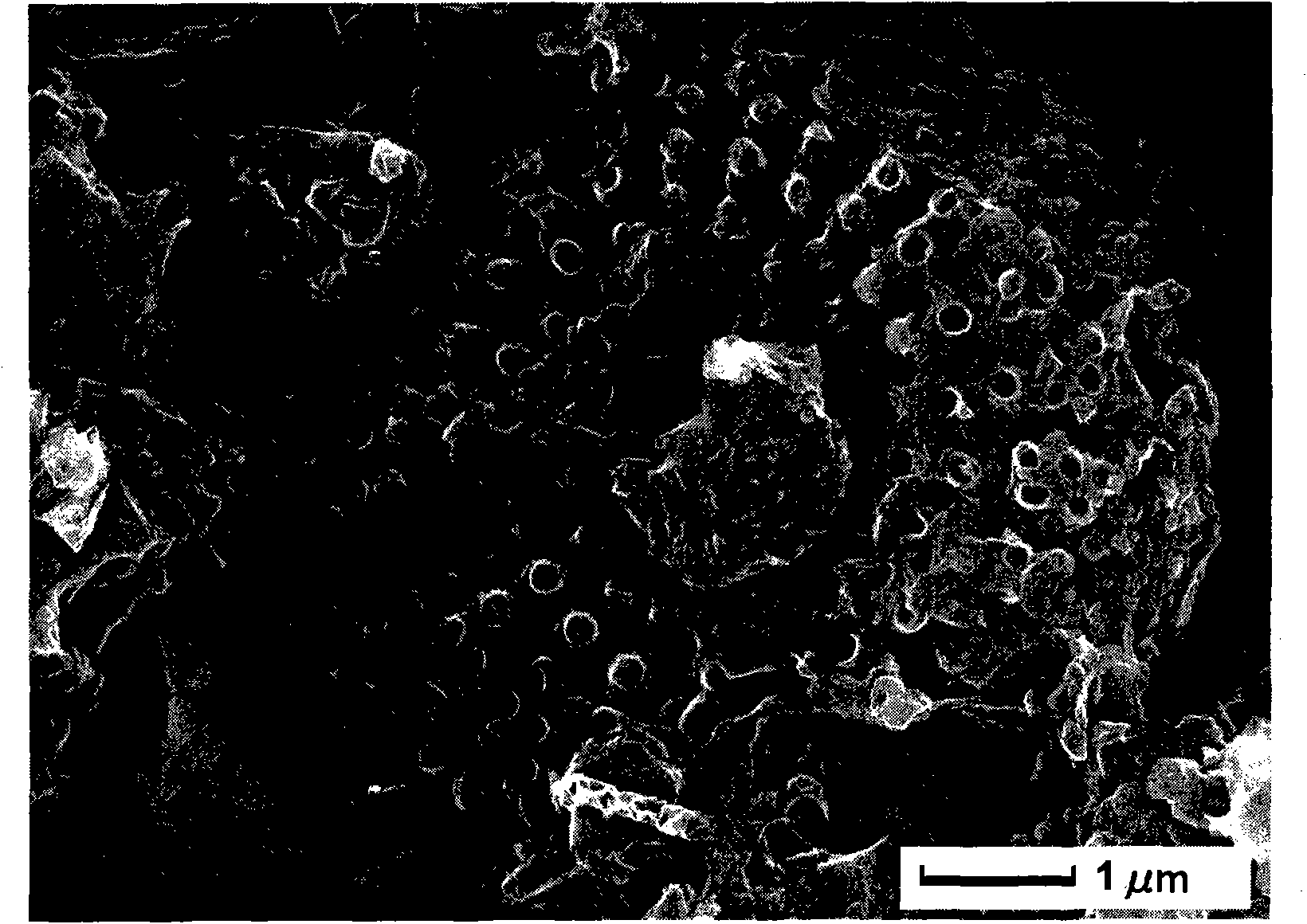

[0027] 1) Weigh 5g of Jilin diatomaceous earth raw material purified by sedimentation (the main diatom species is circumcenter diatom) at room temperature and add it to 25ml of furfuryl alcohol, and stir the resulting mixture for 1 hour.

[0028] 2) Then placed in a vacuum drying oven, heated to 95°C under vacuum, and kept constant temperature for 24 hours.

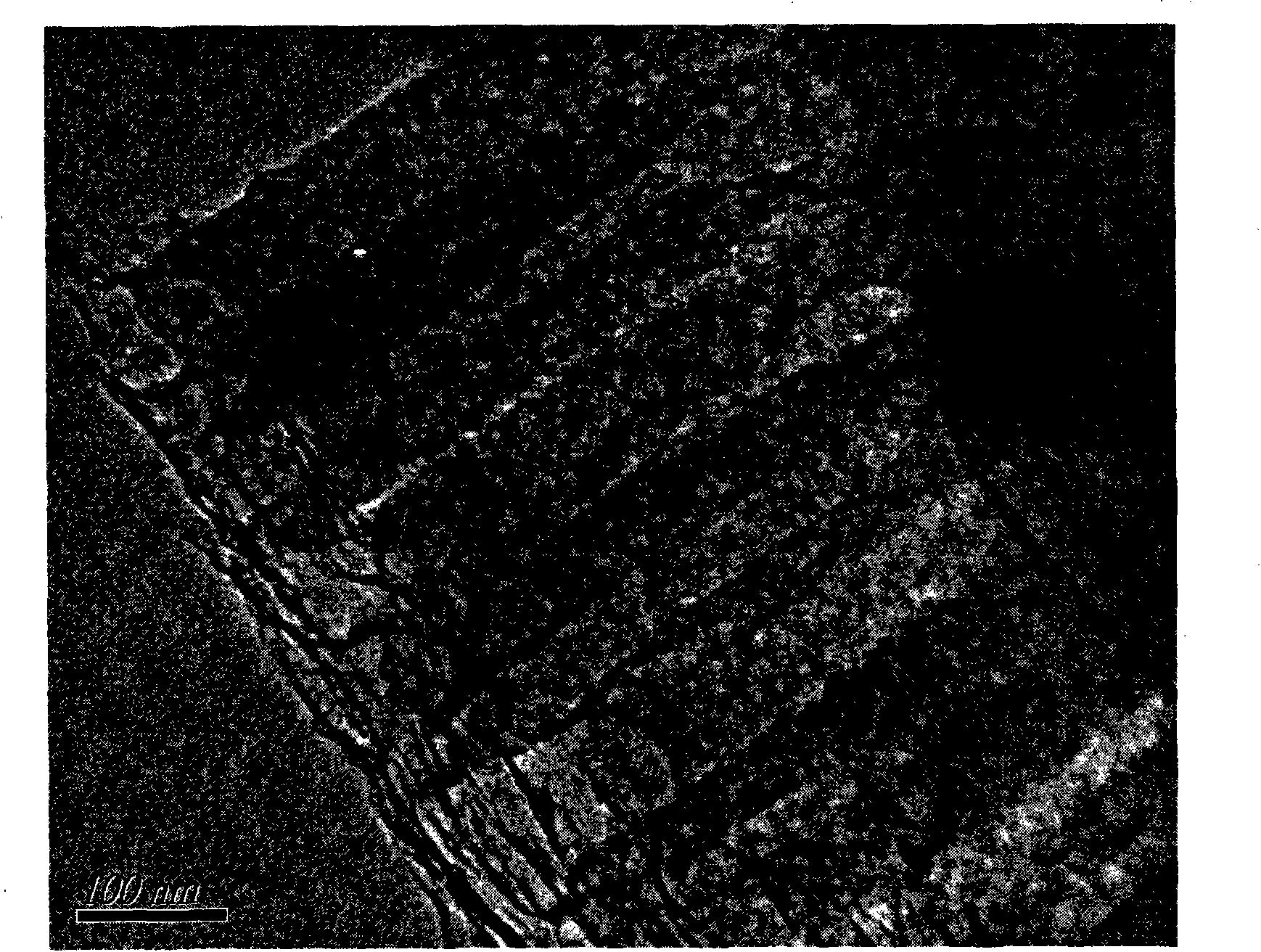

[0029] 3) Put the above-mentioned sample in a tube furnace, and raise the temperature to 700°C under an inert gas atmosphere and keep the temperature constant for 3 hours.

[0030] 4) Add the cooled solid to 100 ml of 1 mol / L sodium hydroxide solution, heat to boiling, and keep boiling for 1 hour. After cooling, the suspension was allowed to stand for 24 hours. Centrifugation, water washing, and centrifugation were repeated several times until the filtrate pH=7, and the obtained solid particles and the separated solution were stored separately.

[0031] 5) Dry the above solid to a constant weight, and grind and pulverize to obta...

Embodiment 2

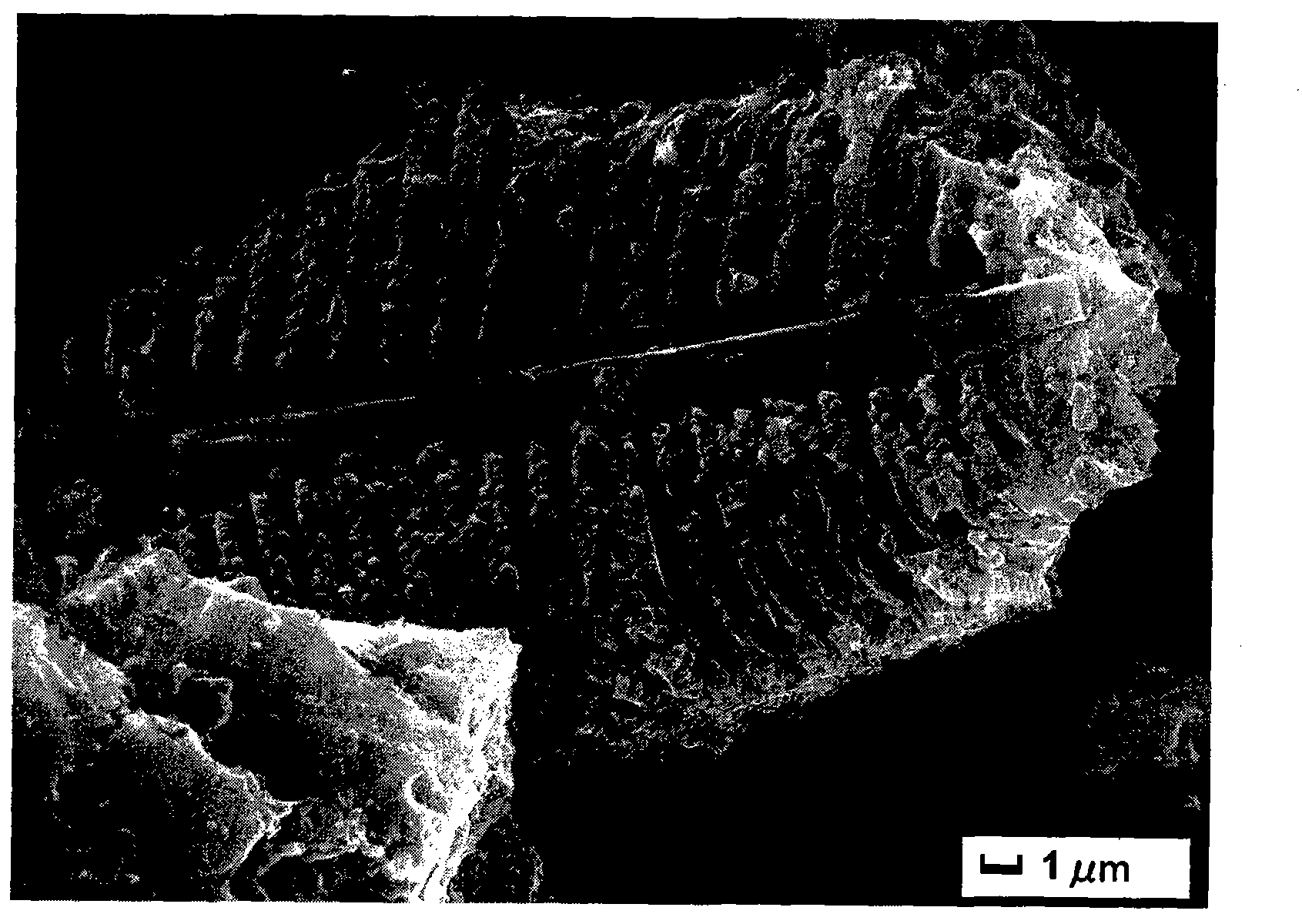

[0042] The thermal activation (calcined at 650°C for 3 hours) of Jilin diatomite was used as the template and catalyst. The preparation of activated carbon was carried out according to the steps in Example 1. The resulting activated carbon has a specific surface area of 406m 2 / g, the total pore volume is 0.348cm 3 / g.

[0043] As an implementation application, the ability of the porous carbon to adsorb hydrogen was tested, and the results showed that the hydrogen adsorption capacity of the porous carbon was 0.75wt%, and the hydrogen adsorption-desorption isotherm is shown in the attached file. Figure 5 b.

Embodiment 3

[0045] Jilin diatomaceous earth treated with acid activation (with 2mol / L hydrochloric acid, according to the ratio of liquid / soil ratio of 15ml hydrochloric acid / 1g diatomaceous earth) was used as template and catalyst. The preparation of activated carbon was carried out according to the steps in Example 1. The resulting activated carbon has a specific surface area of 426m 2 / g, the total pore volume is 0.470cm 3 / g.

[0046] As an implementation application, the ability of the porous carbon to adsorb hydrogen was tested, and the result showed that the hydrogen adsorption capacity of the porous carbon was 1.0wt%, and the hydrogen adsorption-desorption isotherm is shown in the attached file. Figure 5 c.

[0047] As an implementation application, the produced porous carbon is used to adsorb 200# gasoline. Measured its saturated adsorption capacity is 5.5g gasoline / g porous carbon, which is commercial activated carbon (specific surface area is 1013.2g / m 2 ) 1.7 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com