Hydrolysis method for producing electronic-grade special titanium white by sulfuric acid process

An electronic grade titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of large half-peak width, unable to control the average particle size of titanium dioxide, unable to meet the requirements of electronic grade special titanium dioxide, etc. Low, narrow particle size distribution, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

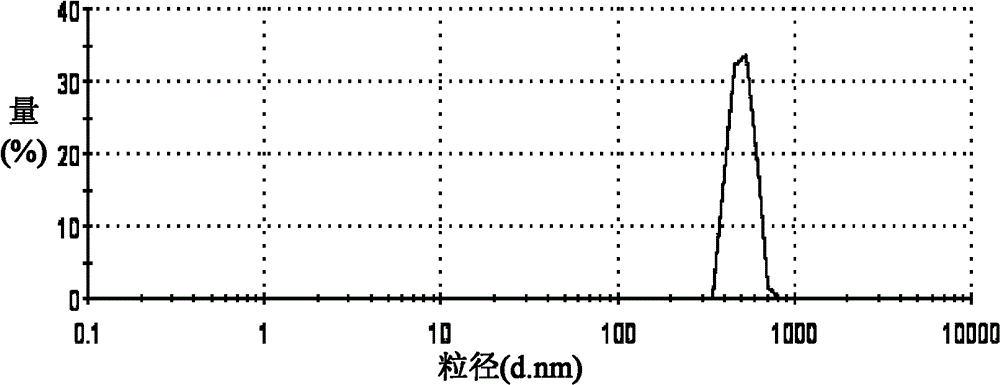

[0060] 245ml of deionized water is added in the hydrolysis pot as the bottom water, and the bottom water is preheated to 95°C, and the concentration is 162g / l (with TiO 2 meter), preheat to 80°C, add 1000ml of titanium ore titanium liquid into the hydrolysis pot at a constant speed within 12 minutes. After the feeding is complete, the hydrolysis system is heated to the first boiling point (about 103° C.), and the heating rate is maintained at 0.8° C. / min, and the heating time is 15 minutes, and the system is kept in a slightly boiling state. When the system turns steel gray (that is, the gray point), keep this state for 5 minutes, stop heating and stirring, and ripen for 25 minutes. After aging, raise the temperature of the system to the second boiling point (about 106.5°C) under stirring, keep the heating rate at 1.0°C / min, and the heating time for 16 minutes, and keep the system in a slightly boiling state, and stop the hydrolysis after 3.0 hours. The obtained hydrolyzed ma...

Embodiment 2

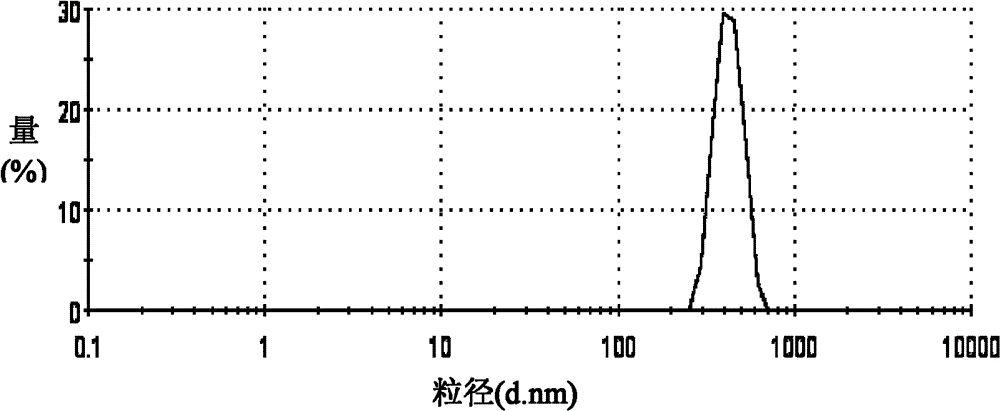

[0063] Add 333.3ml of deionized water into the hydrolysis pot as the bottom water, and preheat the bottom water to 95°C. 2 meter), preheat to 75°C, add 1000ml of titanium slag and titanium solution into the hydrolysis pot at a constant speed within 17.5min. After the feeding is complete, the hydrolysis system is heated to the first boiling point (about 104.5° C.), and the heating rate is maintained at 0.6° C. / min. The heating time is 28 minutes, and the system is kept in a slightly boiling state. When the system turns steel gray (that is, the gray point), keep this state for 12 minutes, stop heating and stirring, and ripen for 30 minutes. After aging, raise the temperature of the system to the second boiling point (about 107°C) under stirring, keep the heating rate at 2.0°C / min, and the heating time for 9 minutes, and keep the system in a slightly boiling state, and stop the hydrolysis after 2.5 hours. The obtained hydrolyzed material is pickled, bleached, washed with water, ...

Embodiment 3

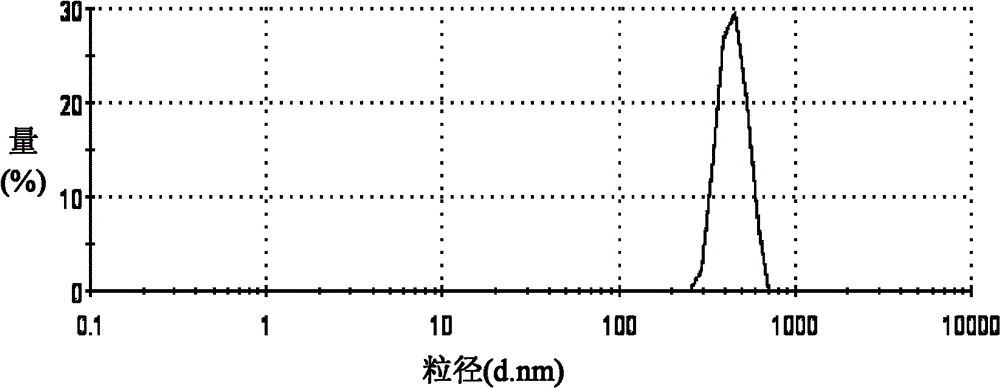

[0066] Add 300ml of deionized water into the hydrolysis pot as the bottom water, and preheat the bottom water to 88°C, and make the concentration 175g / l (with TiO 2 (meter), preheat to 88°C, mix 1000ml of slag ore with titanium solution, and add it into the hydrolysis pot at a constant speed within 20 minutes. After the feeding is complete, the hydrolysis system is heated to the first boiling point (about 104° C.), and the heating rate is maintained at 1.3° C. / min, and the heating time is 10 minutes to maintain the system in a slightly boiling state. When the system turns steel gray (that is, the gray point), keep this state for 25 minutes, stop heating and stirring, and ripen for 20 minutes. After aging, raise the temperature of the system to the second boiling point (about 107°C) under stirring, keep the heating rate at 2.3°C / min, and the heating time for 7 minutes, and keep the system in a slightly boiling state, and stop the hydrolysis after 2.8 hours. The obtained hydrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com