Small reverse osmosis seawater desalting system with energy reclaiming high-pressure pump

An energy recovery and reverse osmosis technology, applied in osmosis/dialysis water/sewage treatment, seawater treatment, pumps, etc., can solve the problem of high energy consumption, and achieve the effect of compact pump system design, high mechanical efficiency, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

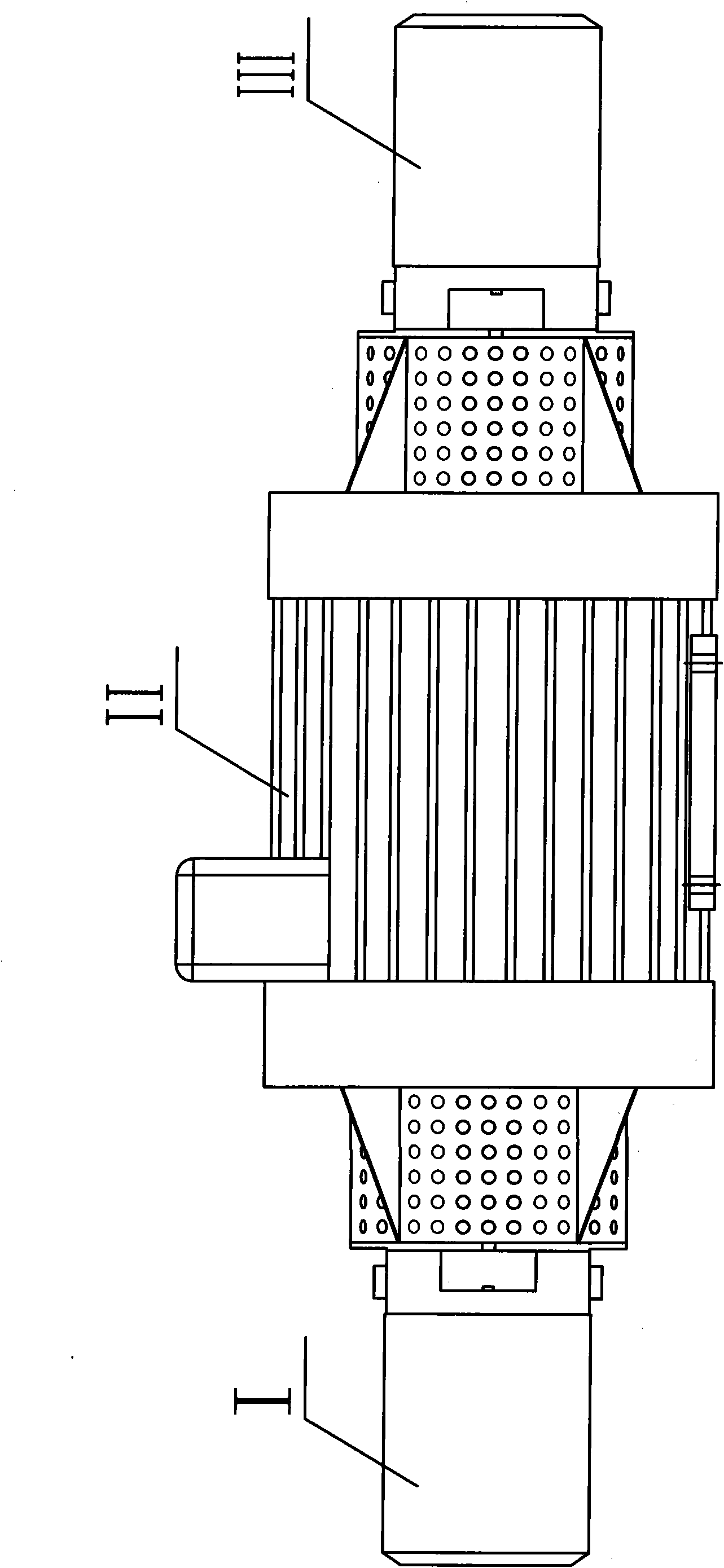

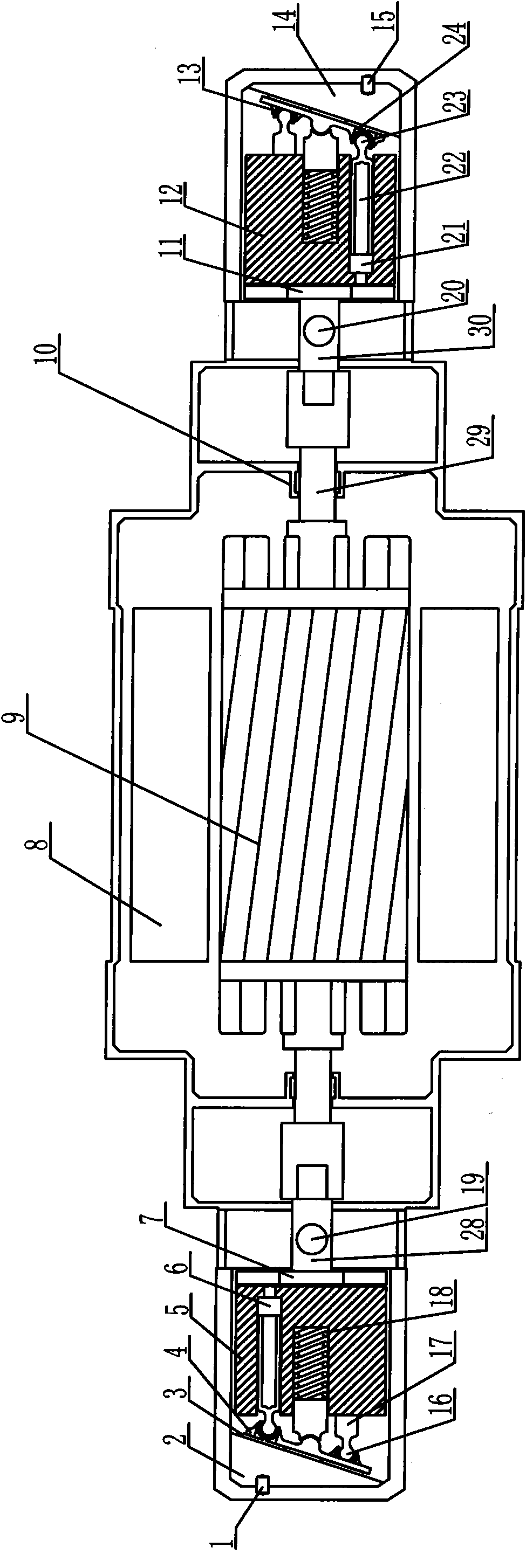

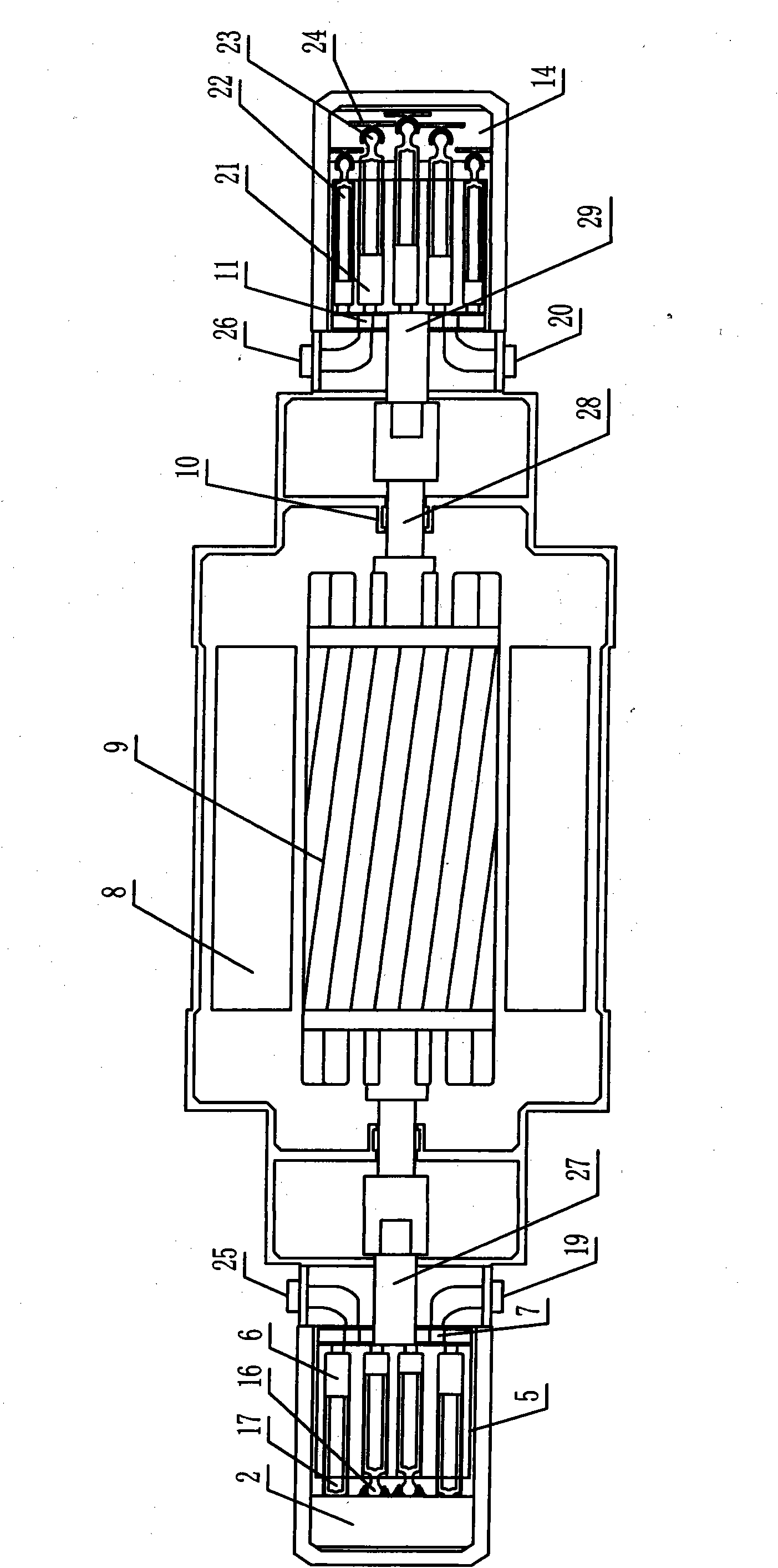

[0037] Such as figure 1 As shown, the energy recovery high-pressure pump of the small reverse osmosis seawater desalination system of the present invention includes three parts: a plunger pump head I for pressurizing raw water, a motor II, and a plunger motor III for recovering reverse osmosis high-pressure concentrated water energy ; The central axis of the above three parts can be connected to form a common rotating shaft through positioning pin 1 or other connection methods, such as figure 2 with image 3 Shown in the plunger pump center shaft 27 and motor output shaft 28 and plunger motor output shaft 29; and low-pressure raw water inlet 25, high-pressure raw water outlet 19, high-pressure concentrated water inlet 20 and low-pressure concentrated water discharge port 26.

[0038] The motor II in the present invention is a doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com