Natural plant oil based hydrophile low-resilience foam and preparation method thereof

A natural plant, oil-based hydrophilic technology, which is applied in the field of preparation of natural vegetable oil-based hydrophilic slow-rebound foam, can solve the problems of low open porosity, high temperature sensitivity of foam, sultry heat and the like, and achieves high air permeability, Environmentally friendly and low residue effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A. Mix polyols in proportion to form a polyol mixture

[0046] POLYOL 1: 50% POLYOL 2: 30%

[0047] POLYOL 3: 20%

[0048] B. Based on 100 parts of the above polyol mixture, 2 parts of glycerin, 2 parts of Momentive L3002 silicone oil, 1.5 parts of water, 2 parts of surfactant, 0.6 parts of triethylenediamine, bis(2-methylamino) Ethyl) ether, a mixture of retarded catalysts dissolved in the above polyol mixture, as A material.

[0049] C. According to the ratio that the isocyanate index is 75, take the urethane-modified MDI (material B) and react with the material A at 25° C. to prepare a natural vegetable oil-based hydrophilic polyurethane slow-rebound bulk foam.

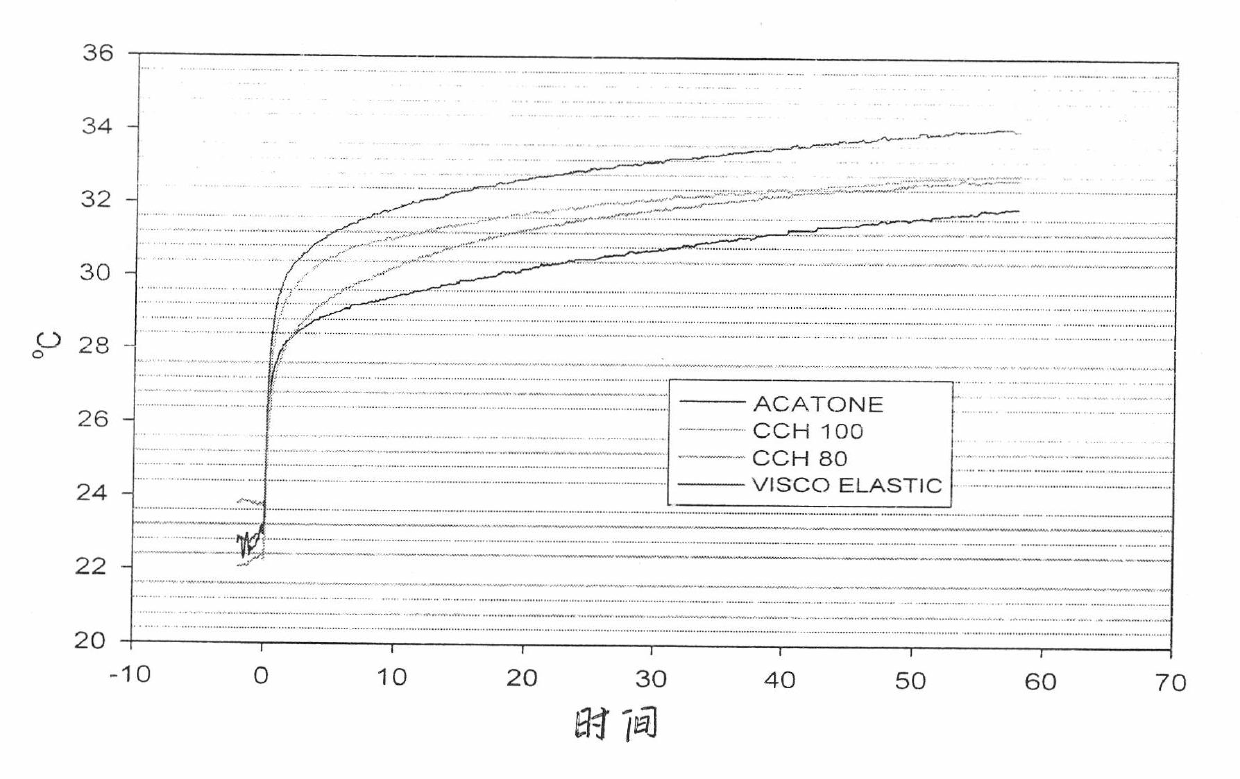

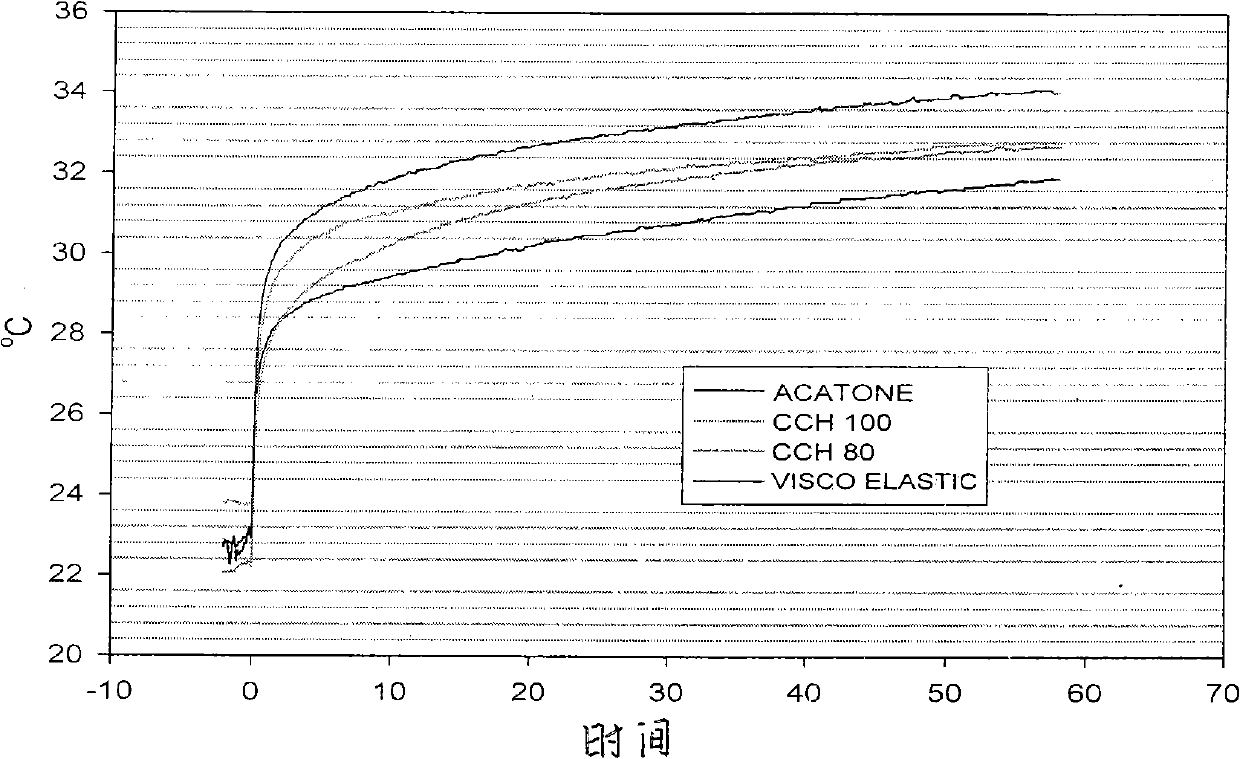

[0050] The natural vegetable oil-based hydrophilic slow-rebound foam produced by the invention has high air permeability, good heat dissipation and low temperature sensitivity.

Embodiment 2

[0052] A. Mix polyols in proportion to form a polyol mixture

[0053] POLYOL 1: 50% POLYOL 2: 30%

[0054] POLYOL 3: 20%

[0055] B. Based on 100 parts of the above polyol mixture, 2 parts of glycerin, 1.5 parts of Momentive L3002 silicone oil, 1.8 parts of water, 2 parts of surfactant, 0.8 parts of triethylenediamine, bis(2-methylaminoethyl) Base) ether, the mixture of delayed catalyst is dissolved in the above polyol mixture, as A material.

[0056]C. According to the ratio of isocyanate index to 75, take carbodiimide-modified MDI (material B), inject it into the mold after being uniform with material A at 25°C, and make natural vegetable oil-based hydrophilic polyurethane slow rebound after aging and demoulding Molded foam.

[0057] The natural vegetable oil-based hydrophilic slow-rebound foam produced by the invention has high air permeability, good heat dissipation and low temperature sensitivity.

Embodiment 3

[0059] A. Mix polyols in proportion to form a polyol mixture

[0060] POLYOL 1: 45% POLYOL 2: 30%

[0061] POLYOL 3: 5% POLYOL 4: 20%

[0062] B. Based on 100 parts of the above polyol mixture, 2 parts of glycerin, 2 parts of Momentive L3002 silicone oil, 1.5 parts of water, 2 parts of surfactant, 0.6 parts of triethylenediamine, bis(2-methylamino) Ethyl) ether, a mixture of retarded catalysts dissolved in the above polyol mixture, as A material.

[0063] C. According to the ratio of isocyanate index to 100, take urethane-modified MDI (material B) and react with material A at 25°C to prepare natural vegetable oil-based hydrophilic polyurethane slow-rebound bulk foam.

[0064] The natural vegetable oil-based hydrophilic slow-rebound foam produced by the invention has low residue, high air permeability, good heat dissipation and low temperature sensitivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com