Formula of putty for inner wall of building

A building and formula technology, applied in the direction of filling slurry, etc., can solve the problems of insufficient strength and hardness, poor stability, etc., and achieve the effects of saving usage, outstanding cost performance advantages, good stability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

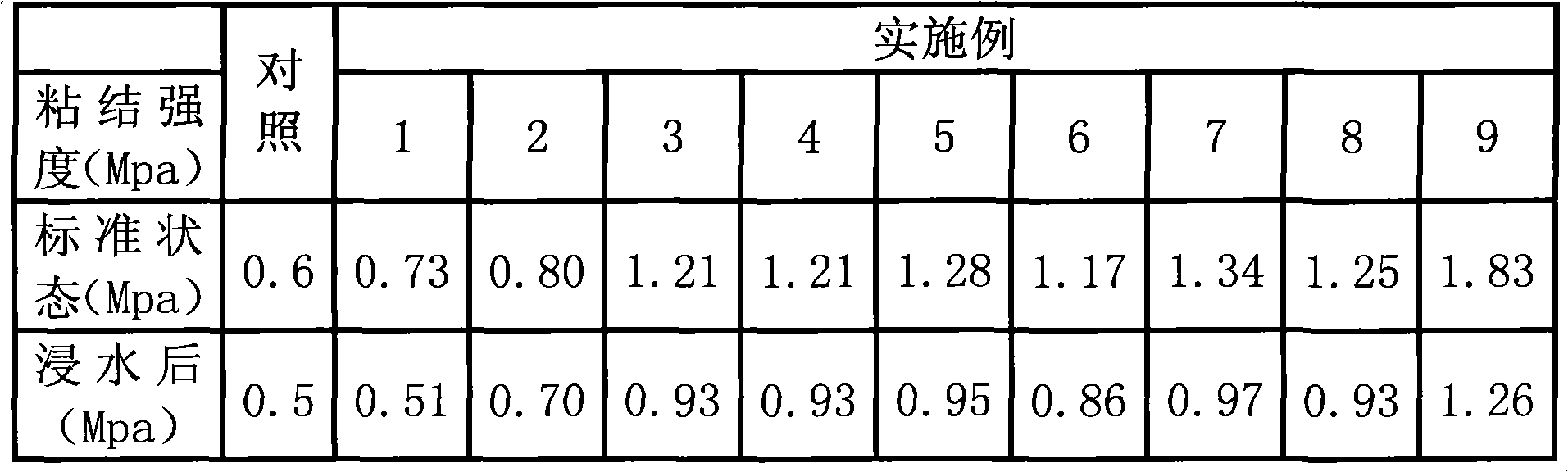

Examples

Embodiment 1

[0036] Wherein the desulfurized gypsum water-resistant and crack-resistant putty described in Examples 1-9 is calculated in parts by weight, and the weight ratios of each component are as follows, all of which are mixed by gravity-free double-flying knife mixing equipment.

[0037] Flue gas desulfurization gypsum 200 100 mesh quartz powder 360

[0038] 200 mesh quartz powder 150 400 mesh quartz powder 275

[0039] HPMC70000 3 Sodium bentonite 5

[0040] Retardan P 0.2 ARBOCEL ZZC500 2

[0041] VINNAPAS5044N 5

Embodiment 2

[0043] Flue gas desulfurization gypsum 250 100 mesh quartz powder 335

[0044] 200 mesh quartz powder 150 400 mesh quartz powder 250

[0045] HPMC70000 3 Sodium bentonite 5

[0046] Retardan P 0.25 ARBOCEL ZZC500 2

[0047] VINNAPAS5044N 5

Embodiment 3

[0049] Flue gas desulfurization gypsum 300 100 mesh quartz powder 350

[0050] 200 mesh quartz powder 85 400 mesh quartz powder 250

[0051] HPMC70000 3 Sodium bentonite 5

[0052] Retardan P 0.3 ARBOCEL ZZC500 2

[0053] VINNAPAS5044N 5

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com