Method for preparing cobalt-based Fischer-Tropsch synthesis catalyst

A technology for Tropsch synthesis and catalyst, which is applied in the field of preparation of cobalt-based Fischer-Tropsch synthesis catalyst, can solve problems such as complicated preparation process, and achieve the effects of simple preparation, mature process technology and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Weigh commercially available silica gel (pore volume is 1.06ml / g, specific surface area is 386.81m 2 / g, the following examples all use the silica gel) 30g, distilled water is added dropwise to initial moistening, the volume of consumed water is 48ml, 48ml concentration is 20% pyridine solution, add in silica gel at 50 ℃, process 10 hours. Dry at 60°C for 24 hours, then bake at 280°C for 15 hours. Based on the final catalyst cobalt content of 5 wt%, cobalt nitrate was weighed and dissolved in 48ml of water, added to the surface-modified silica gel carrier for impregnation, aged for 3 hours, dried at 80°C for 8 hours, and calcined at 350°C for 4 hours. The resulting catalyst was designated as C-1.

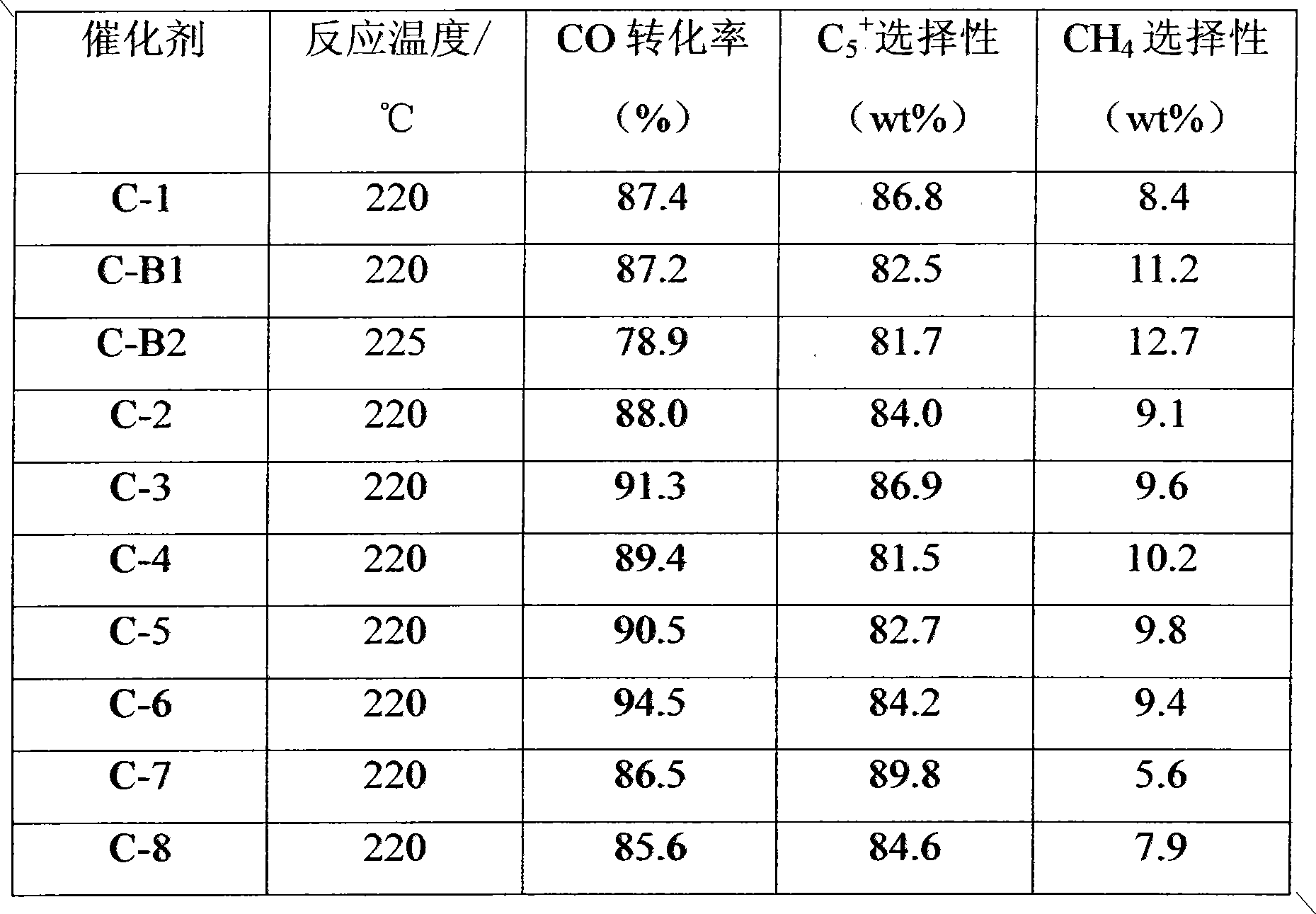

[0022] Catalyst evaluation test In a high-pressure continuous stirred tank reactor, paraffin was used as a solvent, and pure hydrogen was reduced at 350° C. for 12 hours, and the pressure was 1.0 MPa. After cooling down, the synthesis gas is switched to react. The reaction...

example 2

[0024] Weigh 30g of commercially available silica gel, add distilled water dropwise until initial moistening, the volume of consumed water is 48ml, add 48ml of 15% diethanolamine solution into the silica gel at 80°C, and stir. Treat for 30 hours and dry at 90°C for 16 hours. Based on the final cobalt content of the catalyst being 15 wt%, cobalt nitrate was weighed and dissolved in 48ml of water, added to the surface-modified silica gel carrier for impregnation, aged for 3 hours, dried at 80°C for 8 hours, and calcined at 350°C for 4 hours. The resulting catalyst is designated C-2. The experimental conditions for catalyst activity evaluation are the same as in Example 1. The results of the Fischer-Tropsch synthesis reaction over the C-2 catalyst are shown in Table 1.

example 3

[0026] Weigh 30g of commercially available silica gel, add distilled water dropwise until initial moistening, the volume of consumed water is 48ml, add 48ml of 5% ethanolamine solution to the silica gel at 95°C, stir for 100 hours, and dry at 100°C for 8 hours. Based on the final cobalt content of the catalyst being 15 wt%, cobalt nitrate was weighed and dissolved in 48ml of water, added to the surface-modified silica gel carrier for impregnation, aged for 3 hours, dried at 80°C for 8 hours, and calcined at 350°C for 4 hours. The resulting catalyst was designated C-3. The experimental conditions for catalyst activity evaluation are the same as in Example 1. Table 1 shows the results of the Fischer-Tropsch synthesis reaction over the C-3 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com