Multiple-reaction cavity metallorganic chemical vapor deposition equipment

A technology of chemical vapor deposition and metal organics, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of long waiting time, high cost, and inability to carry out multiple processes at the same time, so as to save processing time, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

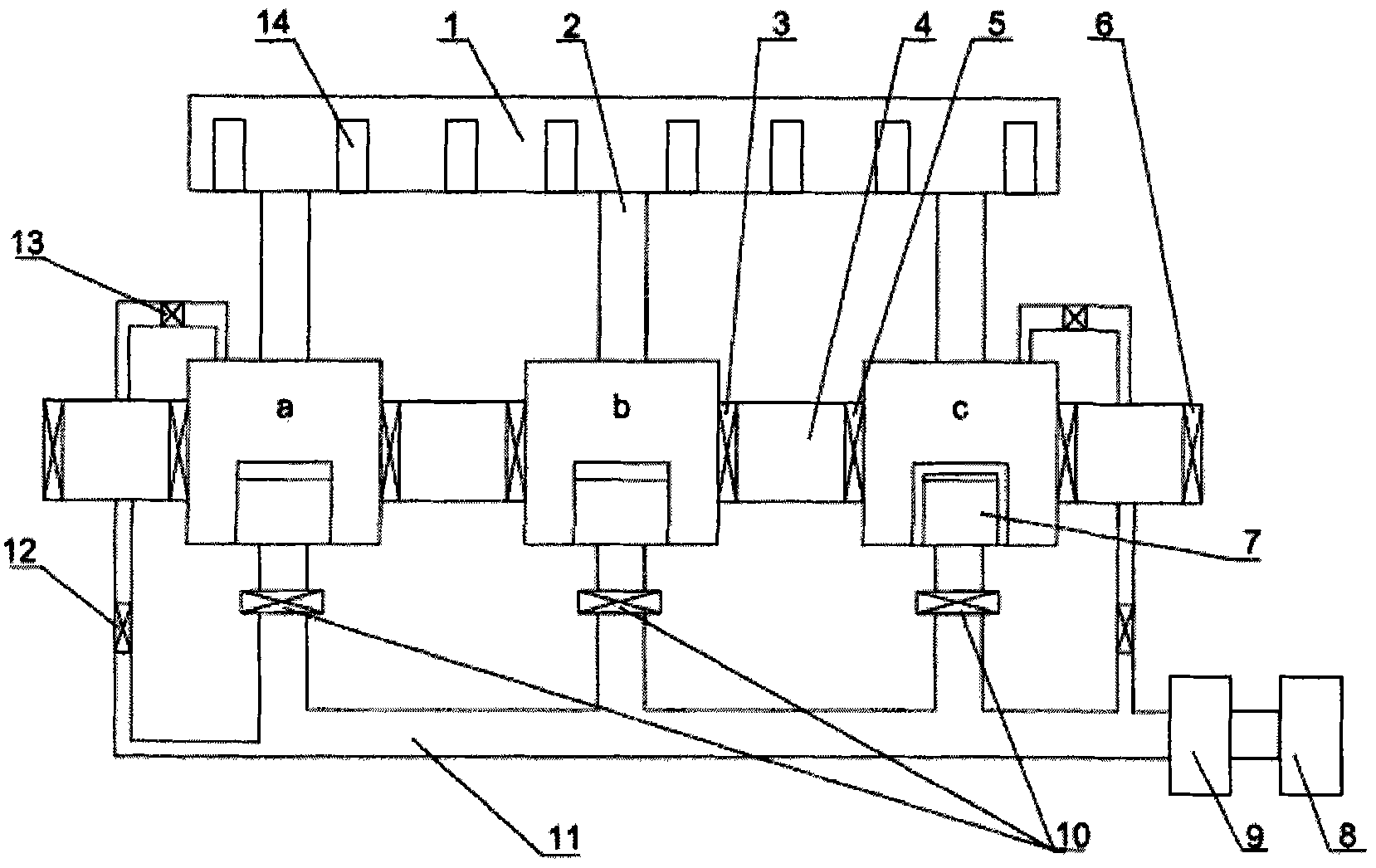

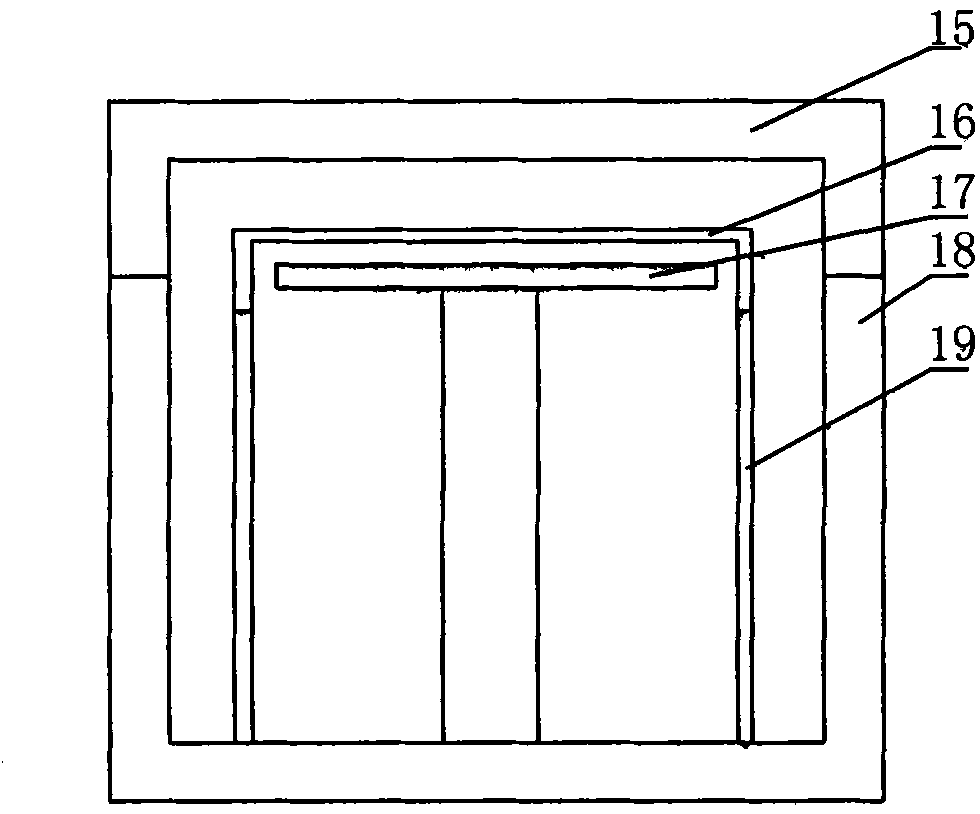

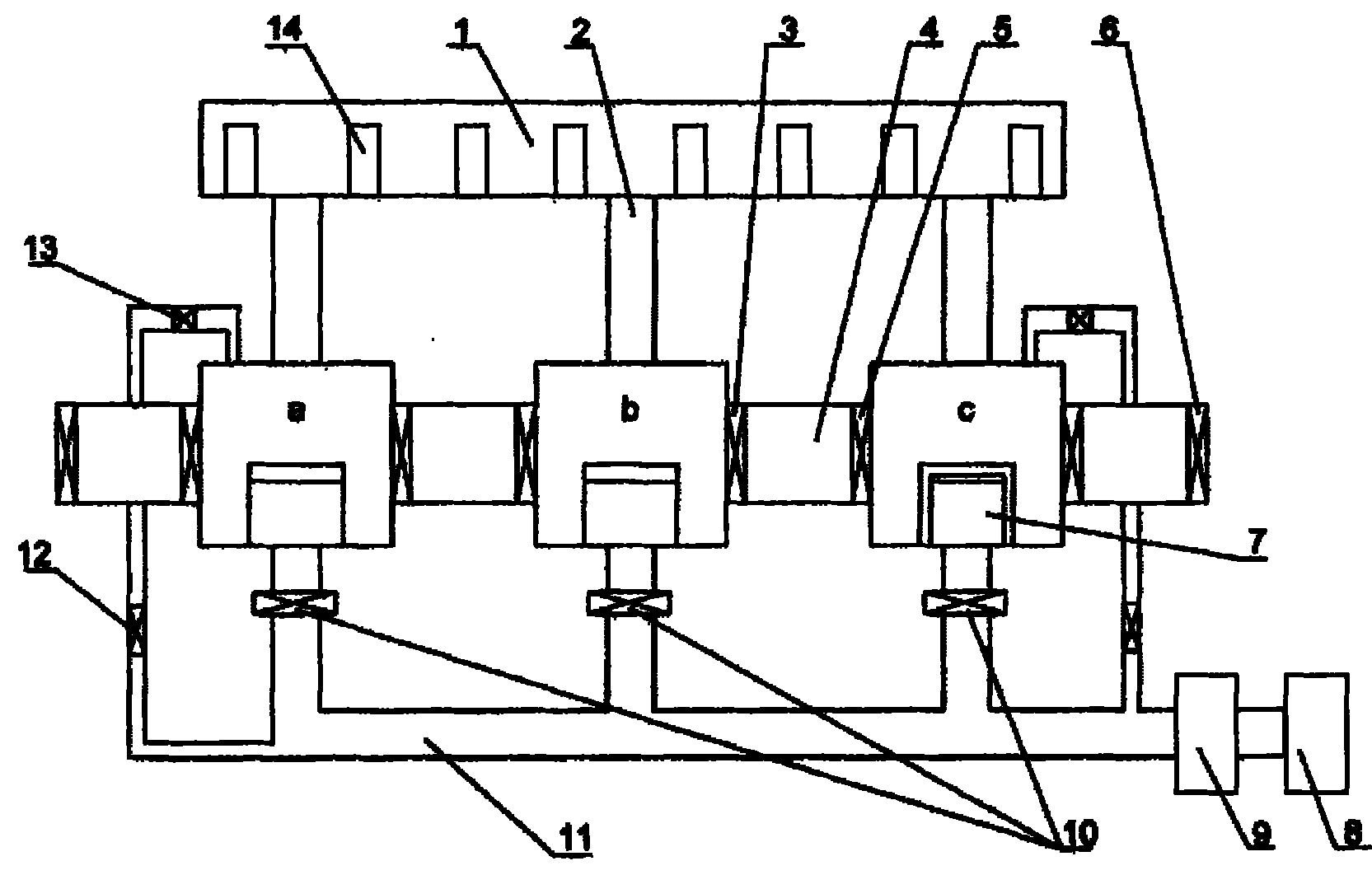

[0011] see figure 1 , The device of the present invention has two or more reaction chambers 7, and each reaction chamber 7 is connected to each other by a gas delivery system. The device of this embodiment has three reaction chambers 7. Three reaction chambers 7 are respectively installed in glove box a, glove box b, and glove box c. composition. The upper cover 15 of the reaction chamber and the lower cover 18 of the reaction chamber are detachable, so that the manipulator can transfer the graphite disk 16 from the reaction chamber 7, and the fairing 19 is a quartz structure, which can play a role of heat preservation, thereby improving the heat utilization rate, see figure 2 . The tail gas treatment system consists of a control valve 10, a tail gas pipeline 11, a vacuum pump 9, and a tail gas treatment device 8. The source gas 1 is carried from the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com