Piston four stroke engine

A four-stroke engine, piston type technology, applied in engine components, engine control, machine/engine, etc., can solve the problems of short valve spark ignition duration, low engine efficiency, large fuel loss, etc. The effect of interference, exhaustion, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

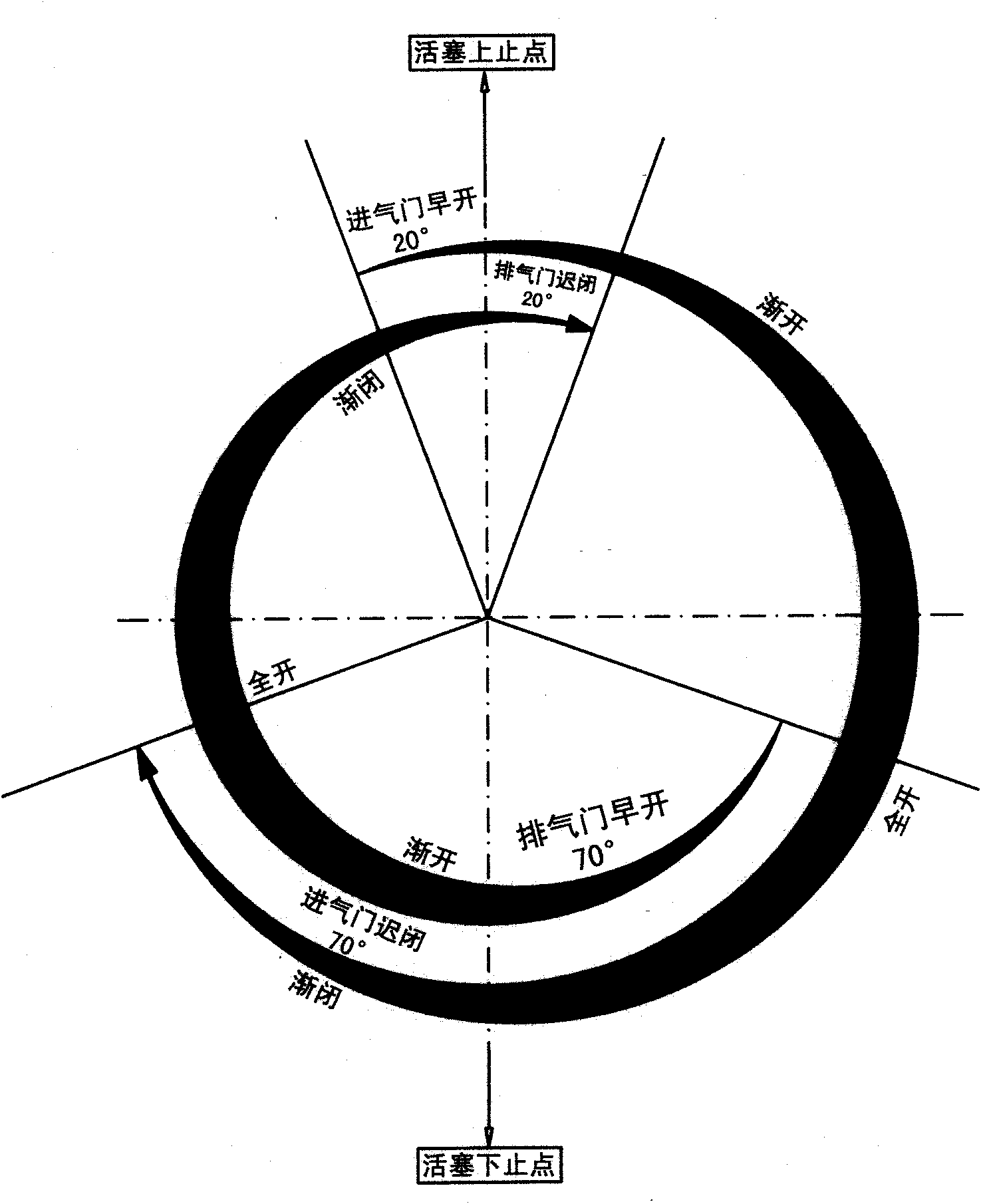

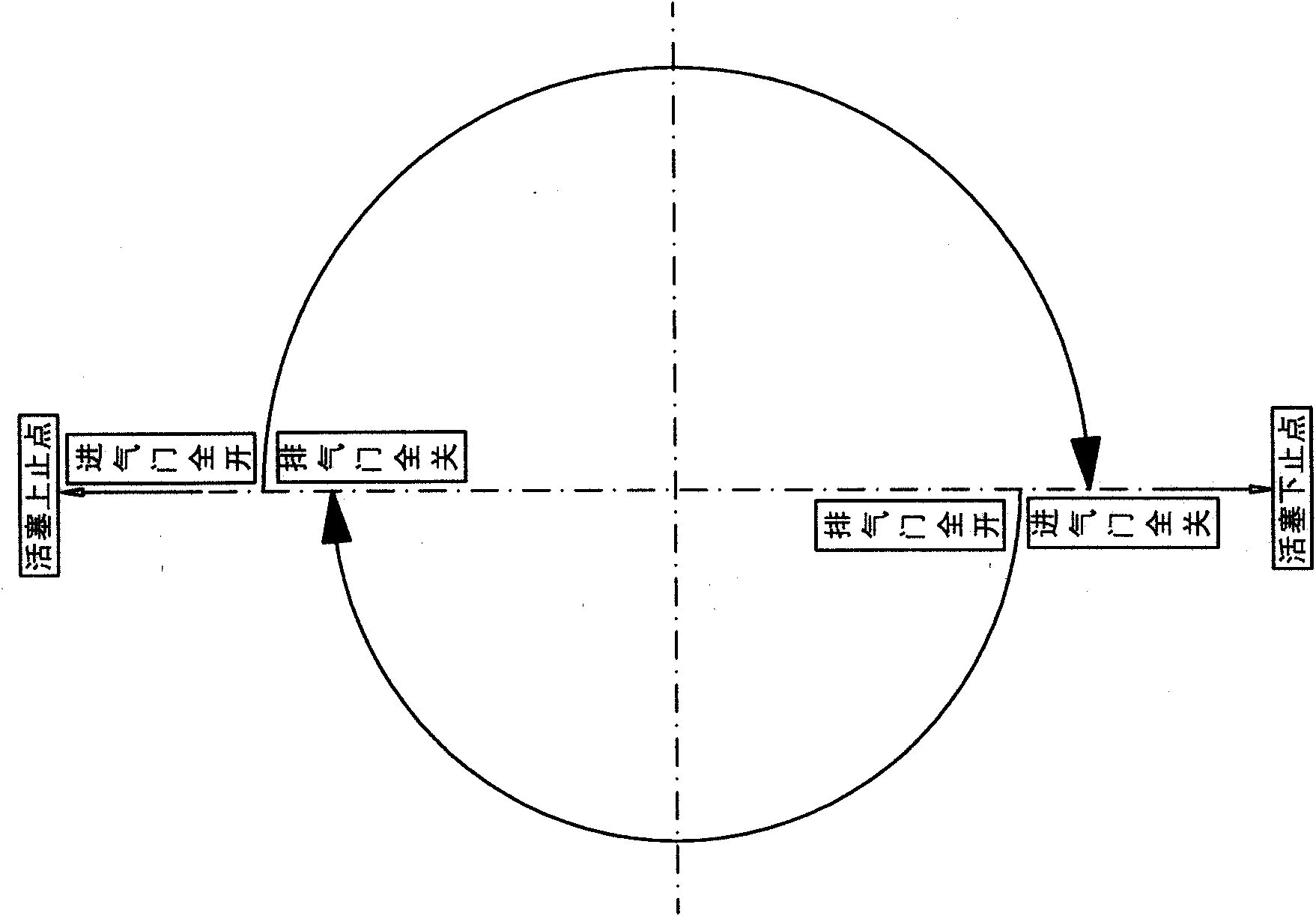

Method used

Image

Examples

Embodiment Construction

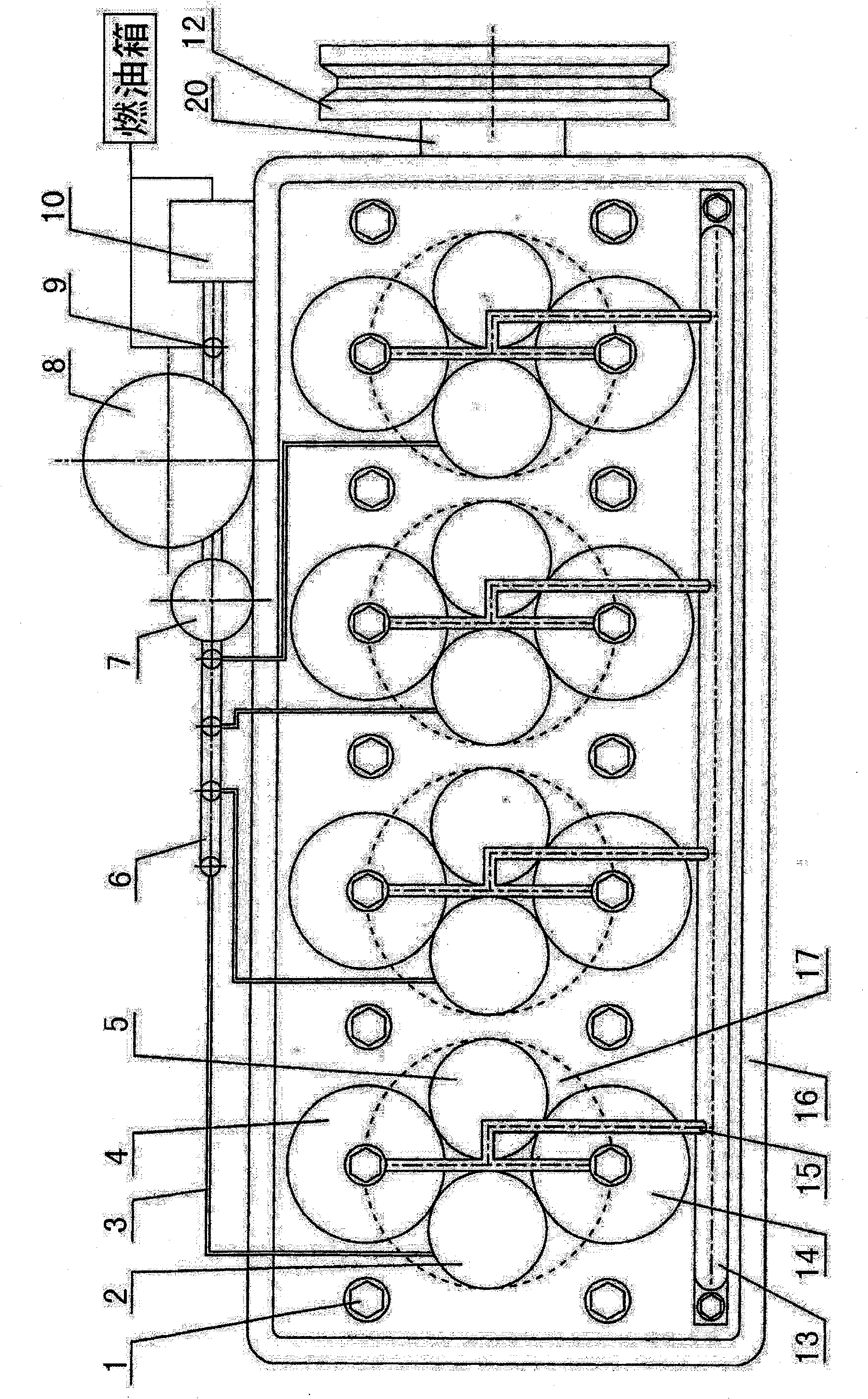

[0030] The present invention will be described in detail below by taking a four-cylinder engine as an example.

[0031] see image 3 and Figure 4 , The present invention includes a valve train, an ignition device and a fuel injector 2. The positions of the cylinder head 16 corresponding to the four cylinders (dotted circle in the figure) are respectively installed with the fuel injector 2 and the ignition coil 5 of the ignition device.

[0032] The fuel inlet of the fuel injector 2 is connected to the outlet of a constant pressure device 8 through a branch line 3 and a fuel branch joint 6 , and a high pressure shut-off valve 7 is installed between the fuel branch joint 6 and the constant pressure device 8 . The inlet of the constant pressure device 8 is connected with the outlet of the check valve R of the oil inlet joint 9 and the inlet end of the return joint 19, and the outlet end of the return joint 19 is connected with the fuel tank; the check valve R is only when the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com