YBCO thick film resistance paste based on stainless steel base board and preparation method thereof

A technology of thick film resistors and stainless steel, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, heating element materials, etc., can solve the impact of performance stability and service life, limit the promotion and use of thick film resistor paste, silver ions Easy to migrate and other issues, to achieve good compatibility, excellent conductivity, and firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The numerical values of each component involved in this embodiment are as follows, and its unit is determined by the previous implementation mode part:

[0030] Solid phase composition: organic vehicle = 60: 40;

[0031] YBCO ceramic powder: glass powder = 60: 40;

[0032] The molar ratio of each component of YBCO ceramic powder is Y 2 o 3 :BaO:CuO=1:1:8;

[0033] The weight percent of glass raw material is:

[0034] SiO 2 : 30.21%, H 3 BO 3 : 25.86%, NaNO 3 : 43.93%;

[0035] The organic vehicle contains the following components:

[0036] Terpineol: 50%, Ethylcellulose: 20%, Tributyl Citrate: 10%,

[0037] 1,4-Butyrolactone: 10%, Lecithin: 10%.

Embodiment 2

[0039] The numerical values of each component involved in this embodiment are as follows, and its unit is determined by the previous implementation mode part:

[0040] Solid phase composition: organic vehicle = 85:15;

[0041] YBCO ceramic powder: glass powder = 99.9: 0.1;

[0042] The molar ratio of each component of YBCO ceramic powder is Y 2 o 3 :BaO:CuO=2:2:6;

[0043] The weight percent of glass raw material is:

[0044] SiO 2 : 19.77%, H 3 BO 3 : 28.85%, NaNO 3 : 23.63%, Al 2 o 3 : 2.97%, Ba(NO 3 ) 2 : 9.07%, LiNO 3 : 13.73%, ZnO: 1.98%;

[0045] The organic vehicle contains the following components:

[0046] Terpineol: 90%, Ethylcellulose: 1%, Nitrocellulose: 9%.

Embodiment 3

[0048] This embodiment provides a preparation method for 1Cr17 (430#) series stainless steel substrate thick film resistor slurry, as follows:

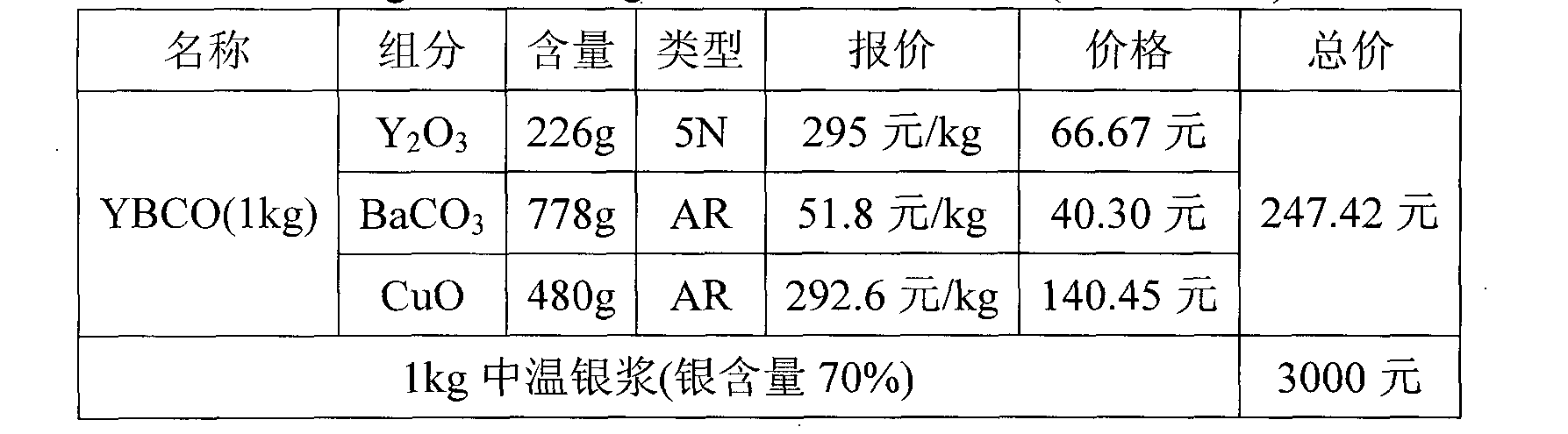

[0049] 1. Formula of YBCO ceramic powder: Y according to the molar ratio of active ingredients 2 o 3 :BaO:CuO=1:4:6 ratio raw material Y 2 o 3 , BaCO 3 and CuO;

[0050] 2. Set Y 2 o 3 , BaCO 3 Mix with CuO evenly, wet ball mill for 24 hours, and dry;

[0051] 3. Put it into a resistance furnace for pre-firing, the pre-firing temperature is 900°C, and keep it warm for 3 hours;

[0052] 4. Wet ball mill the pre-burned powder again for 24 hours and dry;

[0053] 5. Put it into a resistance furnace for sintering, the sintering temperature is 920°C, and keep it warm for 3 hours;

[0054] 6. Glass formula: SiO 2 : 30.21%, H 3 BO 3 : 25.86%, NaNO 3 : 43.93%;

[0055] 7. Glass melting process: 1100°C, heat preservation for 2 hours, water quenching;

[0056] 8. Put the obtained glass slag into a ball mill for wet ball milling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com