Active matrix/organic light emitting display and manufacturing method thereof

A light-emitting display and active matrix technology, applied in the field of active-matrix organic light-emitting display and its manufacturing, can solve the problems that cannot fully meet the application requirements of AMOLED, it is difficult to drive TFT, etc., and achieve overall performance and high carrier migration. rate, good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

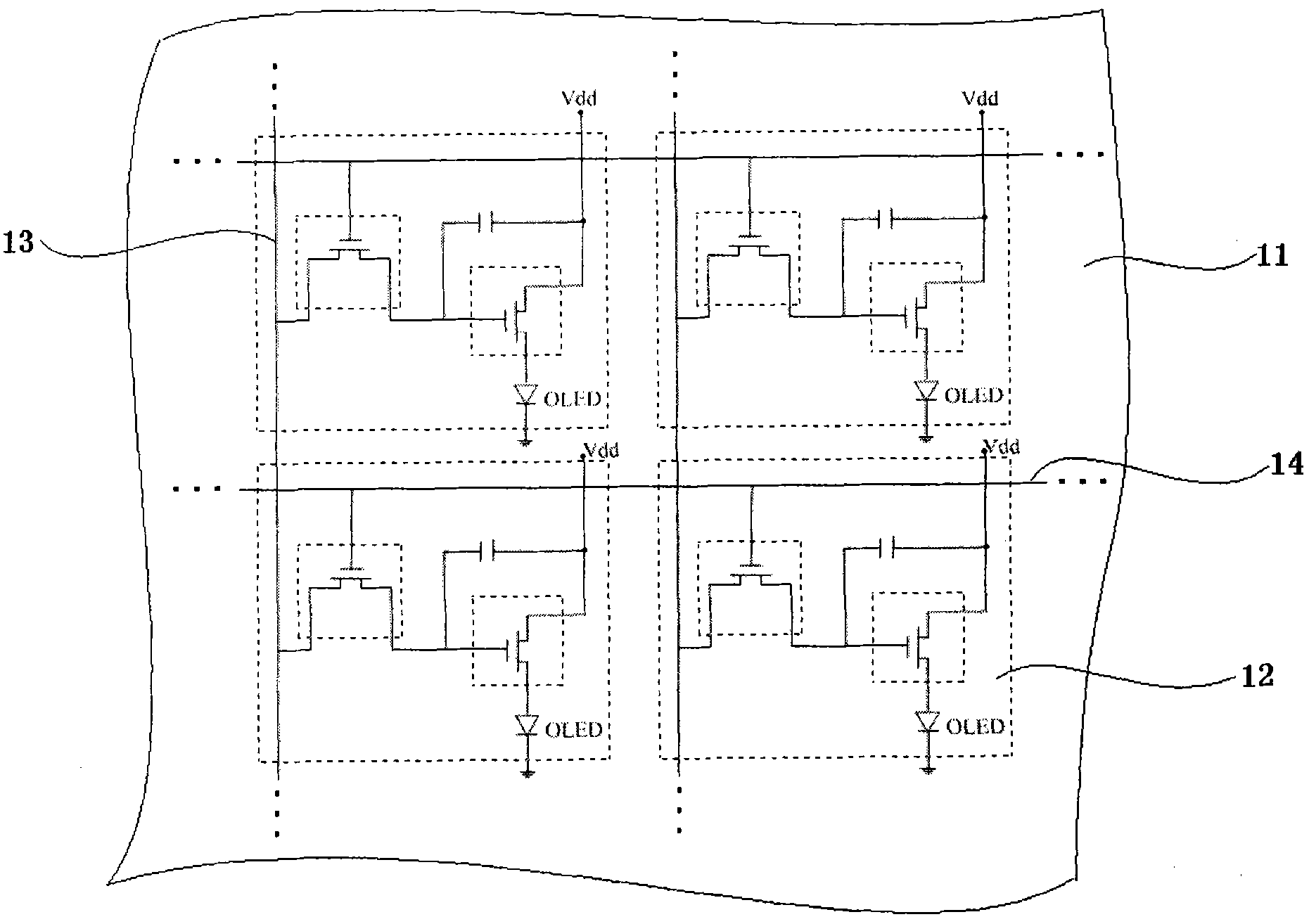

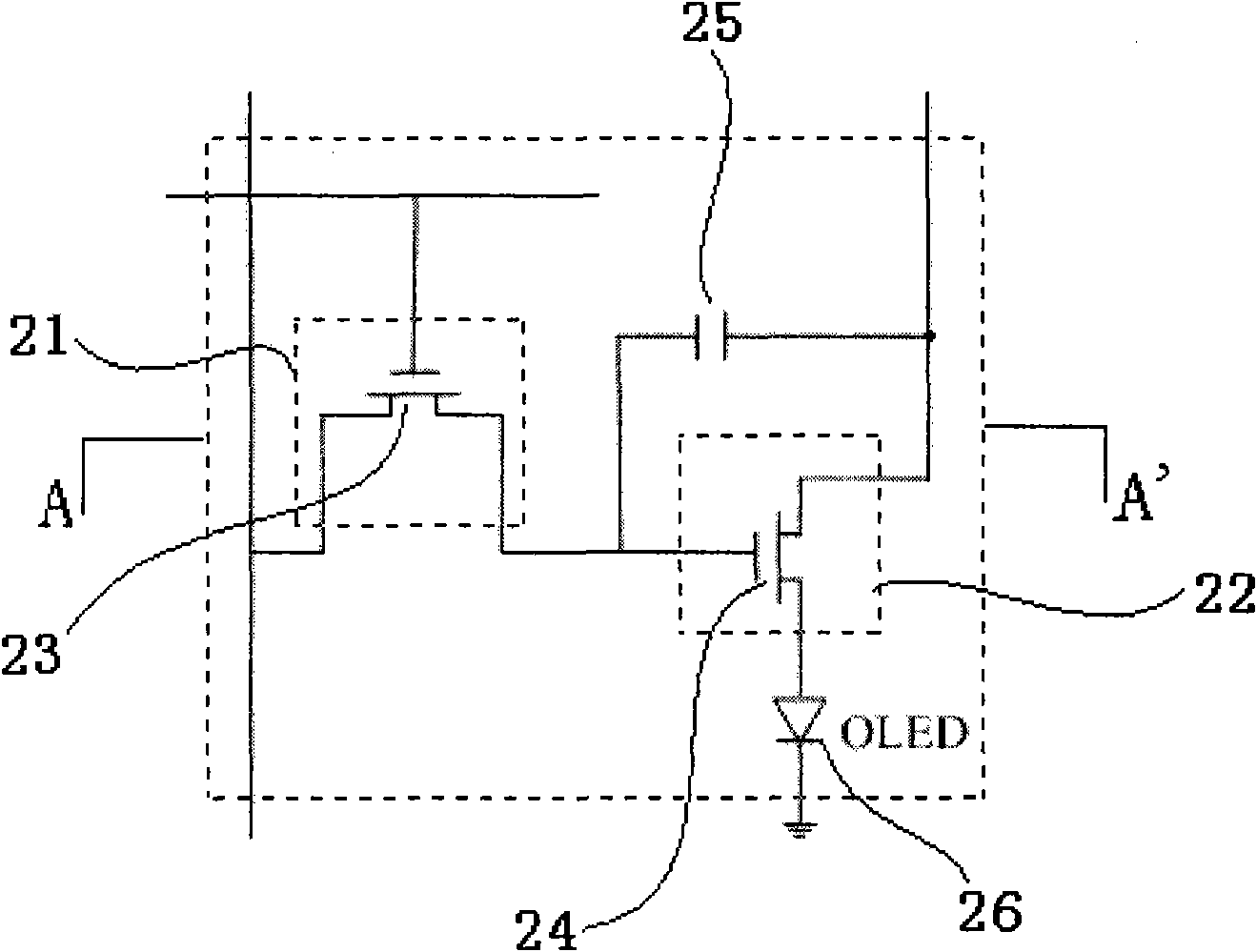

[0030] figure 1 It is a schematic diagram of a local circuit structure of an array substrate of an active matrix organic light-emitting display. As shown in the figure, the array substrate includes a glass substrate 11, and a plurality of pixels 12 arranged on the substrate are arranged in a matrix and arranged in parallel between the pixels A plurality of data lines 13 and a plurality of scan lines 14 arranged between the pixels and perpendicular to the data lines are arranged in parallel. figure 2 for figure 1 The schematic diagram of the enlarged structure of the pixel 12, as shown in the figure, the pixel 12 has a switching area 21 and a driving area 22 in the pixel area, the switching area 21 has a switching thin film transistor 23, and the driving area 22 It has a driving thin film transistor 24 , and also includes a storage capacitor 25 and an organic light emitting device 26 . The carrier mobility of the driving thin film transistor 24 is about 25 cm 2 / Vs, the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com