Crystallization method of clindamycin phosphate

A technology of clindamycin phosphate and crystallization, applied in the production field of clindamycin phosphate, can solve the problems of low crystallization yield and the like, and achieve the effects of high crystallization yield, improved purity, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

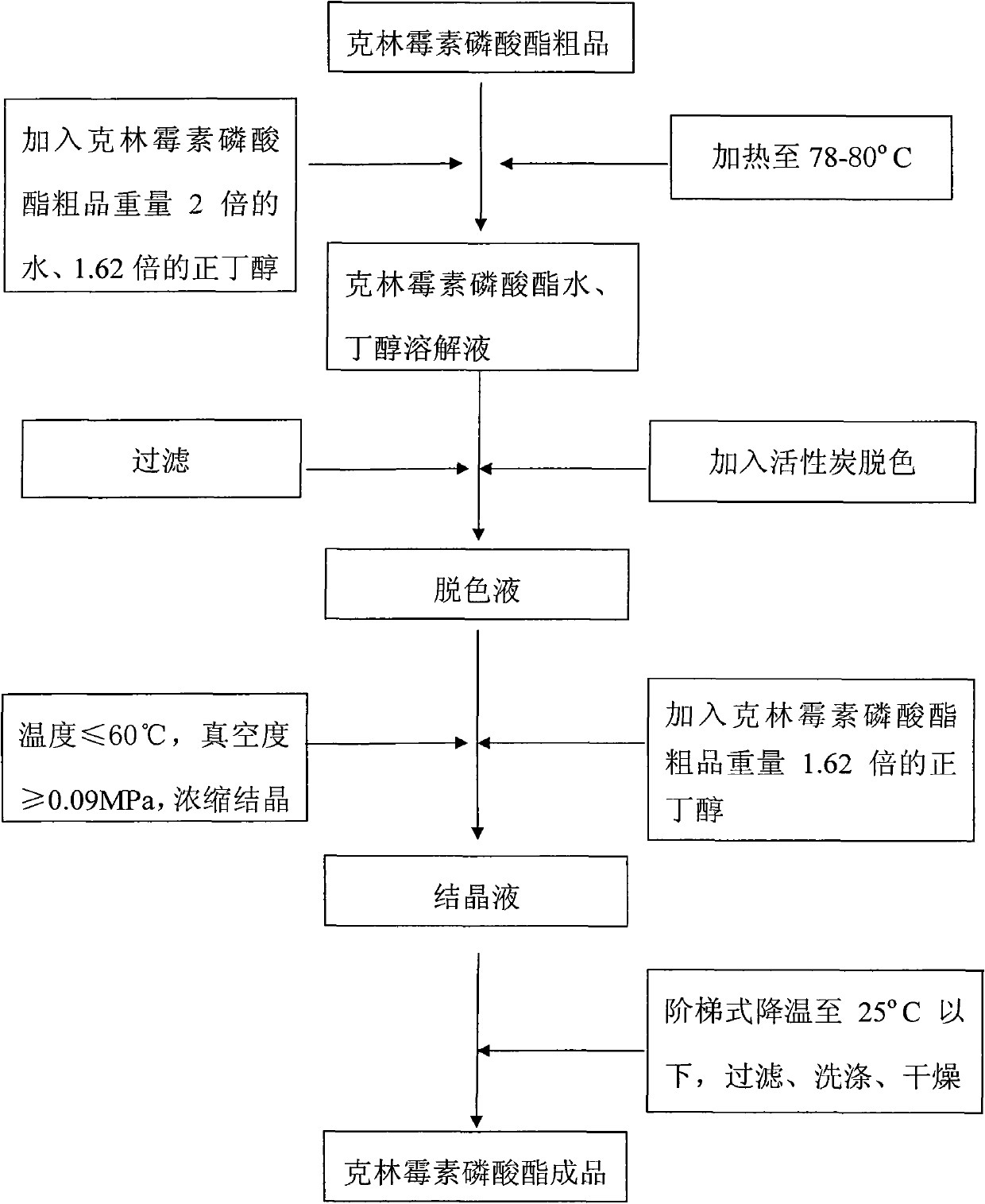

Image

Examples

Embodiment 1

[0021] (1), in a 500ml spherical decolorizing tank, drop about 40g of clindamycin phosphate coarse powder (clindamycin hydrochloride obtained through esterification, hydrolysis, adsorption, and crude crystallization), add 64.8g of n-butanol and 80g of purified Water, stir and heat up to 78-80°C under water bath conditions, and keep the temperature constant for about 60 minutes;

[0022] (2), after the clindamycin phosphate coarse powder is fully dissolved, add 2g of activated carbon for decolorization, and filter while hot to remove insoluble impurities;

[0023] (3), the decolorizing liquid is pressed into a 500ml spherical crystallization tank through a fine filter, 64.8g of n-butanol is added, and when the clarified hot saturated solution of the gained is cooled to 60°C, it is vacuum concentrated, and the vacuum degree is greater than or equal to 0.09MPa. When the crystals are precipitated, stop the concentration, stir the solution at a speed of 100r / min, and keep the tempe...

Embodiment 2

[0026] (1), in a 1000ml spherical decolorization tank, drop about 80g of clindamycin phosphate coarse powder (clindamycin hydrochloride obtained through esterification, hydrolysis, adsorption, and crude crystallization), add 129.6g of n-butanol and 160g of purified Water, stir and heat up to 70-80°C in a water bath, and keep the temperature constant for about 60 minutes;

[0027] (2), after the clindamycin phosphate coarse powder is fully dissolved, add 4g of activated carbon for decolorization, and filter while hot to remove insoluble impurities;

[0028] (3) Press the decolorizing solution into a 1000ml spherical crystallization tank through a fine filter, add 129.6g of n-butanol, and when the resulting clear hot saturated solution is cooled to 60°C, slowly vacuum it to concentrate, when crystals are precipitated , stop the concentration, stir the solution at a speed of 100r / min, and keep the temperature at this temperature for 60min;

[0029] (4), then adjust the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com