Passive anode of direct methanol fuel cell based on MEMS (Micro-electromechanical Systems) and manufacturing method thereof

A methanol fuel cell, passive technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult packaging, manufacturing, complex structure, etc., and achieve the effects of good compatibility, simple manufacturing process, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

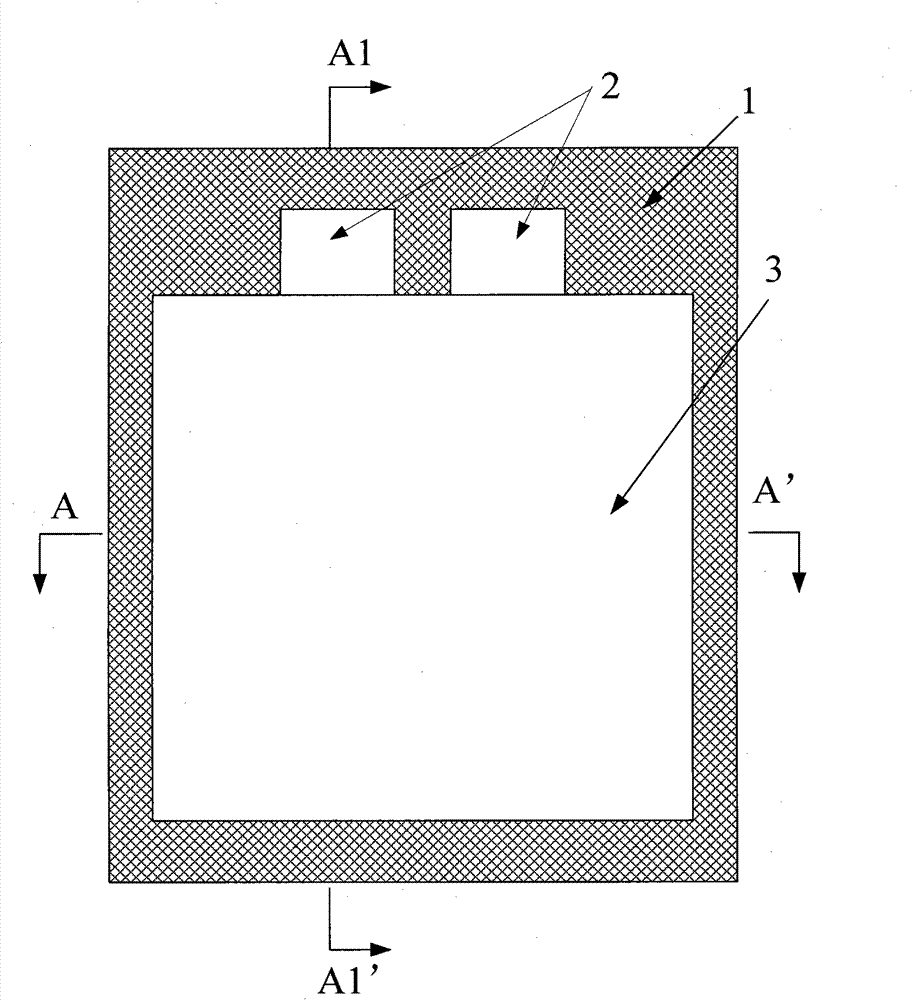

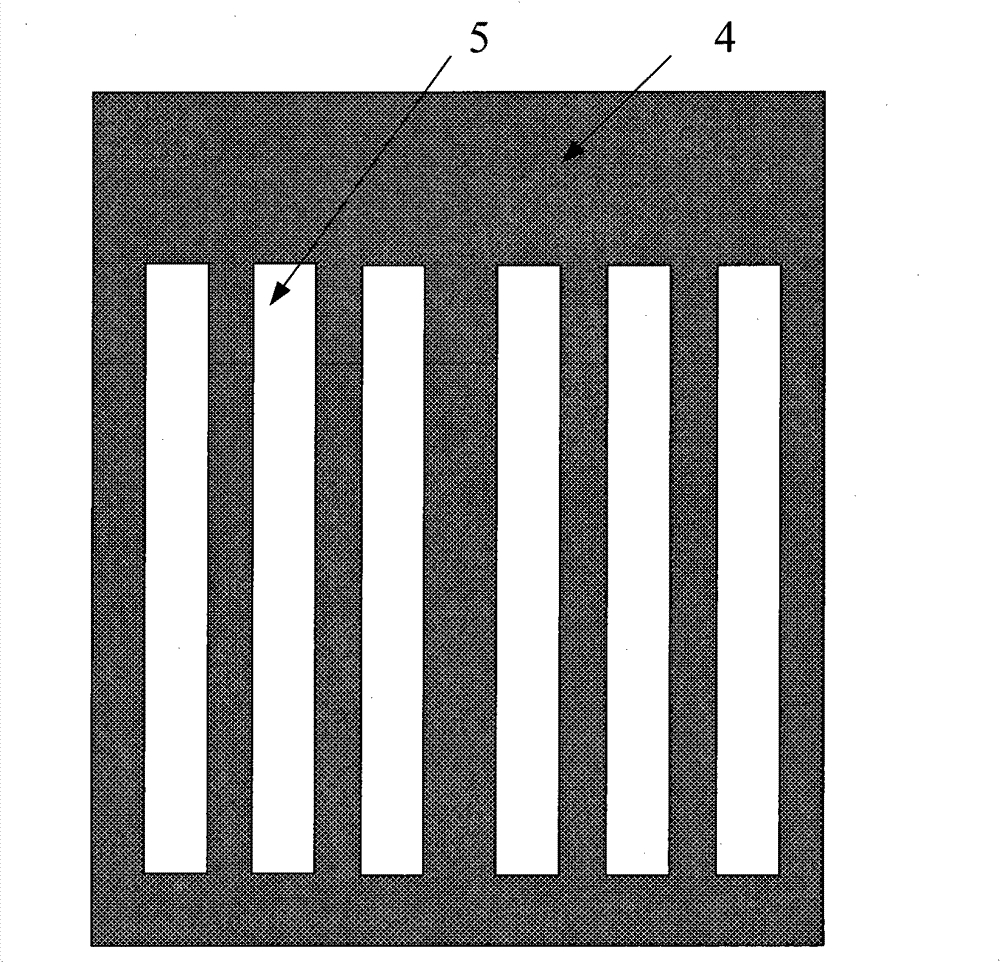

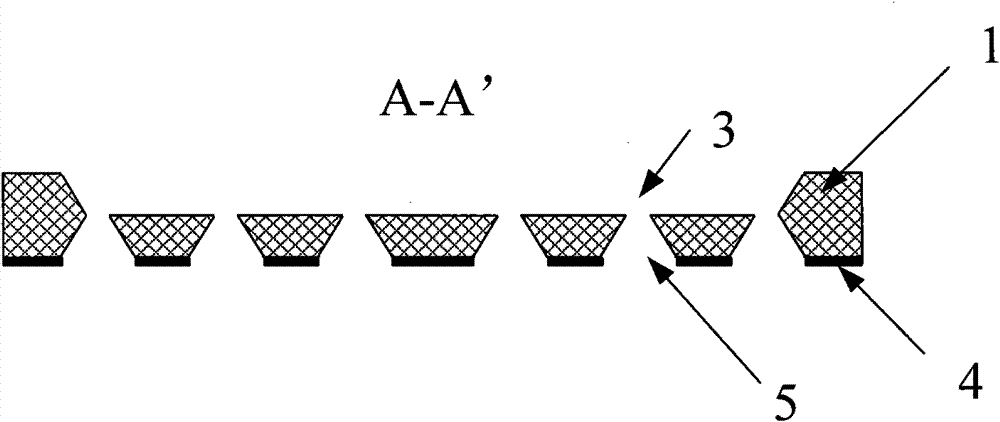

[0030] The present invention provides a passive anode structure of a direct methanol fuel cell based on MEMS technology and a manufacturing method thereof. The present invention will be further described below through the description of drawings and specific implementation methods.

[0031] Such as Figure 1(a)-Figure 1(d) and Figure 2(a)-Figure 2(d) As shown, the anode structure includes two silicon plates, a methanol storage plate 6 and a water storage plate 1, which are respectively used to store methanol and water; the front side of the methanol storage plate 6 is a methanol storage chamber 7, and the back side is provided with Methanol output hole 9, a layer of hydrophobized porous silicon membrane 10 is set between the methanol storage cavity 7 and the methanol output hole 9, to transmit methanol and inhibit the reverse transmission of water; the front of the water storage plate 1 is a water storage Cavity 3, the back is a plurality of elongated channels 5, and a layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com