Vector control device for induction motor

A technology of induction motor and vector control, applied in motor generator control, electronic commutation motor control, vector control system and other directions, can solve the problems of large rotation speed observation error, system instability, and inability to guarantee algorithm stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

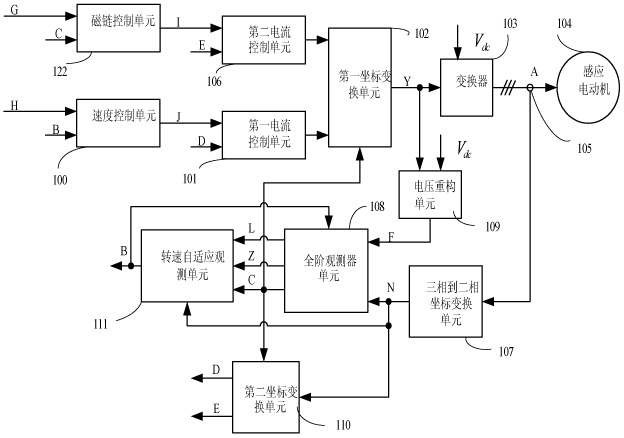

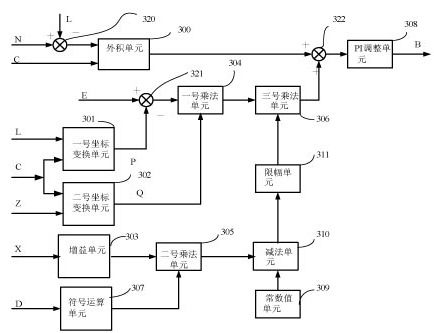

[0012] Specific implementation mode one: the following combination Figure 1 to Figure 3 This embodiment will be specifically described. This embodiment includes a current sensor 105, a converter 103, a first coordinate transformation unit 102, a second coordinate transformation unit 110, a three-phase to two-phase coordinate transformation unit 107, a voltage reconstruction unit 109, a first current control unit 101, a second Two current control unit 106, speed control unit 100, flux linkage control unit 122, full-order observer unit 108 and rotational speed adaptive observation unit 111,

[0013] After the stator current A of the induction motor 104 is sampled by the current sensor 105, it is sent to the three-phase to two-phase coordinate transformation unit 107 for coordinate transformation of the α-β stationary coordinate axis system. The second coordinate transformation unit 110 is based on the full-order observer unit 108 The observed angle of the observed value C of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com