Process for producing color conversion filter

A manufacturing method and technology of color filters, applied in the fields of optical filters, semiconductor/solid-state device manufacturing, optics, etc., can solve problems such as cumbersome procedures and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

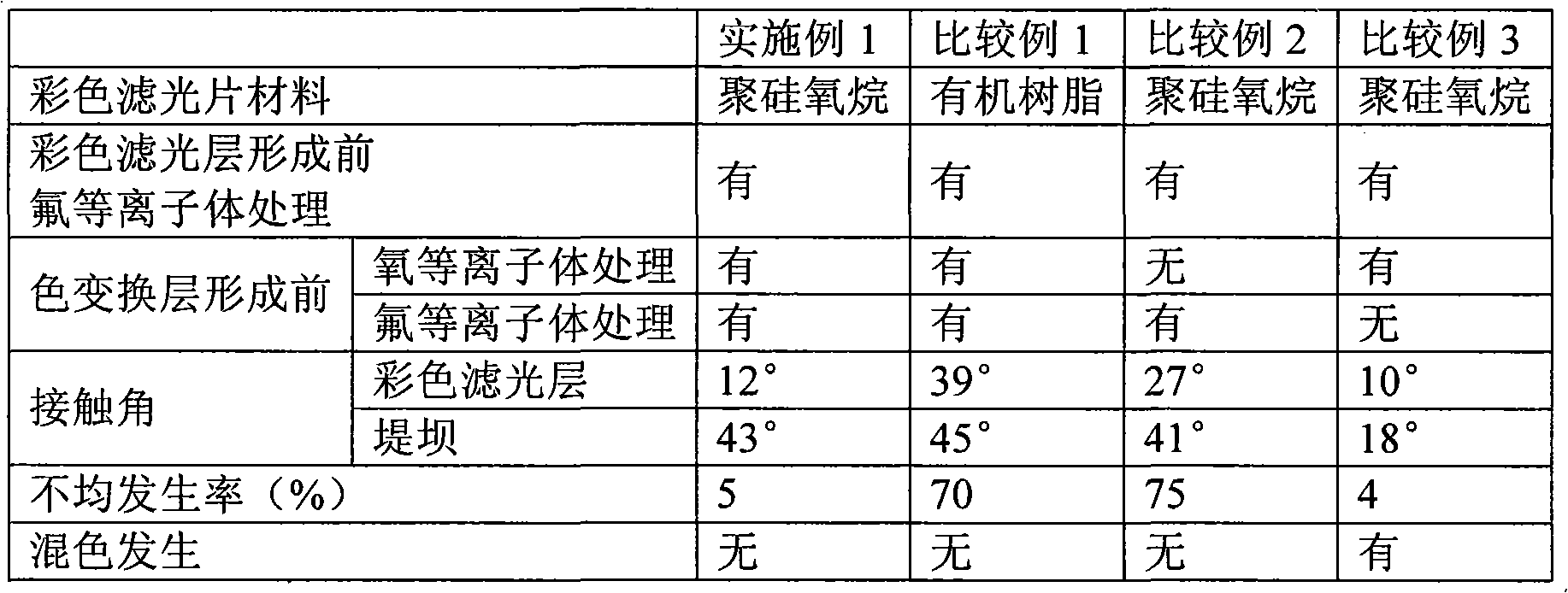

Examples

Embodiment 1

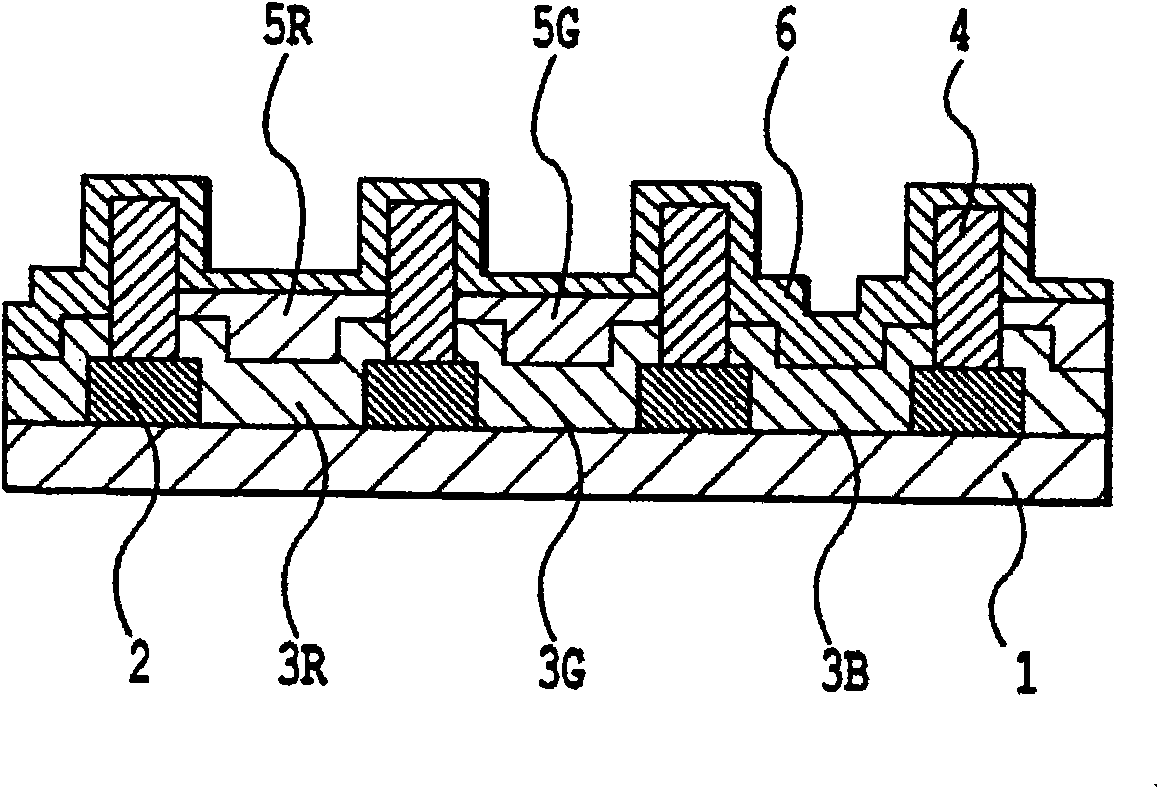

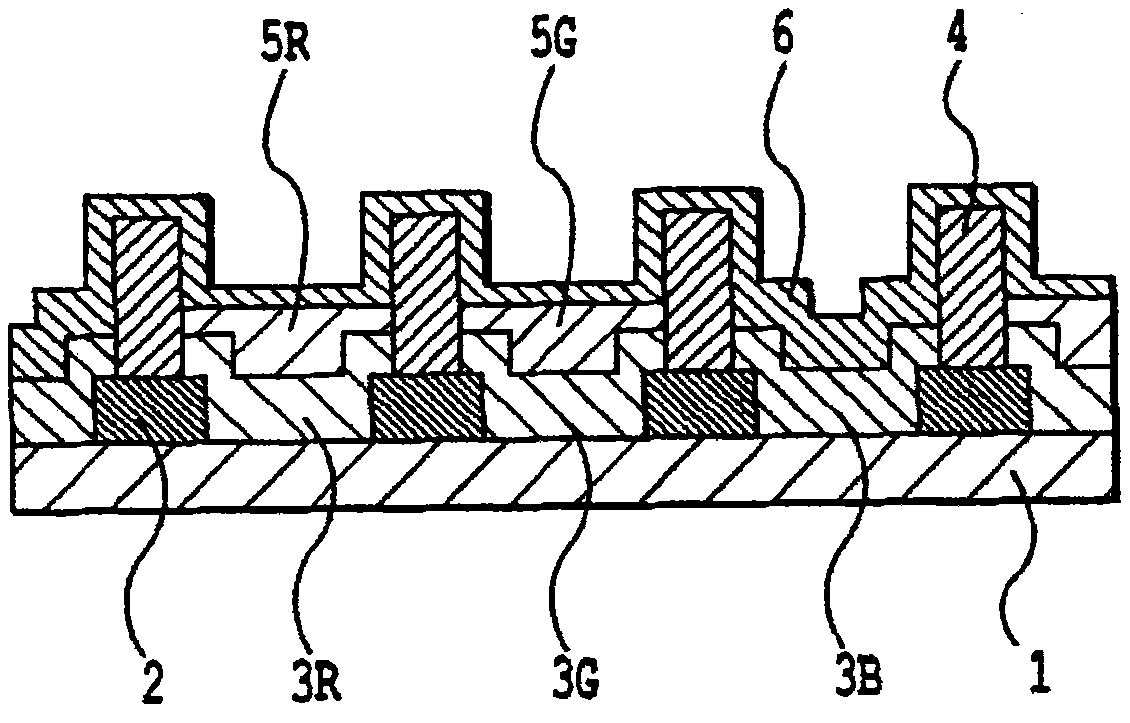

[0068] A color mosaic (color mosaic) CK-7001 (available from Fujifilm Co., Ltd.) is coated on a transparent substrate 1 (1737 glass produced by Corning Co., Ltd.), and a black matrix 2 having a plurality of rectangular openings is formed by photolithography. . Black matrix 2 has a film thickness of 1 μm. Each of the rectangular openings (corresponding to sub-pixels) has a length of 300 μm×a width of 100 μm, and the interval between adjacent rectangular openings is 30 μm in the length and 10 μm in the width.

[0069] Next, apply photocurable acrylate resin (V259PA / P5, produced by Nippon Steel Chemical Co., Ltd.), and use photolithography to form a pattern. On the black matrix 2, a bank 4 consisting of a plurality of strips extending in the longitudinal direction is formed. , the strip-shaped portions constituting the embankment 4 have a width of 10 μm and a height of 5 μm, respectively.

[0070] Next, at atmospheric pressure, in the ATOMFLO device (Surfx Technologies LLC prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com