Method for extracting fatty compounds from bee pollen

A technology of fatty compounds and bee pollen, applied in organic chemical methods, purification/separation/stabilization of organic compounds, chemical instruments and methods, etc., can solve problems such as low extraction efficiency, large carbon dioxide consumption, and increased device loss. To achieve the effect of shortening extraction time, saving dosage and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

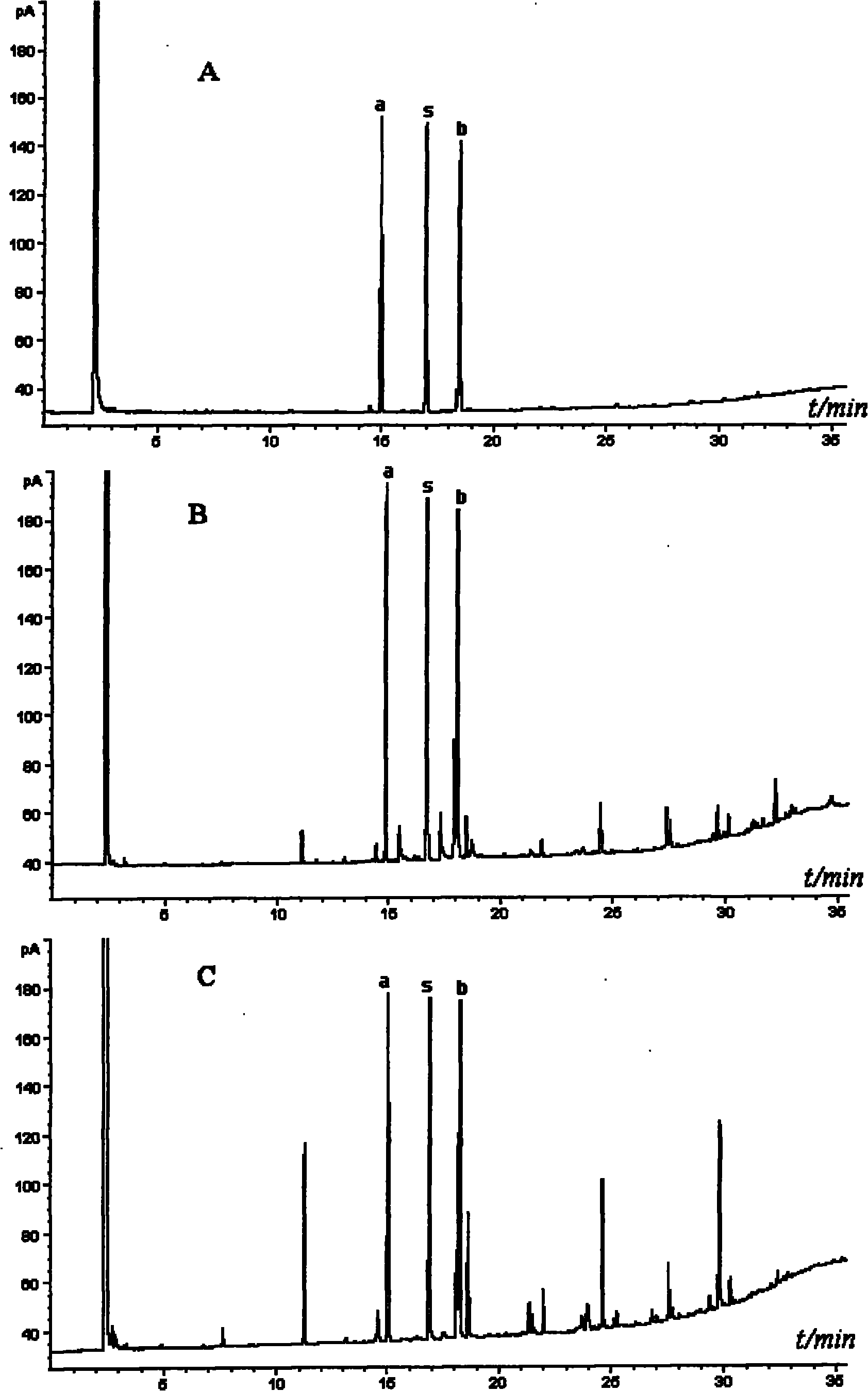

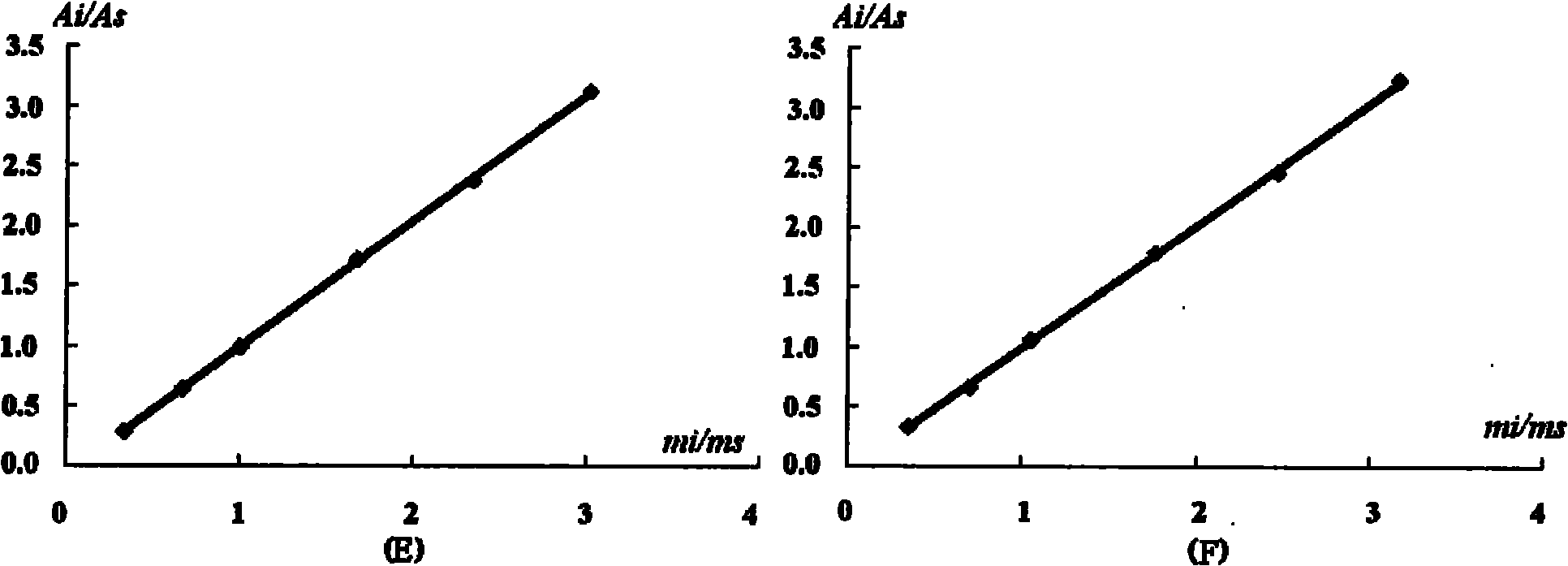

Image

Examples

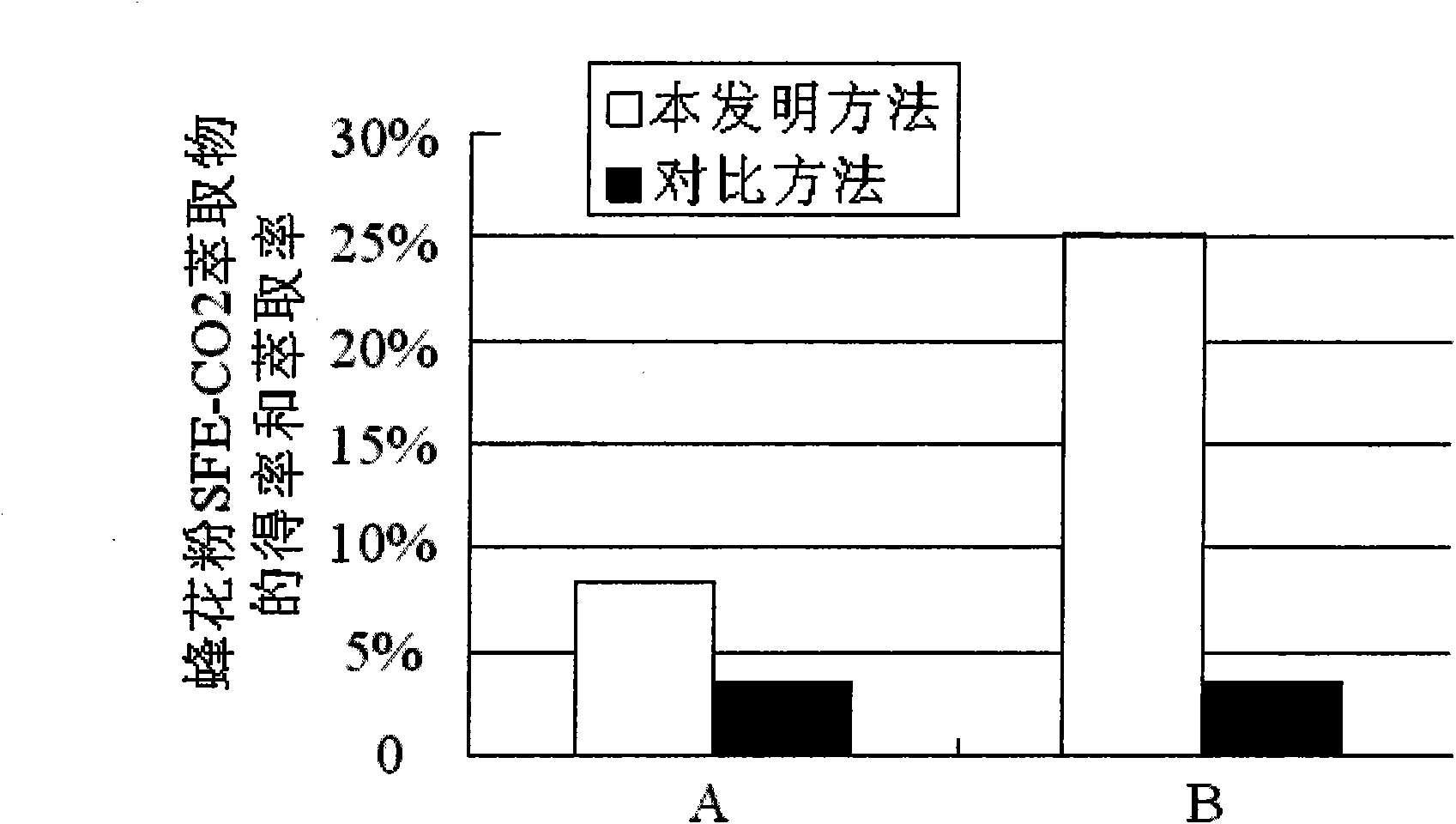

Embodiment 1

[0041] The method of the present invention: in the mixing tank of 600g of rapeseed bee pollen purchased in Baikang Bee Industry, Xuancheng City, Anhui Province, add 8L of distilled water, control the temperature in the mixing tank to be 37°C, stir for 30 hours, place in a centrifuge at 5000r / m Centrifuge for 30 minutes, pour off the supernatant, and then dry the centrifugal pellet at 60°C for 48 hours to obtain 200 g of washed dried rape bee pollen, with a water content of 6% by mass; then crush it and pass through 200 After the mesh sieve, put it into the extraction kettle of the supercritical carbon dioxide extraction device, control the temperature at 50°C, the pressure at 40MPa, the flow rate of carbon dioxide at 30L / h, and extract for 2 hours; the conditions for the primary separation are temperature at 45°C and pressure at 8Mpa; The conditions of secondary separation are temperature 35°C and pressure 4-6Mpa. Finally, 50 grams of rapeseed bee pollen supercritical carbon d...

Embodiment 2

[0049] The method of the present invention: put 500 g of corn bee pollen purchased from Baikang Bee Industry in Xuancheng City, Anhui into a mixing tank, add 6 L of distilled water, control the temperature in the mixing tank to be 37 ° C, and after stirring for 30 hours, filter, remove the filtrate, and filter the precipitate After spray drying, the conditions are: the air inlet temperature is 200°C; after the spray speed is 5000ml / h, 150g of dried corn bee pollen after washing with water is obtained, and the water content is 6% by mass; then it is pulverized and passed through 100 After the mesh sieve, put it into the extraction kettle of the supercritical carbon dioxide extraction device, control the temperature at 55°C, the pressure at 35MPa, the flow rate of carbon dioxide at 25L / h, and extract for 2 hours; the conditions for the primary separation are temperature at 35°C and pressure at 7Mpa; The conditions of secondary separation are temperature 30°C and pressure 4-6Mpa. ...

Embodiment 3

[0057] The method of the present invention: in the mixing tank of 800 g of green vegetable bee pollen purchased from Baikang Bee Industry in Xuancheng City, Anhui Province, add 15 L of distilled water, control the temperature in the mixing tank to be 37 ° C, and after stirring for 36 hours, filter, pour the filtrate, and then After the filtered precipitate was vacuum-dried at 60°C for 52 hours, 264g of water-washed dried cabbage bee pollen was obtained, with a water content of 8% by mass; then it was pulverized and passed through a 200-mesh sieve and then loaded into a supercritical carbon dioxide extraction device. In the extraction kettle, the temperature is controlled at 45°C, the pressure is 30MPa, the flow rate of carbon dioxide is 35L / h, and the extraction is performed for 2 hours; the conditions for primary separation are temperature 25°C, pressure 8Mpa; the conditions for secondary separation are temperature 30°C, pressure 4-6Mpa. Finally, 68.86 grams of rape bee polle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com