Preparation method and application of water-soluble carbon nano particles

A carbon nanoparticle, water-soluble technology, applied in the field of nanometers, can solve the problems of weakening the acidification function, unfavorable development and application of carbon nanoparticles, high temperature, etc., and achieve the effect of high quenching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

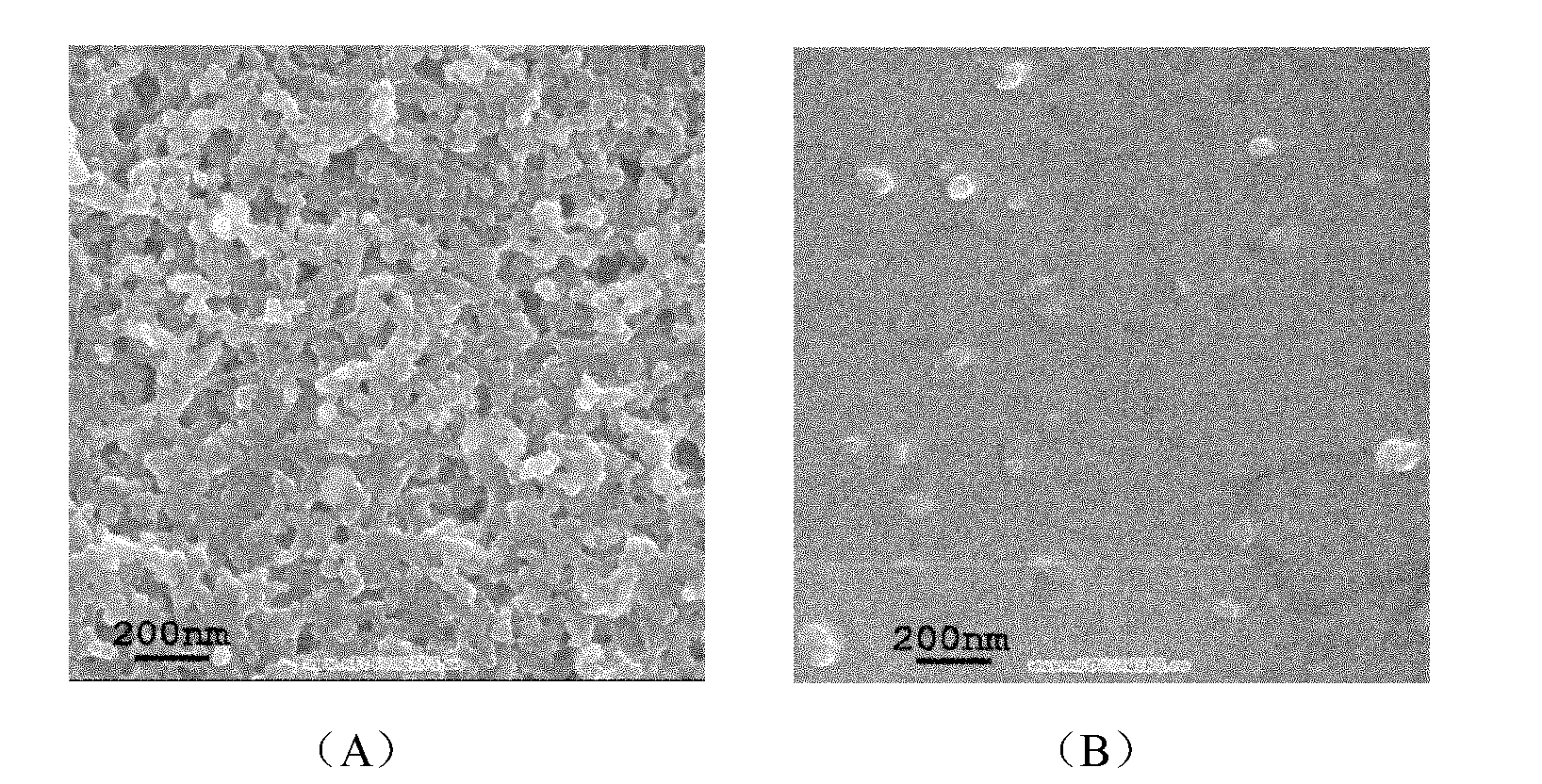

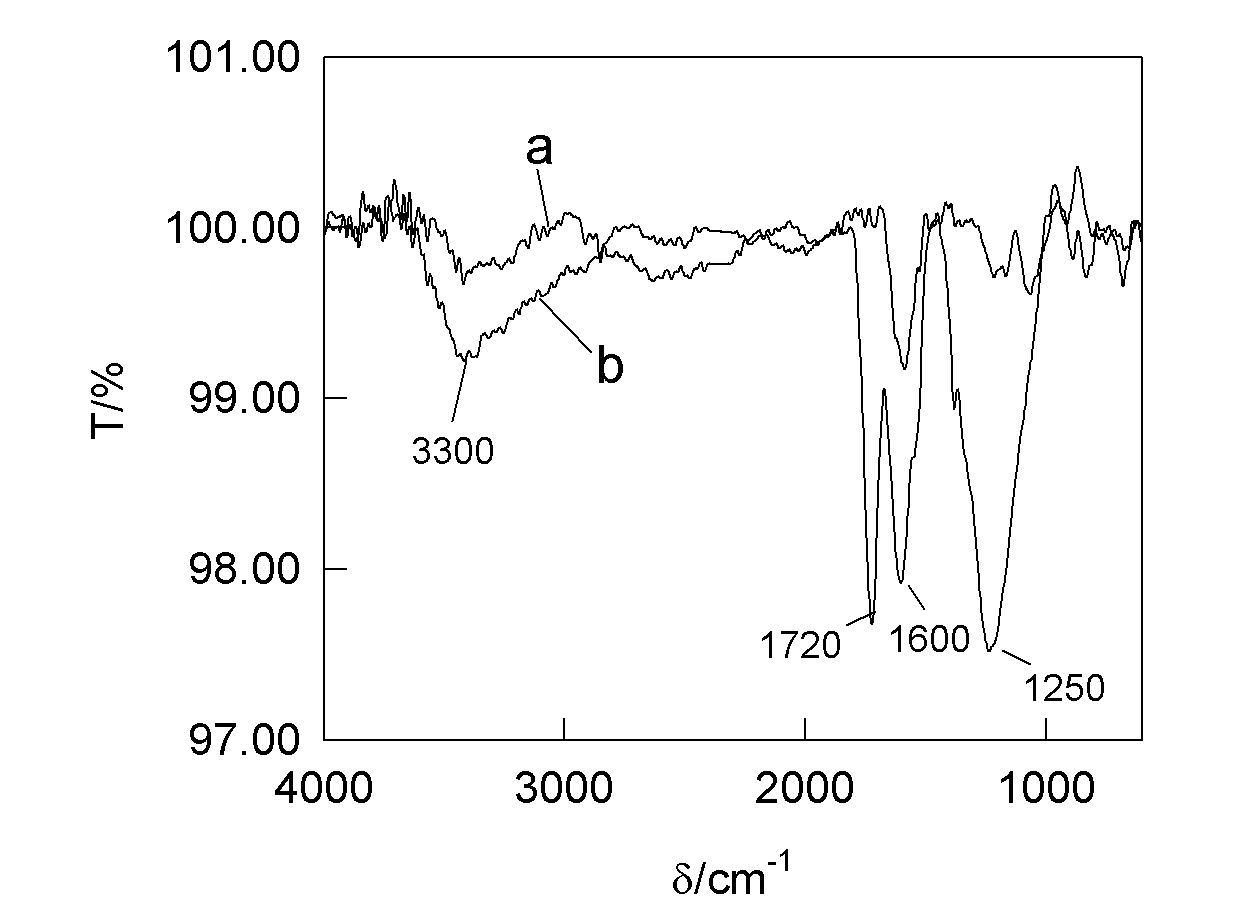

[0027] Embodiment 1: the beaker is placed on the burning candle to collect the black smoke, after a period of time the inside of the beaker deposits a layer of black solid, scrape off the black solid from the surface of the beaker; these black solids are placed in a vacuum oven to dry, Remove the moisture produced due to combustion to obtain dry carbon ash, store it in a dry environment for use; weigh 4mg of dry carbon ash in a 10mL round-bottomed flask, add 2mL of concentrated nitric acid and 2mL of DMF, at 60 Heat and reflux in an oil bath at ℃ for 12 hours; after the reflux, pour the reaction solution into a 5mL centrifuge tube and centrifuge. After centrifugation, it will be divided into two layers. Mix well and then centrifuge to remove the upper liquid, repeat this 5 times (the purpose is to remove the residual nitric acid in the reaction as much as possible, so as not to interfere with subsequent applications), add 2ml of secondary water to form an acidified carbon nanop...

Embodiment 2

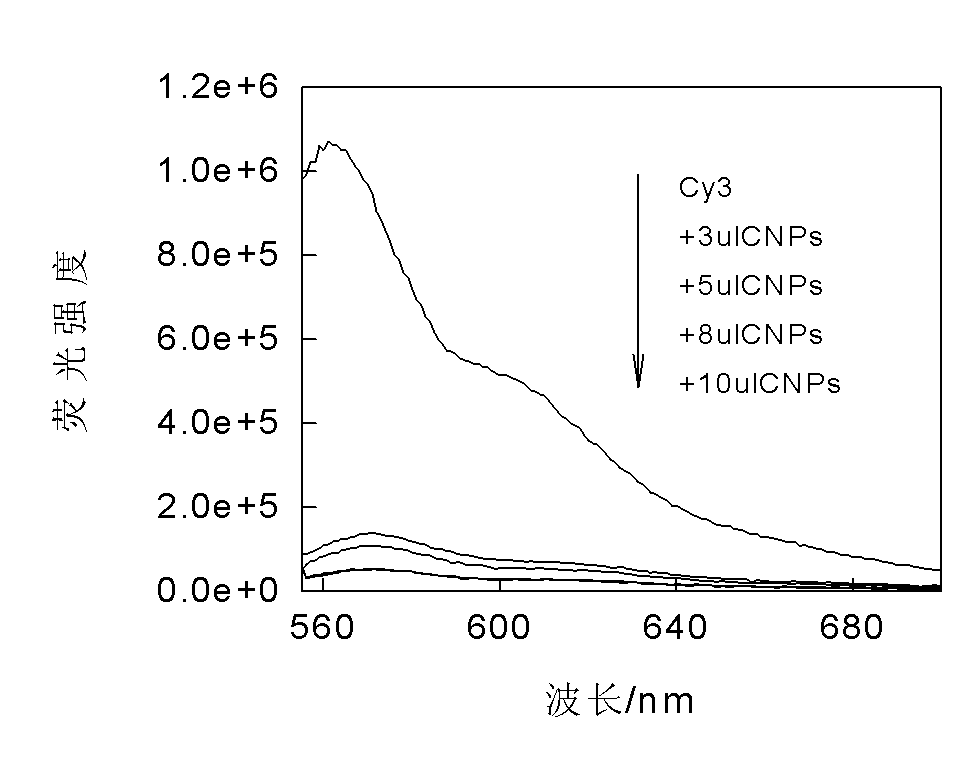

[0029] Embodiment 2: get Tris-HCl buffer solution (10mM Mg 2+ , 50mMK + , pH=7.4) 400 μL was added into the fluorescent cell with a volume of 800 μL, and dye Cy3 was added to the fluorescent cell so that the concentration of dye Cy3 was 60 nM; the fluorescence intensity was tested, and then 10 μL of acidified carbon nanoparticle solution (the acidified The concentrated reading of the carbon nanoparticle solution is 2 mg of acidified carbon nanoparticles per milliliter of the solution, that is, the concentration is 2 mg / ml, the same as the following), shake well, stand for 10 minutes, test and record the fluorescence intensity, and calculate the fluorescence intensity of the carbon nanoparticles. The quenching efficiency is 96.28%; if figure 2 .

Embodiment 3

[0030]Embodiment 3: get Tris-HCl buffer solution (10mM Mg2 + , 50mMK + , pH=7.4) 400 μL was added into the fluorescent cell with a volume of 800 μL, and the dye FAM was added in the fluorescent cell so that the concentration of the dye FAM was 60 nM, and the fluorescence intensity was tested; then 10 μL of acidified carbon nanoparticle solution (2 mg / ml ), shake well, place for 10min, then test and record its fluorescence intensity, calculate the quenching efficiency of carbon nanoparticles to fluorescence is 70.85%, as image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com