Method for modifying nano silicon dioxide for ink sucking coating

A nano-silica, ink-absorbing coating technology, applied in chemical instruments and methods, coatings, paper coatings, etc., can solve the problems of low ink-absorbing efficiency, poor hydrophilicity of nano-silica, and achieve ink-absorbing efficiency. The effect of improving, good physical tensile properties and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

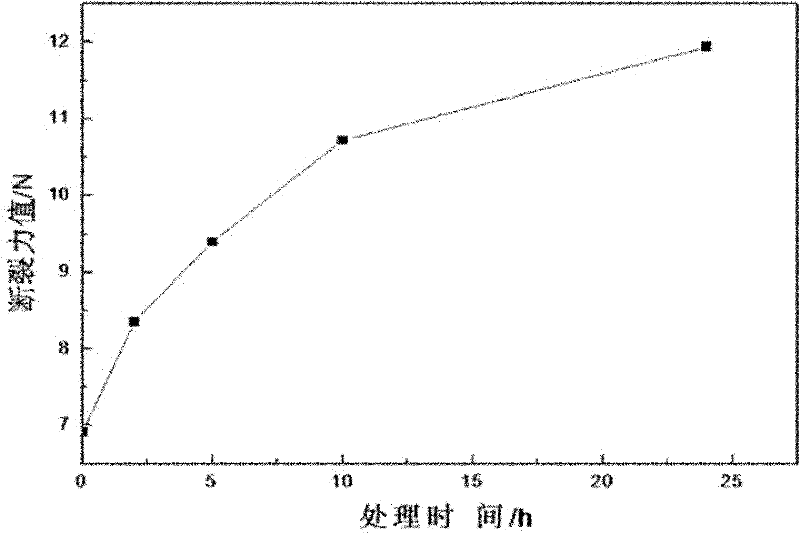

[0007] Specific embodiment one: In this embodiment, a method for modifying nano-silica for ink-absorbing coatings is carried out according to the following steps: 1. Take rare earth or rare earth mixture, make it fully dissolved in water, filter, constant volume, and prepare To obtain a rare earth solution with a mass concentration of 1% to 50%; 2. Mix the rare earth solution with nano-silicon dioxide, add 0.02g of nano-silicon dioxide to each milliliter of rare earth solution, and carry out the mixture under the condition of a constant temperature water bath at 25-120°C Modify, and keep stirring; 3. After the modification time is reached, stop the modification, centrifuge, pour out the supernatant, and the obtained precipitate is the modified nano-silica.

specific Embodiment approach 2

[0008] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, a rare earth solution with a mass concentration of 15% to 35% is prepared. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, a rare earth solution with a mass concentration of 25% is prepared. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com