Method for building optical proximity correction model, optical proximity correction method and mask

A technology for optical proximity correction and reticle, which is applied in the fields of optics, photo-engraving process of pattern surface, originals for opto-mechanical processing, etc. Improve chip performance and product yield, accurate optical proximity correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

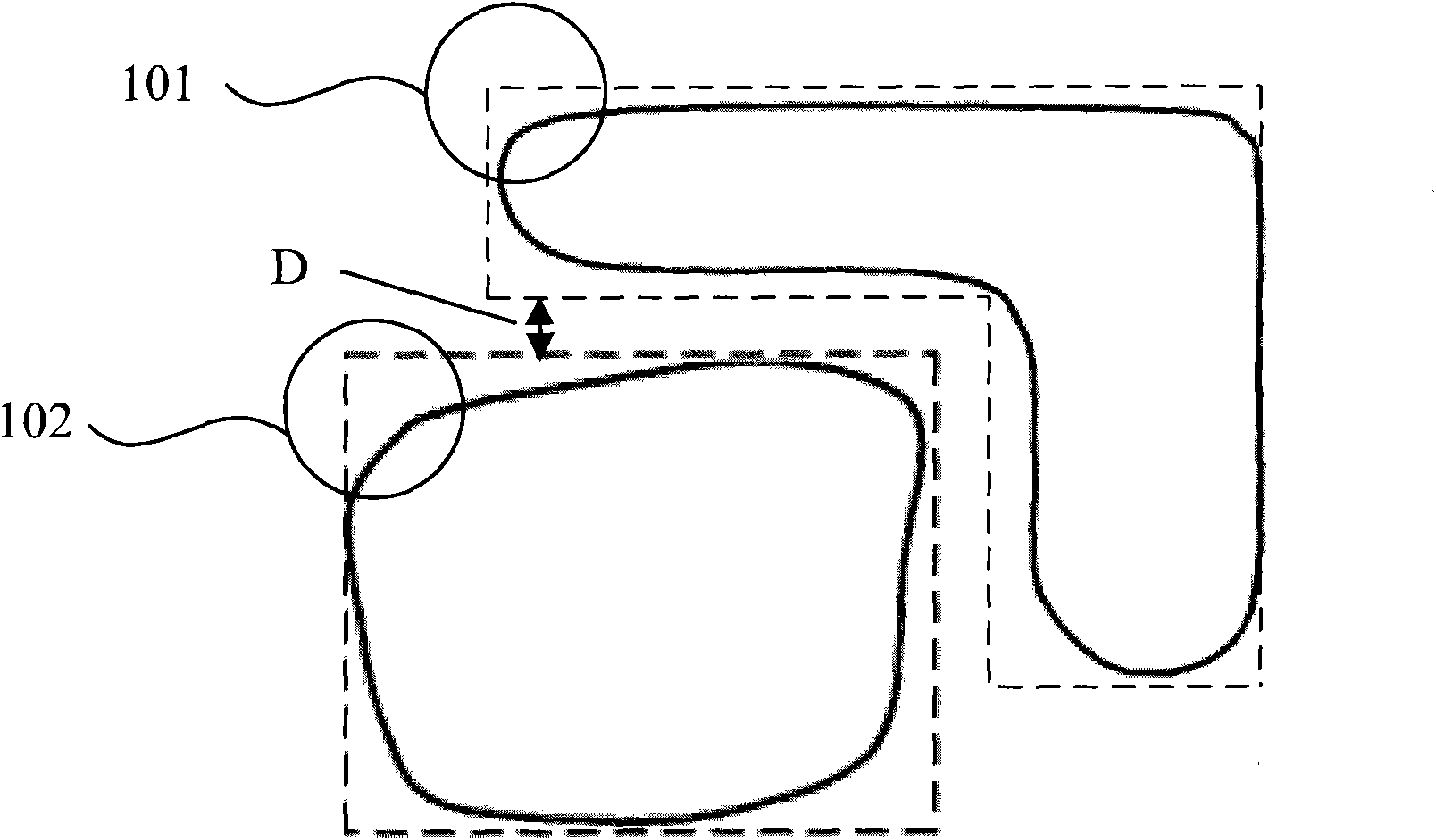

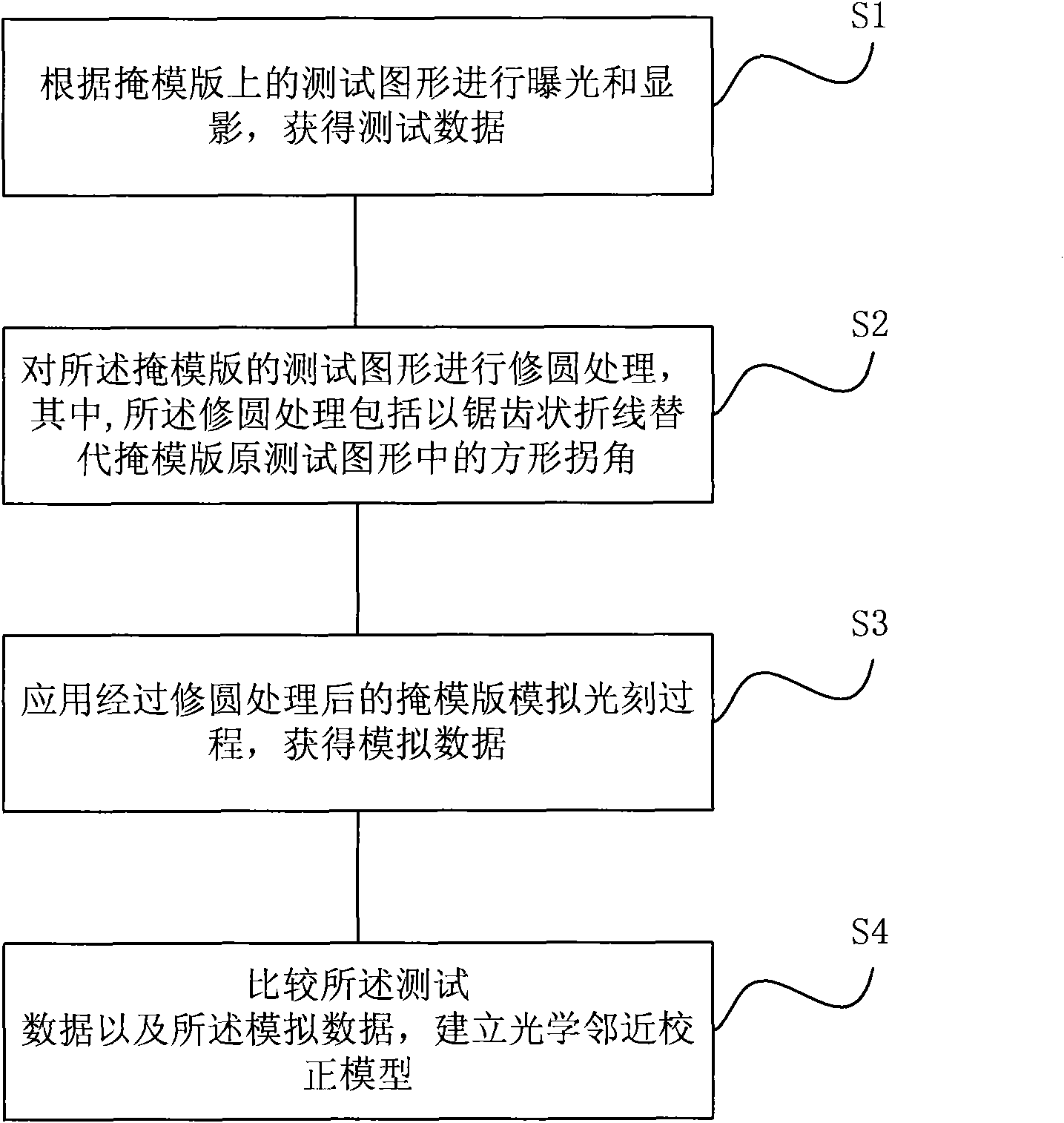

[0027] In model-based OPC, it is very important to accurately establish an optical proximity correction model that conforms to the actual exposure situation. Generally speaking, a test reticle can be used for exposure first, and the test data can be obtained by measuring the size of the exposure pattern obtained on the silicon wafer after the actual exposure; then the photolithography process can be simulated according to the test pattern on the test reticle used , obtain simulated data by measuring the size of the simulated result; then, compare the test data and simulated data to establish an optical proximity correction model, so that when the optical proximity correction model is applied to the simulated data, it is possible to obtain data same result.

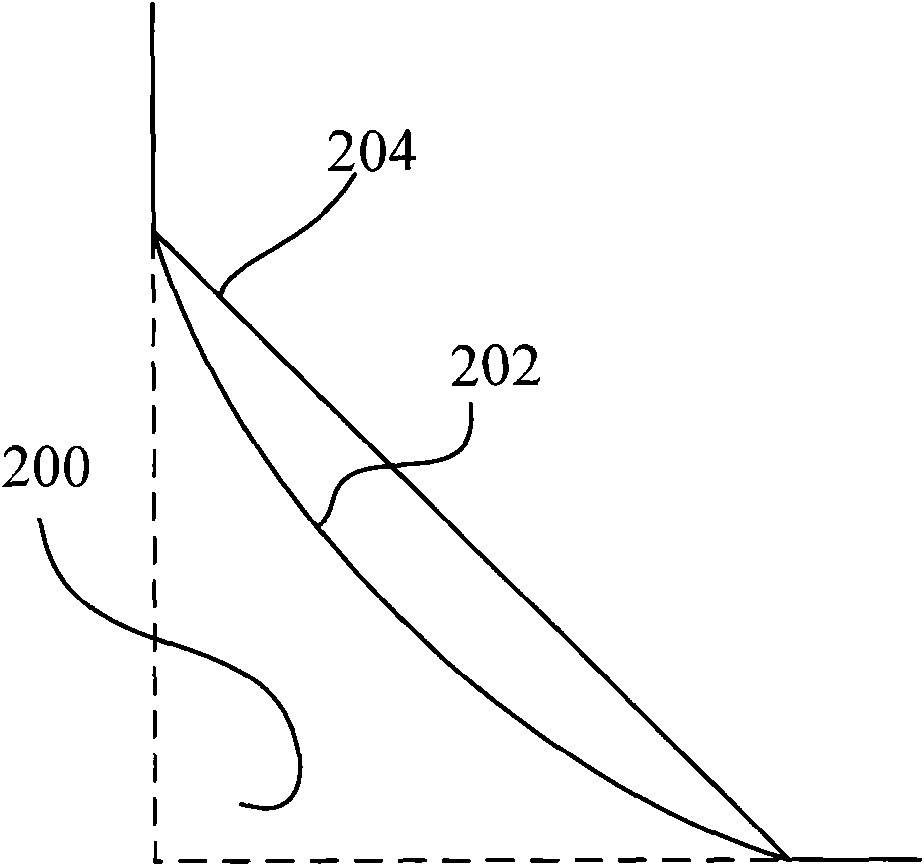

[0028] In actual lithography, when the test pattern on the mask plate is transferred to the photoresist layer through exposure and development steps, the pattern will appear square corners become rounded after development,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com