Electronic photographic photoreceptor and image forming device

An electrophotographic and photoreceptor technology, applied in the field of electrophotographic photoreceptors, image forming devices, and single-layer electrophotographic photoreceptors, can solve the problem that the generation of fog cannot be suppressed, the application of positively charged organic photoreceptors has not carried out any research, Problems such as fog generation, to achieve the effect of suppressing the generation of fog, suppressing fog, and increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

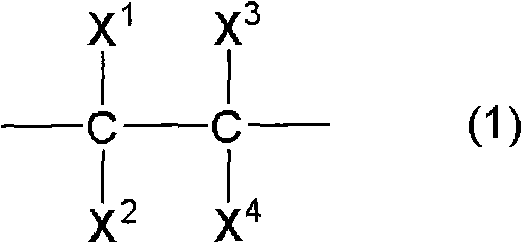

[0111] The X-type metal-free phthalocyanine crystal shown in the chemical formula (6) that accommodates 3 parts by mass as a charge generating agent in the container, the stilbene amine compound shown in the chemical formula (4) as the hole transport agent in 50 parts by mass, 30 The naphthoquinone compound shown in the chemical formula (5) as the electron transport agent of mass parts, the bisphenol Z type polycarbonate resin (number average) shown in the chemical formula (2-1) of 95 mass parts as binder resin Molecular weight: 30000), 5 parts by mass of polyvinyl chloride (manufactured by NACALAI TESQUE Co., Ltd., product number 36305-65, hereinafter sometimes abbreviated as olefin polymer 1), and 700 parts by mass of tetrahydrofuran as a solvent.

[0112] Next, these materials accommodated in the container were mixed and dispersed for 50 hours using a ball mill, thereby preparing a coating liquid for a photosensitive layer.

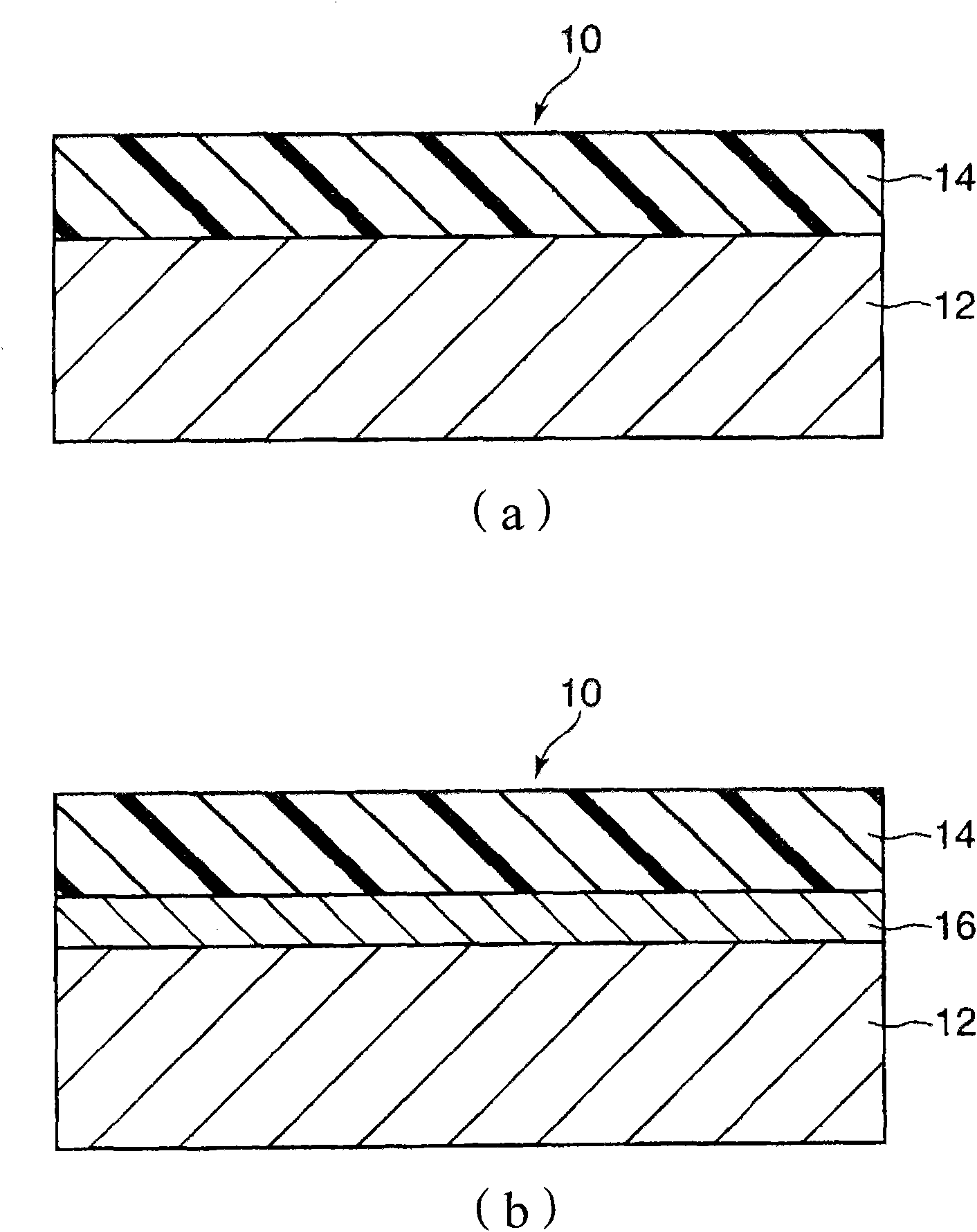

[0113] Next, the prepared photosensitive layer c...

Embodiment 2

[0116] As the binder resin, use 90 parts by mass of bisphenol Z-type polycarbonate and 10 parts by mass of polyvinyl chloride instead of 95 parts by mass of bisphenol Z-type polycarbonate resin and 5 parts by mass of polyvinyl chloride, in addition Other than that, a single-layer electrophotographic photoreceptor was produced in the same manner as in Example 1.

Embodiment 3

[0118] As the binder resin, use 80 parts by mass of bisphenol Z-type polycarbonate and 20 parts by mass of polyvinyl chloride instead of 95 parts by mass of bisphenol Z-type polycarbonate resin and 5 parts by mass of polyvinyl chloride, in addition Other than that, a single-layer electrophotographic photoreceptor was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Line speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com