Flexible transparent conductive film, flexible functional device, and methods for producing these

A technology of transparent conductive film and manufacturing method, applied in electrical components, cable/conductor manufacturing, chemical instruments and methods, etc., can solve the problems of no recorded value and no record, and achieve the effect of excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

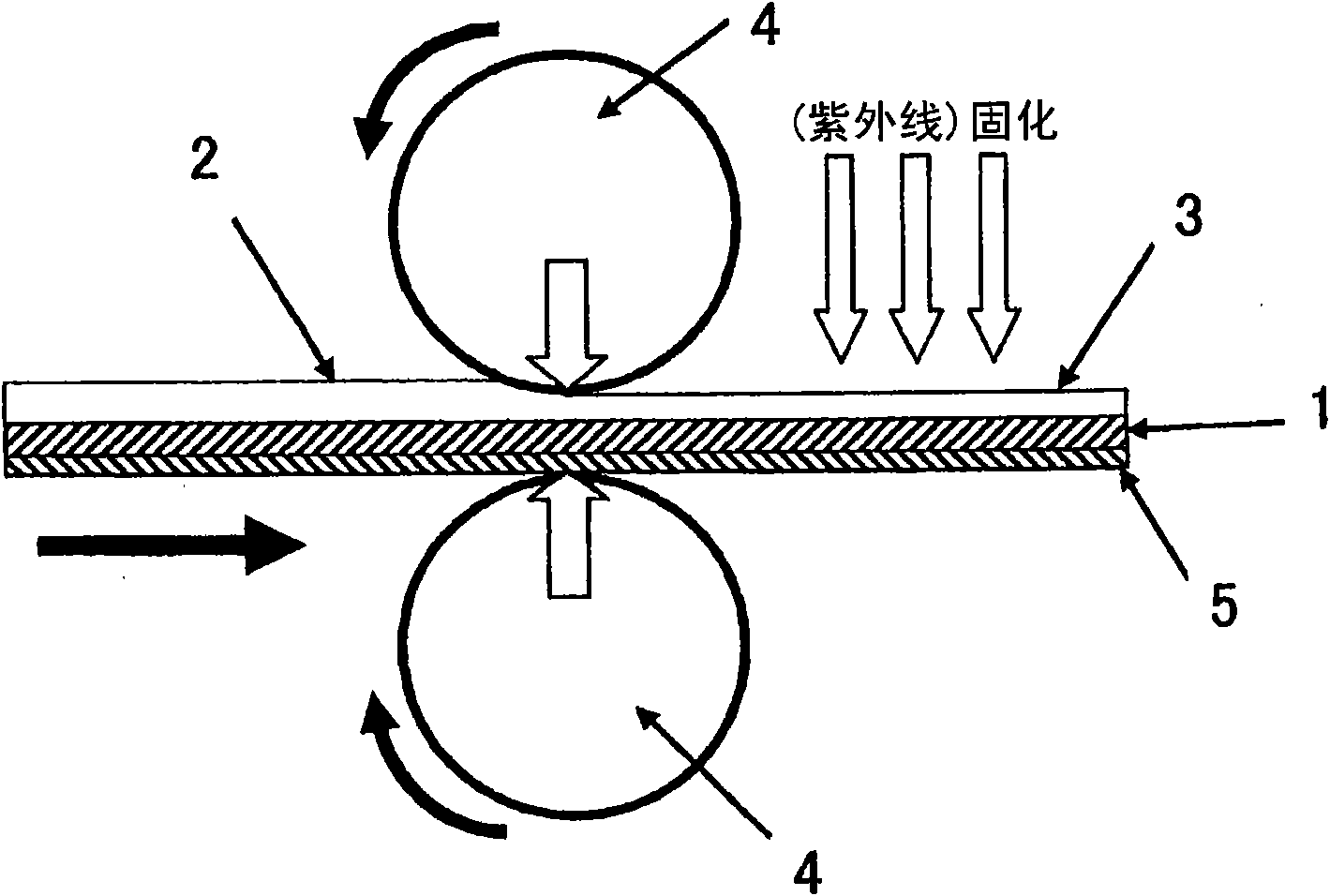

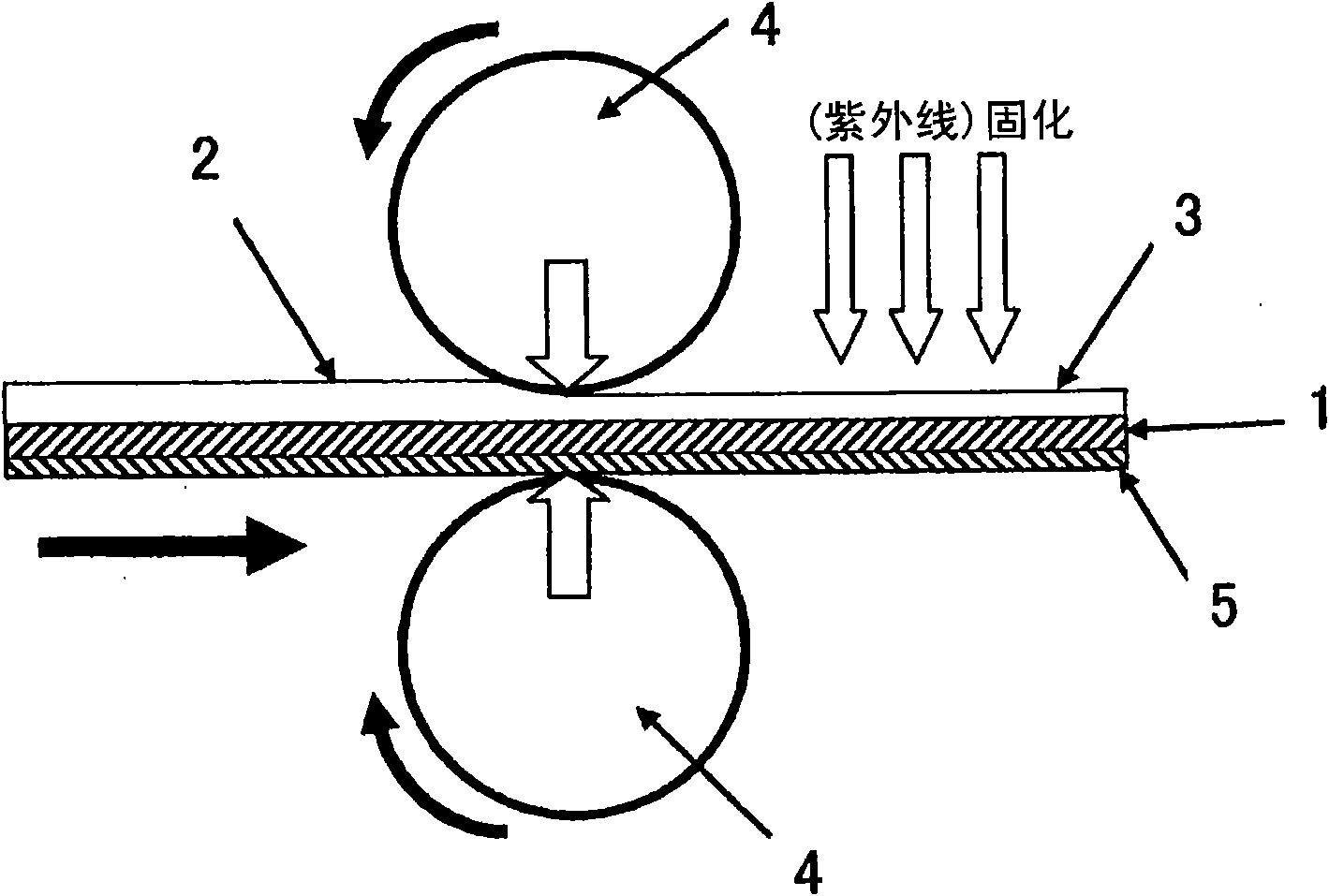

[0072] In 24 g of methyl isobutyl ketone (MIBK) and 36 g of cyclohexanone as a solvent, mixing 36 g of granular ITO microparticles [trade name: SUFP-HX, manufactured by Sumitomo Metal Mining Co., Ltd.] with an average particle diameter of 0.03 μm, After carrying out the dispersion treatment, add 3.8g urethane acrylate UV-curable resin binder and 0.2g photoinitiator [trade name: ダロキユア-1173, manufactured by Ciba Japan Ltd.], and stir well, thus prepare a uniform dispersion. A coating liquid (liquid A) for forming a transparent conductive layer of ITO microparticles having a particle diameter of 125 nm.

[0073] Next, before producing a flexible transparent conductive film, a plastic film with a thickness of about 13 μm [Toppan Printing Co., Ltd., trade name: GX-P-F film (hereinafter referred to as "GX film"), GX Film composition: PET film (thickness: 12μm) / vapor-deposited aluminum oxide gas barrier layer (thickness: 10-tens of nm) / silicate-polyvinyl alcohol mixed coating (co...

Embodiment 2

[0093]Before producing the flexible transparent conductive film, the gas barrier layers (made of aluminum oxide) of two plastic films [trade name: GX film, manufactured by Toppan Printing Co., Ltd.] with a thickness of about 13 μm used in Example 1 were bonded together with an adhesive Between the gas barrier layer and the silicate-polyvinyl alcohol mixed coating), the gas barrier performance enhancement film is produced [film composition: PET film (thickness: 12 μm) / vapor-deposited aluminum oxide gas barrier layer (thickness: 10 ~ tens of nm) / silicate-polyvinyl alcohol mixed coating (coating film, thickness: 0.2-0.6μm) / adhesive layer (about 8μm) / silicate-polyvinyl alcohol mixed coating (coating Film, thickness: 0.2~0.6μm) / evaporated aluminum oxide gas barrier layer (thickness: 10~tens of nm) / PET film (thickness: 12μm), the water vapor transmission rate of the film is lower than 0.01g / m 2 / day (that is, the water vapor transmission rate of the film 2 / day), visible light tra...

Embodiment 3

[0104] In 24 g of methyl isobutyl ketone (MIBK) and 36 g of cyclohexanone as a solvent, mixing 36 g of granular ITO microparticles [trade name: SUFP-HX, manufactured by Sumitomo Metal Mining Co., Ltd.] with an average particle diameter of 0.03 μm, After the dispersion treatment, 4.0 g of a liquid thermosetting epoxy resin binder was added and stirred to prepare a coating solution (B solution) for forming a transparent conductive layer in which ITO fine particles having an average particle diameter of 130 nm were dispersed.

[0105] Next, before manufacturing the flexible transparent conductive film, a plastic film with a thickness of about 13 μm [manufactured by Dainippon Printing Co., Ltd., trade name: IB-PET-PXB film (hereinafter referred to as "IB film" ), composition of IB film: PET film (thickness: 12 μm) / evaporated alumina gas barrier layer (thickness: 10 to tens of nm) / silicate-polyvinyl alcohol mixed coating (coating film, thickness: 0.2 ~0.6μm), the water vapor transm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com