A kind of intelligent moisture control film and preparation method and application

A thin film and intelligent technology, applied in the field of intelligent moisture control film and preparation, can solve the problems of high cost, complex process, lack of intelligent moisture control, etc., and achieve the effect of low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A second aspect of the present invention provides a preparation method of an intelligent moisture control film, the preparation method comprising the following steps:

[0028] (1) fully dissolving or dispersing each component of the functional layer of the above-mentioned intelligent moisture control film in water to prepare a solution or dispersion;

[0029] (2) attaching the solution or dispersion obtained in the step (1) to one side or both sides of the support layer of the above-mentioned intelligent moisture control film, and forming a functional layer on the support layer;

[0030] (3) After drying the support layer with the functional layer attached in step (2), contact with the tannic acid aqueous solution to form a cross-linked modified layer on the functional layer, and dry to obtain the intelligent moisture control film.

[0031] According to the present invention, the mass concentration of the solution or dispersion in step (1) is preferably 0.5%-30%, more p...

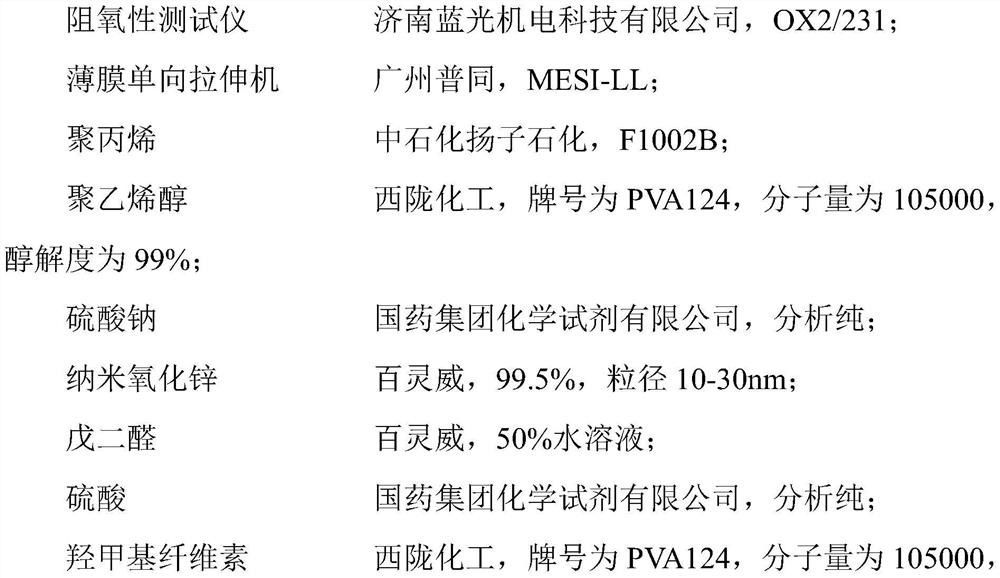

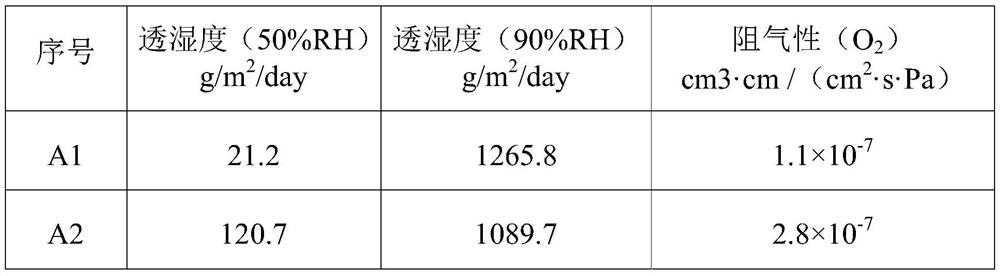

Embodiment 1

[0043] Take 2kg of polypropylene and stretch it into a porous film on a film uniaxial stretching machine. Then add 4g of polyvinyl alcohol into 100mL of distilled water to fully dissolve, and then add 2.1g of sodium sulfate, 0.2g of nano-zinc oxide, 0.35g of glutaraldehyde and 0.1g of sulfuric acid to the above mixed solution, and fully stir until the mixture is uniform. The uniformly mixed solution was evenly brushed on the polypropylene porous film, then placed in an oven, dried at 70 ° C for 10 min, and then the obtained dried film was immersed in a 5% mass concentration of tannic acid aqueous solution , take it out after 3 min, put it in an oven, and dry it at 70°C for 10 min to obtain the intelligent moisture-controlling film A1.

Embodiment 2

[0045] Take 2kg of polypropylene and stretch it into a porous film on a film uniaxial stretching machine. Take 7g of hydroxymethyl cellulose and add it to 100mL of distilled water to fully dissolve it, then add 1.4g of lithium fluoride, 0.2g of nano-zinc oxide, 4g of formaldehyde and 0.1g of sulfuric acid to the above mixed solution, and fully stir until the mixture is uniform. The uniformly mixed solution was evenly brushed on the polypropylene porous film, then placed in an oven, dried at 70 °C for 10 min, and then the obtained dried film was immersed in a 7.5% mass concentration of tannic acid aqueous solution , taken out after 3 min, put into an oven, and dried at 70° C. for 10 min to obtain the intelligent moisture control film A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com