Method for decomposing high-concentration methane mixed gas by fast photocatalysis by using low pressure mercury lamp

A low-pressure mercury lamp, photocatalytic technology, applied in separation methods, chemical instruments and methods, chemical/physical/physicochemical processes using energy, etc., to achieve the effect of low conversion cost, fast conversion rate and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

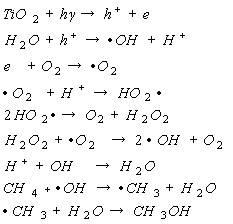

Problems solved by technology

Method used

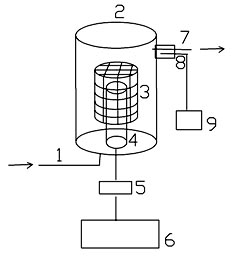

Image

Examples

Embodiment 1

[0027] The mixed gas uses the mixed gas of the high-pressure steel cylinder, and the CH in the gas 4 The content accounts for about 90%, CO 2 About 10%;

[0028] A glass reaction device is adopted, and the effective volume of the device is 2.2L; the main wavelength of the low-pressure mercury lamp used is 253.4nm, and the power is 20W; a cylindrical titanium mesh plate with a radius of 5cm and a height of 12.5cm is used to cover the light-emitting part of the low-pressure mercury lamp ; In addition, the temperature and humidity recorder of Hangzhou Zeda Instrument Factory was used to record the temperature and humidity changes during the entire reaction process.

[0029] Step 1: Connect the experimental device and install the catalyst to coat TiO 2 After the titanium screen, pass the mixed gas into the reaction container, adjust the content and humidity of the gas, measure the gas at the gas outlet, wait until the methane content in the container reaches 0.6542g / L, and the r...

Embodiment 2

[0036] The mixed gas uses the mixed gas of the high-pressure steel cylinder, and the CH in the gas 4 The content accounts for about 50%, CO 2 About 50%;

[0037]A glass reaction device is adopted, and the effective volume of the device is 2.2L; the main wavelength of the low-pressure mercury lamp used is 253.4nm, and the power is 20W; a cylindrical titanium mesh plate with a radius of 5cm and a height of 12.5cm is used to cover the light-emitting part of the low-pressure mercury lamp ; In addition, the temperature and humidity recorder of Hangzhou Zeda Instrument Factory was used to record the temperature and humidity changes during the entire reaction process.

[0038] Step 1: Connect the experimental device and install the catalyst to coat TiO 2 After the titanium screen, pass the mixed gas into the reaction container, adjust the content and humidity of the gas, measure the gas at the gas outlet, wait until the methane content in the container reaches 0.3820g / L, and the re...

Embodiment 3

[0045] The mixed gas uses the mixed gas of the high-pressure steel cylinder, and the CH in the gas 4 The content accounts for about 10%, CO 2 About 90%;

[0046] A glass reaction device is adopted, and the effective volume of the device is 2.2L; the main wavelength of the low-pressure mercury lamp used is 253.4nm, and the power is 20W; a cylindrical titanium mesh plate with a radius of 5cm and a height of 12.5cm is used to cover the light-emitting part of the low-pressure mercury lamp ; In addition, the temperature and humidity recorder of Hangzhou Zeda Instrument Factory was used to record the temperature and humidity changes during the entire reaction process.

[0047] Step 1: Connect the experimental device and install the catalyst to coat TiO 2 After the titanium screen, pass the mixed gas into the reaction container, adjust the content and humidity of the gas, measure the gas at the gas outlet, wait until the methane content in the container reaches 0.0073g / L, and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Dominant wavelength | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com