Ceramic casting mold applied to metal casting under electric field treatment and method for casting titanium aluminum-based alloy by using same

A ceramic casting mold and base alloy technology, which is applied in the field of casting titanium-aluminum base alloys, can solve the problems of difficulty in controlling the orientation of solid-phase precipitation sheets, uneven current density distribution, and small effective area of electric field, etc., to achieve crystal grain The effect of tissue refinement, uniform current density distribution, and enlarged effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

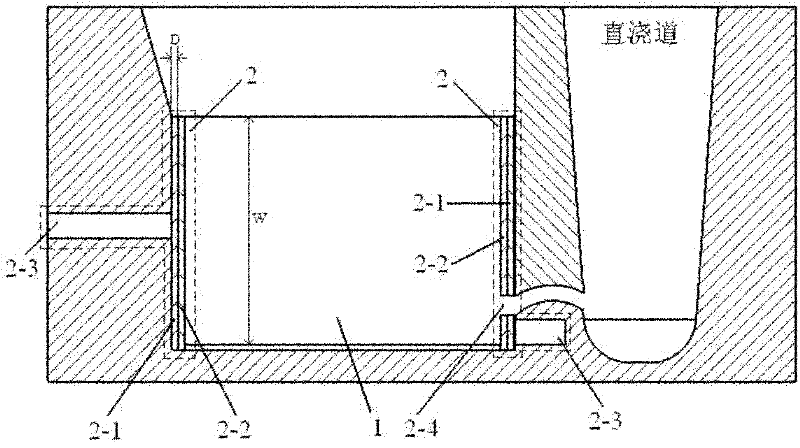

[0021] Specific implementation mode 1: This implementation mode is combined with the description attached figure 1 The ceramic casting mold for casting metal under electric field treatment is described, and the ceramic casting mold for casting metal under electric field treatment is respectively provided with the side shape of the cavity 1 on the two opposite sides of the ceramic casting mold cavity 1. Homogeneous composite electrode 2, the two homogeneous composite electrodes 2 set are composed of copper plate 2-1, alloy plate 2-2 and copper terminal 2-3, wherein the copper terminal 2-3 is set on the copper plate 2- 1, the other side of the red copper plate 2-1 is welded with the alloy plate 2-2, and one of the homogeneous composite electrodes 2 is provided with a sprue 2-4, and the sprue 2-4 is connected to the sprue Communication; one side of the copper plate 2-1 where the copper terminal 2-3 is set is connected to the side of the mold cavity 1, and the copper terminal 2-3 ...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that the alloy plate 2-2 is a metal material plate such as a titanium alloy plate, a titanium-aluminum alloy plate, an aluminum alloy, or a cast iron plate. Other parameters are the same as in the first embodiment.

[0024] In this embodiment, the specific type of the alloy plate 2-2 depends on the type of metal cast in the ceramic mold, that is, the specific type of the alloy plate 2-2 is the same as the metal type cast in the ceramic mold.

specific Embodiment approach 3

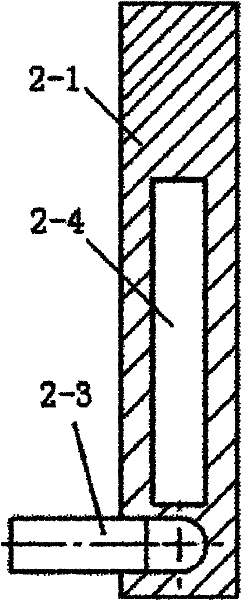

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the red copper terminal 2-3 is arranged on one side of the red copper plate 2-1, and the homogeneous composite electrode 2 with the gate 2-4 is arranged therein. The red copper terminal 2-3 is arranged below the pouring port 2-4 on the red copper plate 2-1. Other parameters are the same as those in Embodiment 1 or Embodiment 2.

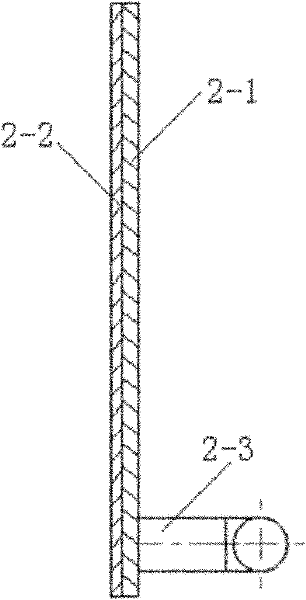

[0026] The front view of the homogeneous composite electrode 2 provided with the sprue 2-4 in this embodiment is as follows figure 2 As shown, the right view is as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com