Silica micropowder loaded type nano zerovalent iron particle and preparation method thereof

A technology of nano-zero-valent iron and silicon micropowder, which is applied in the field of nano-material preparation to achieve the effect of simple process, simple equipment and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

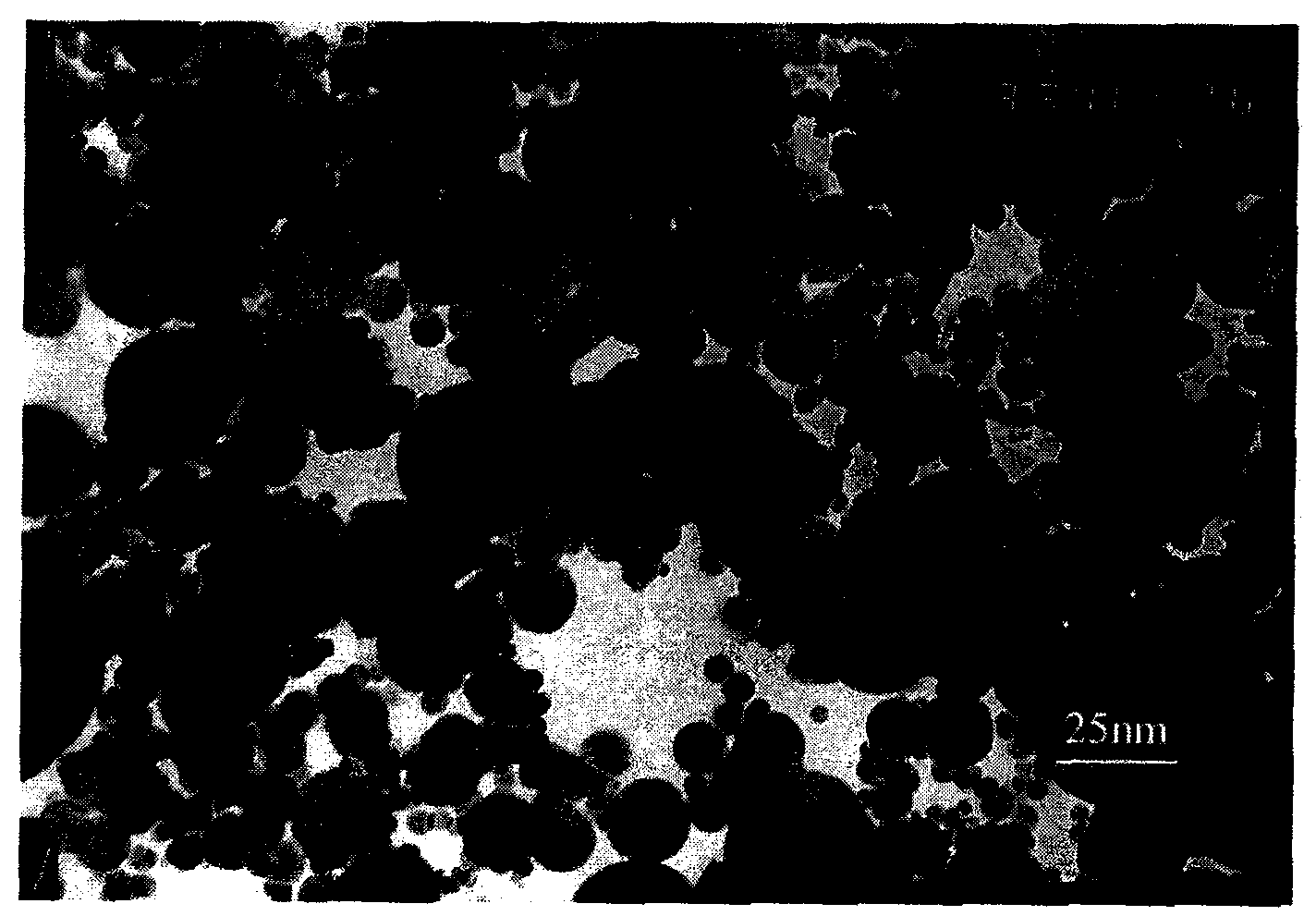

Image

Examples

Embodiment 1

[0033] A preparation method of silicon micropowder-loaded nanometer zero-valent iron particles, comprising the following steps:

[0034] (1) Preparation of modified silica powder:

[0035] Prepare 13g / L silicon micropowder slurry, then add 1.7mol / L hydrochloric acid solution, stir evenly, settle naturally for 3 hours, and take the upper layer slurry and centrifuge it.

[0036] (2) Deoxygenation:

[0037] Dissolve the above-mentioned centrifuged silicon micropowder in anhydrous FeCl 3 In the mixed solution (volume ratio of alcohol and water is 3:7), the molar concentration of iron ions is 0.011mol / L, nitrogen gas is introduced to remove oxygen for 20 minutes, and mechanically stirred for 10 minutes to make the mixing uniform and sufficient to obtain a mixed solution.

[0038] (3) Preparation of nano-iron solution:

[0039] Add 10ml of 0.268mol / L freshly prepared KBH dropwise to the mixed solution under mechanical stirring 4 solution, and reacted for 30 minutes to obtain a b...

Embodiment 2

[0043] When preparing the black nano-iron solution, the reactant uses NaBH 4 Solution Replacement KBH 4 solution, and others are the same as in Example 1.

Embodiment 3

[0045] A preparation method of silicon micropowder-loaded nanometer zero-valent iron particles, comprising the following steps:

[0046] (1) Preparation of modified silica powder:

[0047] Prepare 13g / L silicon micropowder slurry, then add 1.3mol / L hydrochloric acid solution, stir evenly, settle naturally for 2.5h, take the upper layer slurry and centrifuge.

[0048] (2) Deoxygenation:

[0049] Dissolve the above-mentioned centrifuged silicon micropowder in anhydrous FeCl 3 In the mixed solution (alcohol-water volume ratio is 3:7), the molar concentration of iron ions is 0.014mol / L, nitrogen deoxygenation is introduced for 30min, mechanically stirred for 10min to make the mixing uniform and sufficient, and a mixed solution is obtained.

[0050] (3) Preparation of nano-iron solution:

[0051] Add 10ml of 0.358mol / L freshly prepared KBH dropwise to the mixed solution under mechanical stirring 4 solution, and reacted for 35 minutes to obtain a black nano-iron solution.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com