Method for treating wastewater by utilizing composite microbial preparation

A technology for composite microorganisms and wastewater treatment, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as increasing the operating cost of sewage treatment projects, and achieve the promotion of utilization and metabolic decomposition , Efficient reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

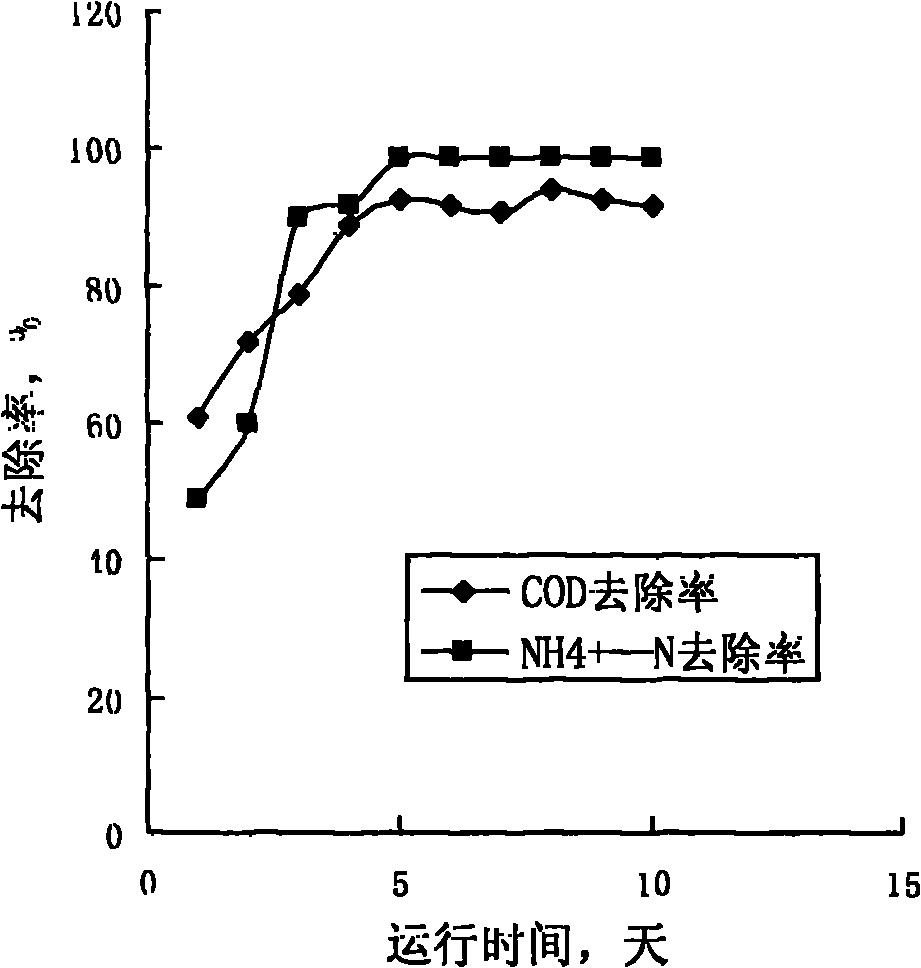

Embodiment 1

[0020] This embodiment is carried out as follows:

[0021] The wastewater is a certain leather wastewater in Fujian. After physical and chemical treatment, the wastewater directly enters the biological treatment system. The water quality indicators of the biological treatment system are as follows:

[0022] COD: 2000--2500mg / l

[0023] NH 4 + -N: 190mg / l

[0024] PH value: 8.0-9.5

[0025] The project water volume is 4000m 3 / d, A (contemporaneous oxygen) / O (aerobic) process, the operating process conditions are as follows:

[0026] Residence time: 48h, facultative aerobic 12h, aerobic 48h

[0027] Temperature: 25-35℃

[0028] Aerobic DO: 2~5mg / l

[0029] The dosage of the carrier: 1.5% of the pool volume

[0030] Put a compound microbial agent with an initial concentration of 1.5‰ of the biological tank processing volume into the biochemical tank, and put 1% of the tank volume in powdered diatomaceous earth or powdered activated carbon. The particle size of powdered diatomaceous earth or p...

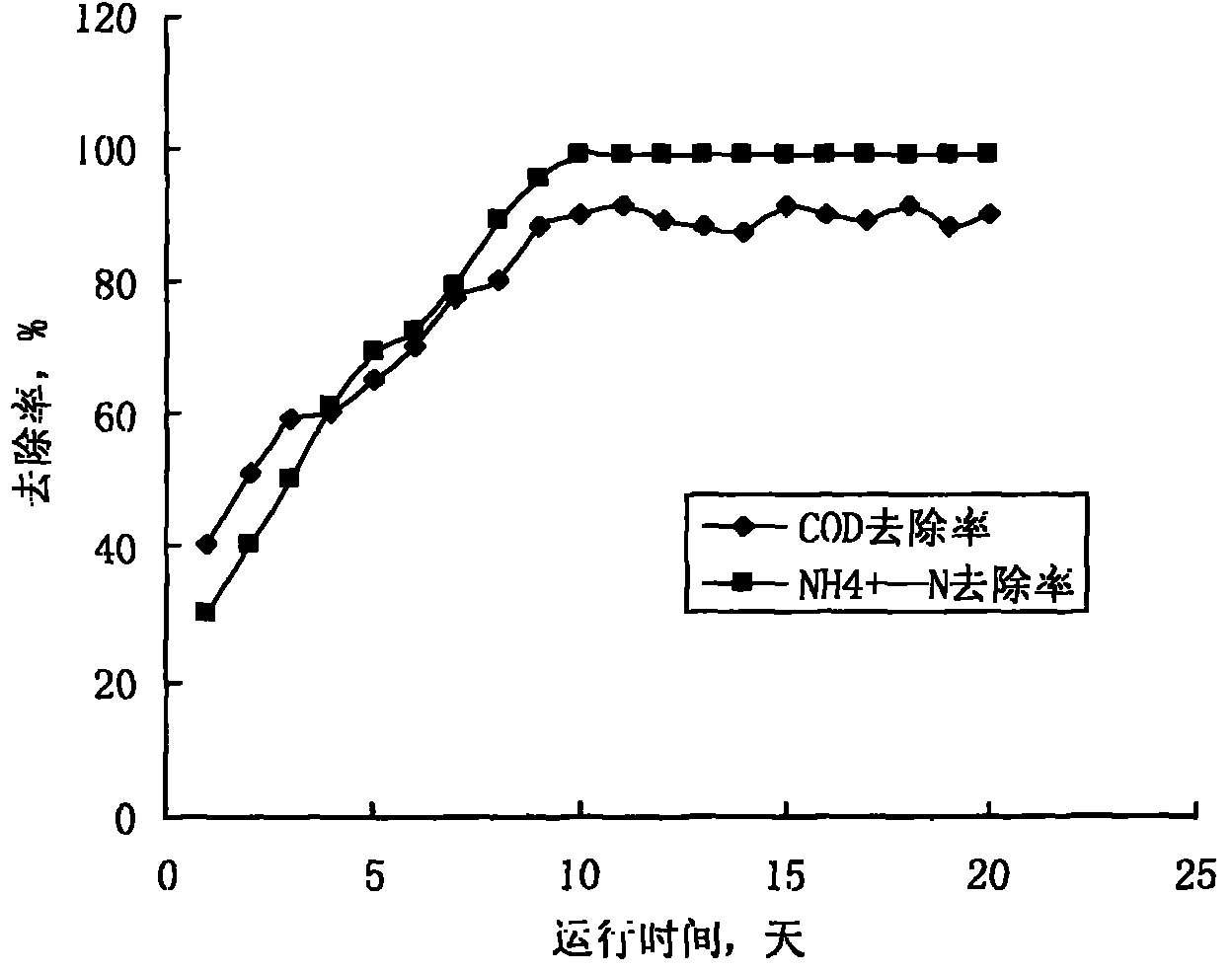

Embodiment 2

[0034] This embodiment is carried out as follows:

[0035] The wastewater is ammonia-containing wastewater from a synthetic ammonia company in Hefei. After being treated by air flotation and degreasing, the wastewater directly enters the biological treatment system. The water quality indicators entering the biological treatment system are as follows:

[0036] COD: 400--600mg / l

[0037] NH 4 + -N: 300--400mg / l

[0038] PH value: 8.5-9.0

[0039] The project water volume is 2000m 3 / d, A (contemporaneous oxygen) / O (aerobic) process, the operating process conditions are as follows:

[0040] Residence time: 36h, facultative aerobic 12h, aerobic 24h

[0041] Temperature: 25-35℃

[0042] Aerobic and aerobic DO: 2~5mg / l

[0043] Dosing amount of carrier: 1.0% of pool volume

[0044] Put the compound microbial agent with an initial concentration of 2.0‰ of the biological tank processing volume into the biochemical tank, and put in powder diatomaceous earth or powdered activated carbon of 2% of the t...

Embodiment 3

[0048] This embodiment is carried out as follows:

[0049] The wastewater is coking wastewater from a coking plant in Shijiazhuang. After being treated by air flotation and degreasing, the wastewater directly enters the biological treatment system. The water quality indicators of the biological treatment system are as follows:

[0050] COD: 5000--6000mg / l

[0051] NH 4 + -N: 200--400mg / l

[0052] PH value: 7.5---9.0

[0053] The project water volume is 1500m 3 / d, A (anaerobic) / A (facultative oxygen) / O (aerobic) process, the operating process conditions are as follows:

[0054] Residence time: 76h, anaerobic 8h, facultative aerobic 20h, aerobic 48h

[0055] Temperature: 25-35℃

[0056] DO: 2~5mg / l

[0057] Carrier dosage: 2% of the pool volume

[0058] Put the compound microbial preparation with the initial concentration of 3.0‰ of the biological tank processing volume into the biochemical tank, and put 1.5% of the tank volume into powdered diatomaceous earth or powdered activated carbon. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com