FRP-bamboo-concrete combination beam

A technology of concrete and composite beams, applied to bridges, joists, girders, etc., can solve the problems of inconsistent ductility requirements of structural members, unimproved elastic modulus, discrete actual mechanical properties, etc., to achieve large bearing capacity and improved Good effect on section moment of inertia, ductility and self-recovery ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

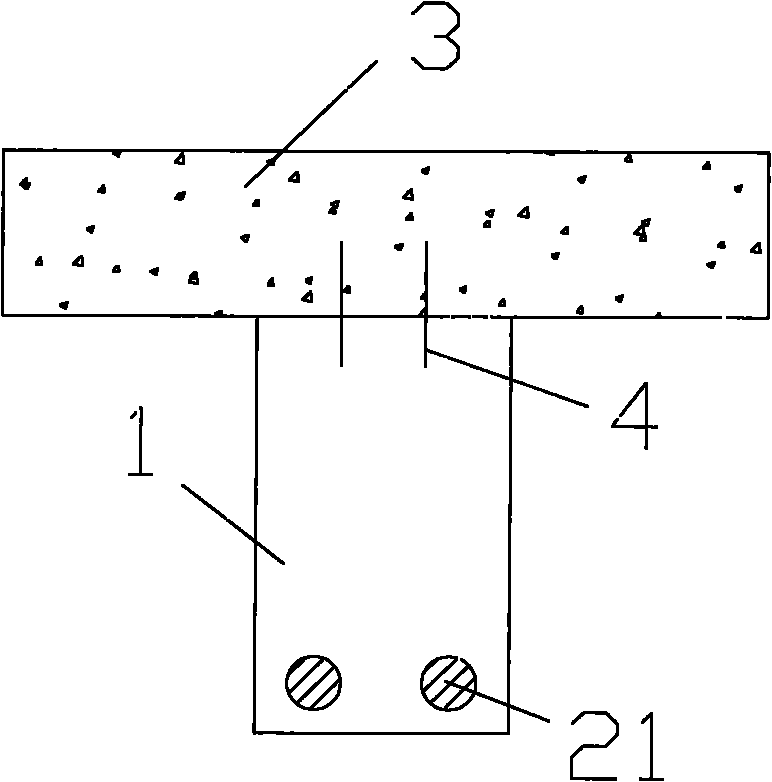

[0032] Such as figure 1 , a FRP-bamboo-concrete composite beam, including bamboo 1, FRP tendon 21, concrete 3 and connector 4 four parts, FRP tendon 21 is located in the middle and lower section of bamboo 1, wrapped by bamboo 1, FRP tendon 21 in The bamboo 1 is implanted into the corresponding position of the bamboo blank before pressing, and the two are bonded together by pressing to form a whole. The concrete 3 is located on the top of the bamboo 1, and its width is greater than or equal to the width of the bamboo 1. The concrete 3 is closely connected with the bamboo 1 through the connector 4.

Embodiment 2

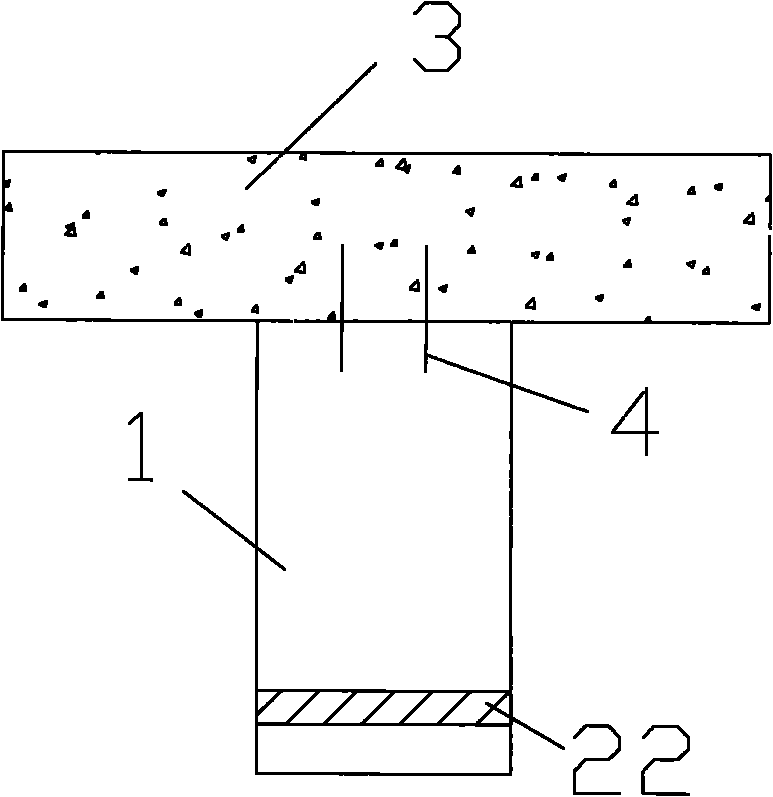

[0034] Such as figure 2 , a kind of FRP-bamboo-concrete composite beam, including bamboo 1, FRP cloth 22, concrete 3 and connector 4 four parts, FRP cloth 22 is located in the middle and lower section of bamboo 1, compounded in the inside of bamboo 1, FRP cloth 22 Before the bamboo material 1 is pressed, it is implanted in the corresponding position of the bamboo blank, and the two are bonded by pressing to form a whole. The concrete 3 is located on the top of the bamboo material 1, and its width is greater than or equal to the width of the bamboo material 1.

Embodiment 3

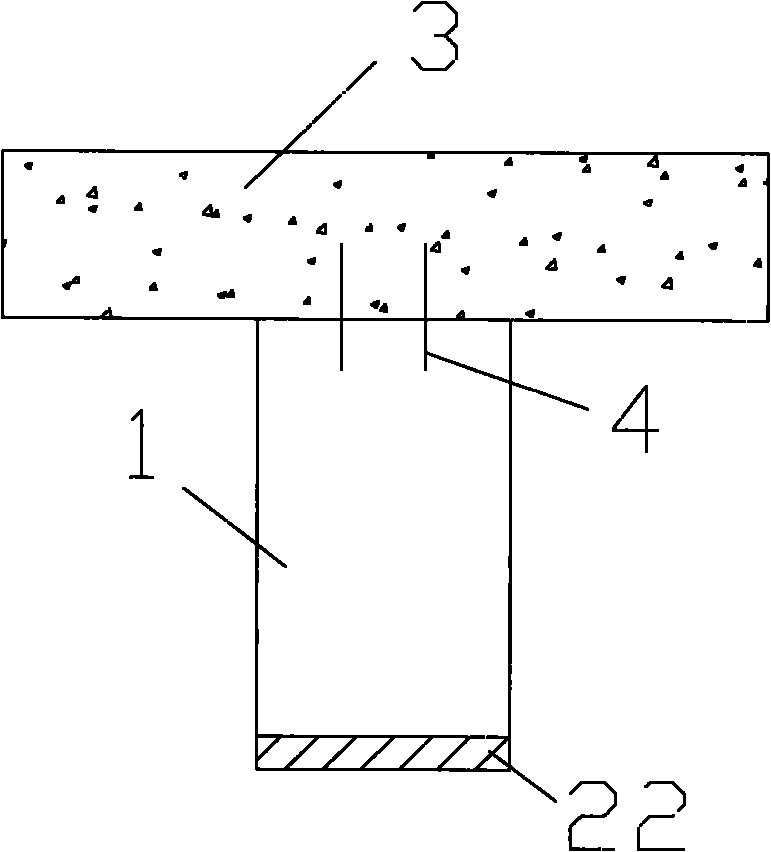

[0036] Such as image 3 , a FRP-bamboo-concrete composite beam, including bamboo 1, FRP cloth 22, concrete 3 and connector 4 four parts, FRP cloth 22 is located at the bottom of the section of bamboo 1, after the bamboo 1 is pressed, add FRP cloth 22 Pressed and pasted on the bottom of the bamboo 1 to form a whole, the concrete 3 is located on the top of the bamboo 1, and its width is greater than or equal to the width of the bamboo 1, and the concrete 3 is closely connected with the bamboo 1 through the connector 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com