Method for determining coal slurry pipeline transportation concentration in coal slurry fluidized bed boiler feeding system

A fluidized bed boiler and pipeline transportation technology, applied in the field of control, can solve problems such as high operating costs, affecting the calorific value of coal slime, and reducing boiler combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

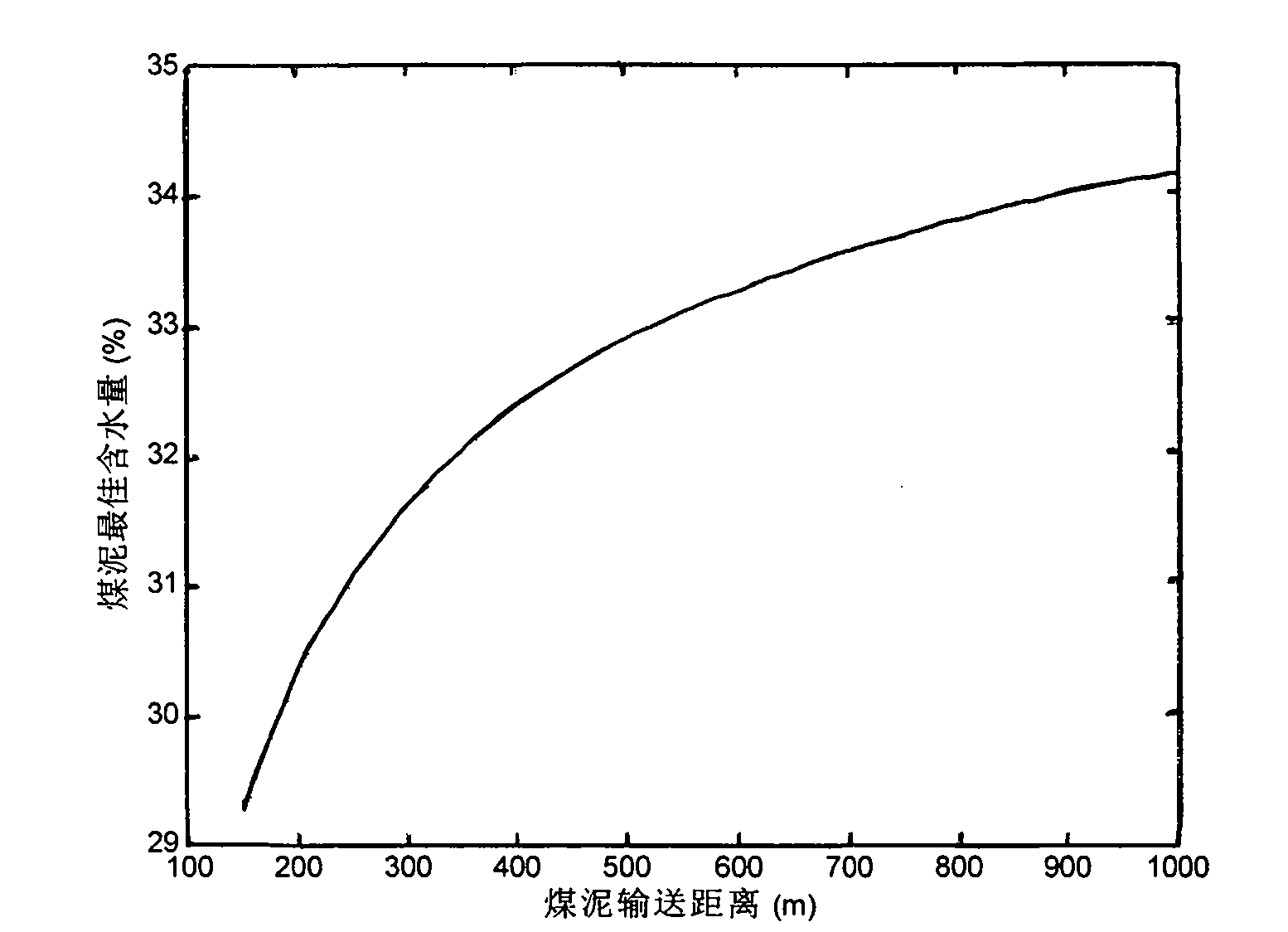

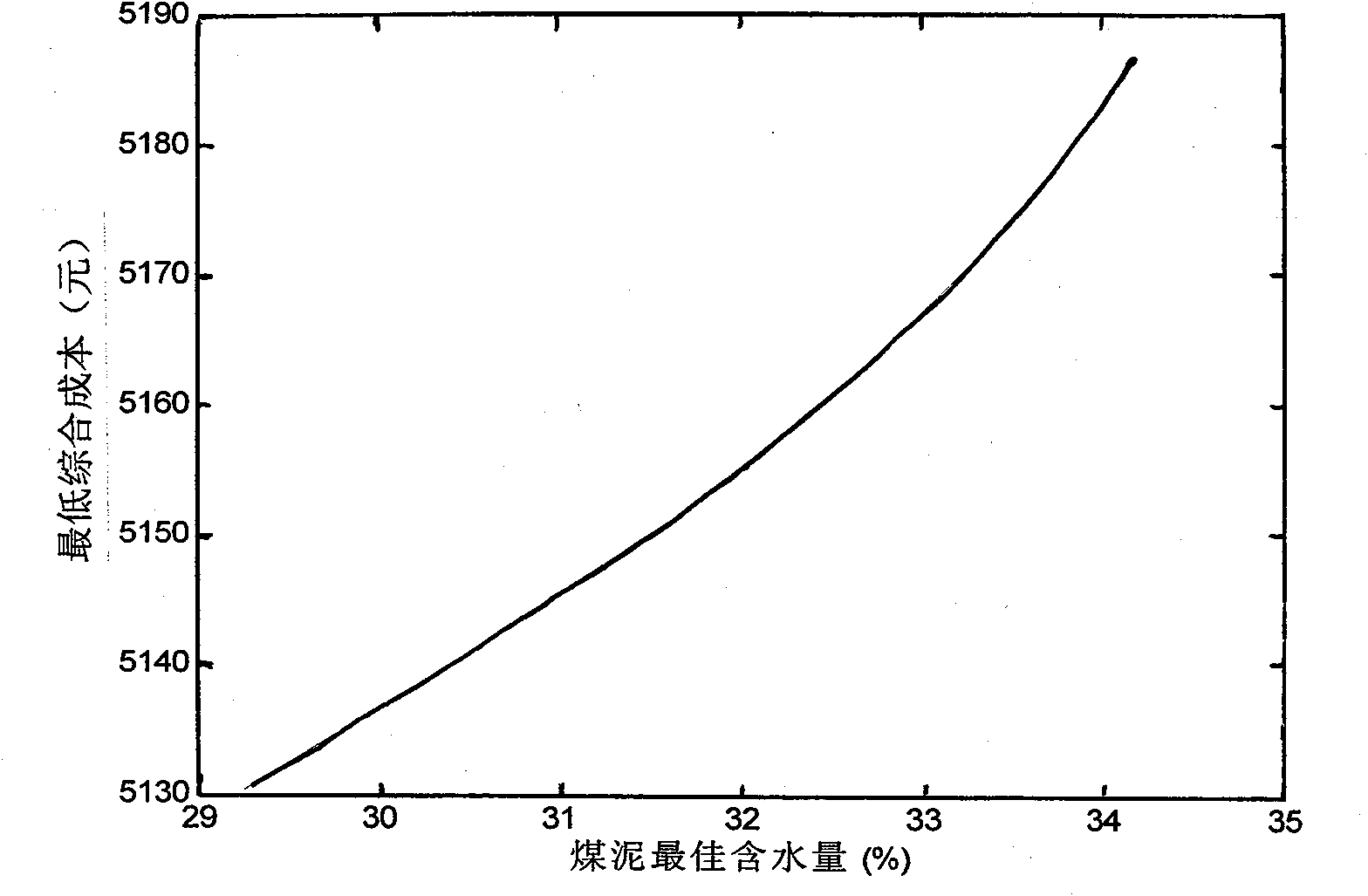

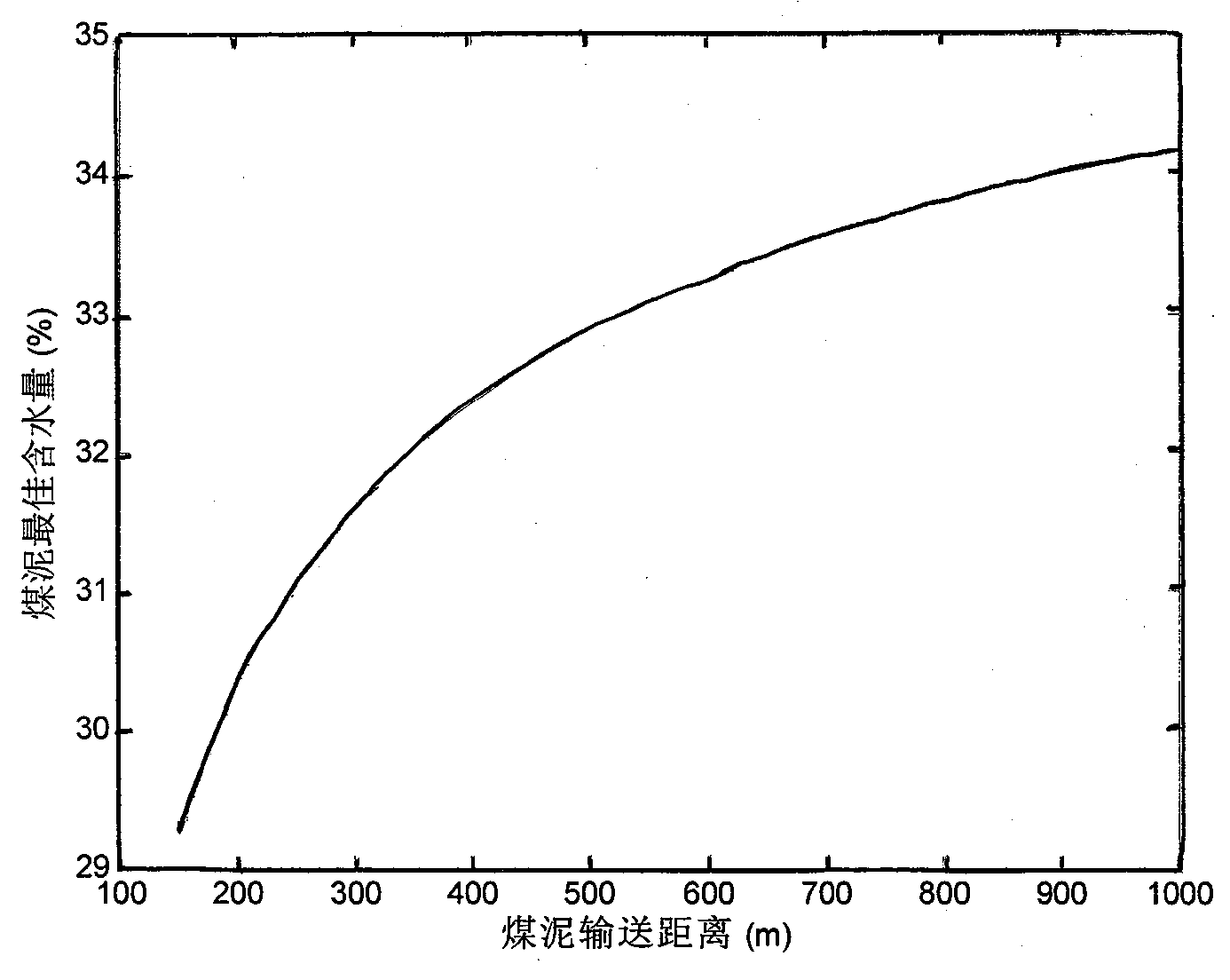

[0048] A method for determining the concentration of coal slime pipeline transport in a coal slime fluidized bed boiler feeding system, the specific steps are as follows:

[0049] Step 1. Establish the pressure loss and power consumption model of coal slime pipeline transportation; coal slime presents typical non-Newtonian fluid characteristics in the process of pipeline wet transportation, and the shear stress τ w with shear rate S w Satisfy:

[0050] τ w = μ dV dy = μS w - - - ( 1 )

[0051] Where V is the slime flow rate, Indicates the velocity gradient, and μ is the apparent viscosity.

[0052] When the slime concentration is high, the rheological properties of the slime conform to the characteristics of yield-pseudoplastic fluid, and its power law constitutive equation is desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com