Preparation method for TiO2 nanometer rod array of dye sensitized solar cell

A technology of solar cells and nanorod arrays, which is applied in the field of preparation of TiO2 nanorod arrays, can solve the problems of large-area uniformity and difficulty in preparation, and achieve the effects of good repeatability, simple equipment, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Preparation method of anatase titanium dioxide nanorods with (220) preferred orientation

[0023] Place a clean ITO conductive glass substrate 70mm above the sputtering target in the vacuum chamber, and control the background vacuum to be less than 1×10 -3 Pa, without additional heating of the substrate.

[0024] Adjust various sputtering process parameters and perform sputtering. Before formal deposition, pre-sputter for 20 minutes. The specific process parameters are:

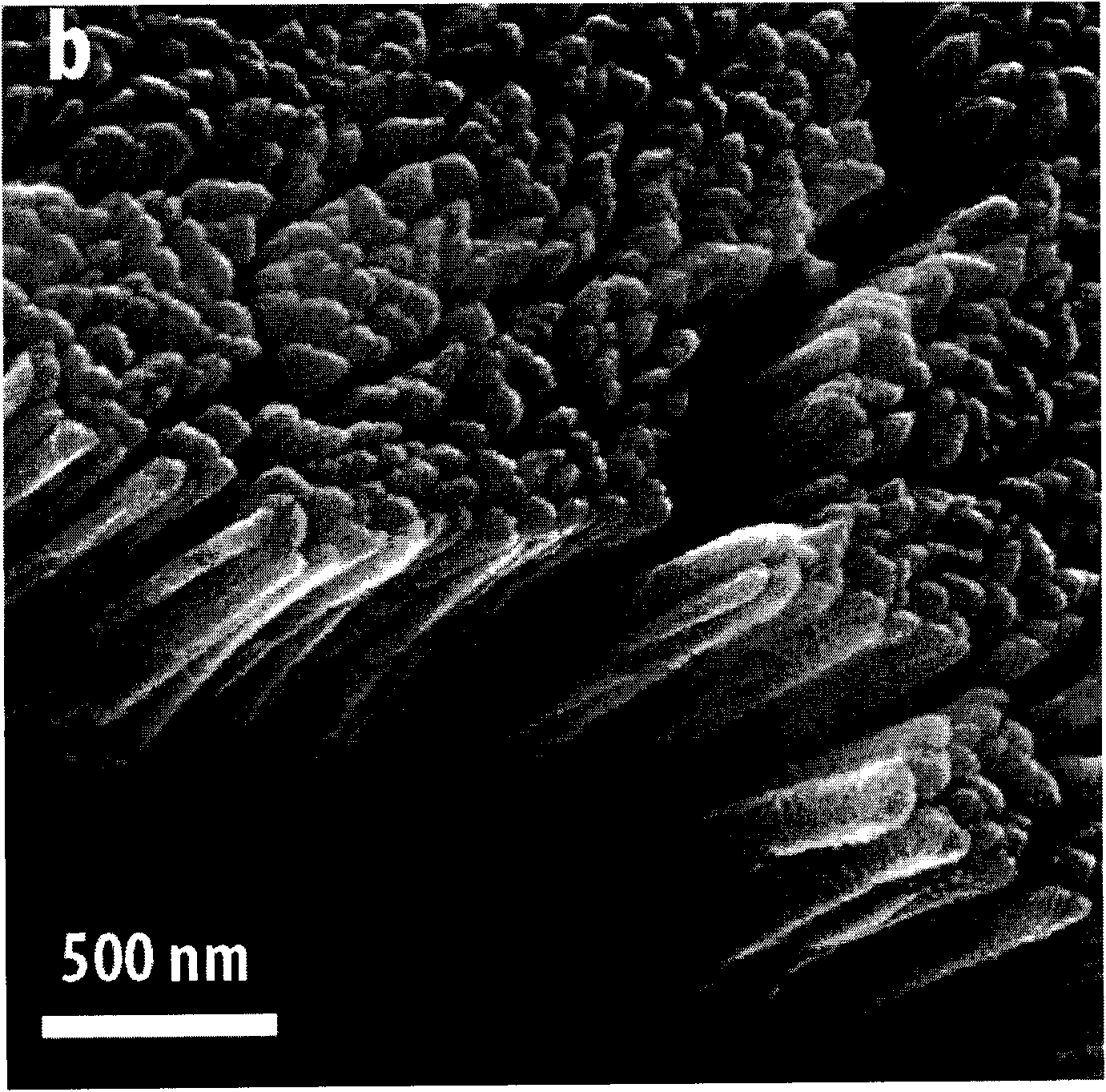

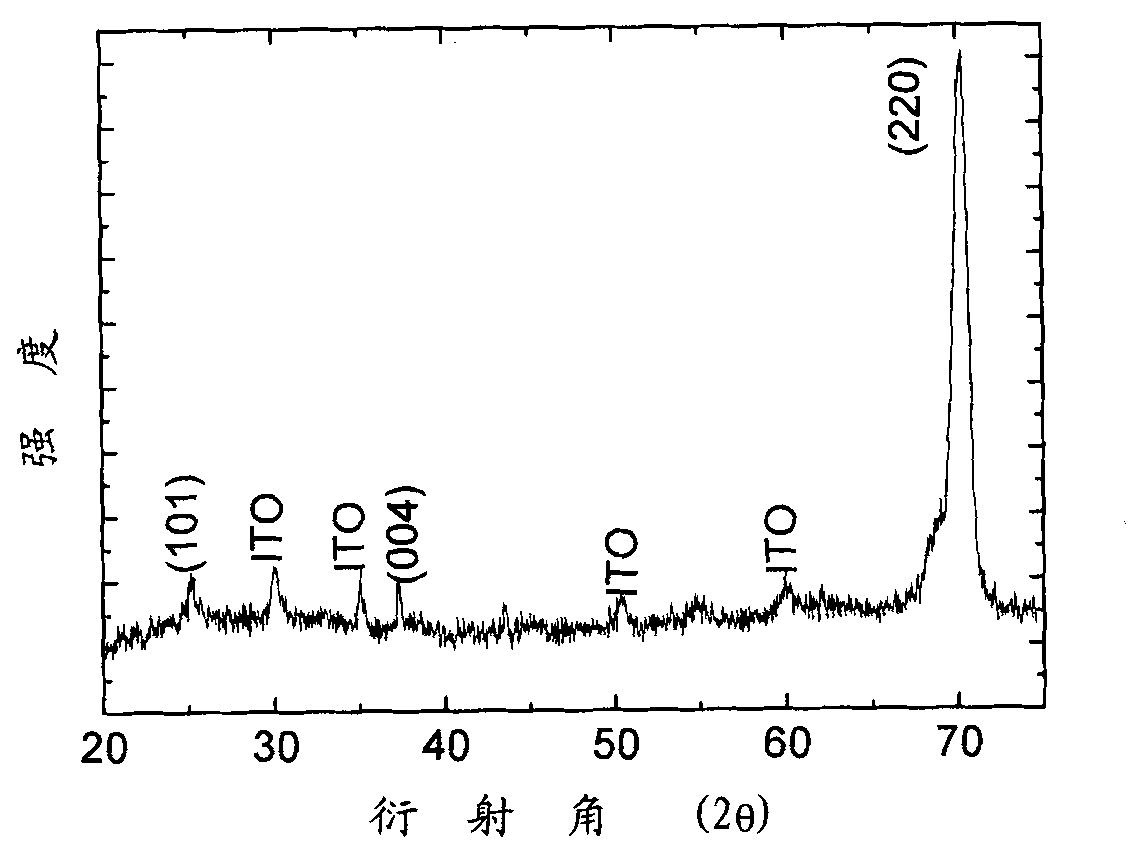

[0025] Reactive gas O 2 The air pressure is 2.5×10 -1 Pa, the pressure of the sputtering gas Ar is 2Pa, the sputtering current is 0.56A, the sputtering power is 235W, the sputtering time is 14 hours, and the TiO with a thickness of about 2 microns is obtained. 2 Nanorod arrays, such as figure 1 shown. Nanorod arrays have a very strong anatase (220) orientation, such as figure 2 shown.

Embodiment 2

[0026] Embodiment 2: the preparation method of the titania nanorod array of different diameters

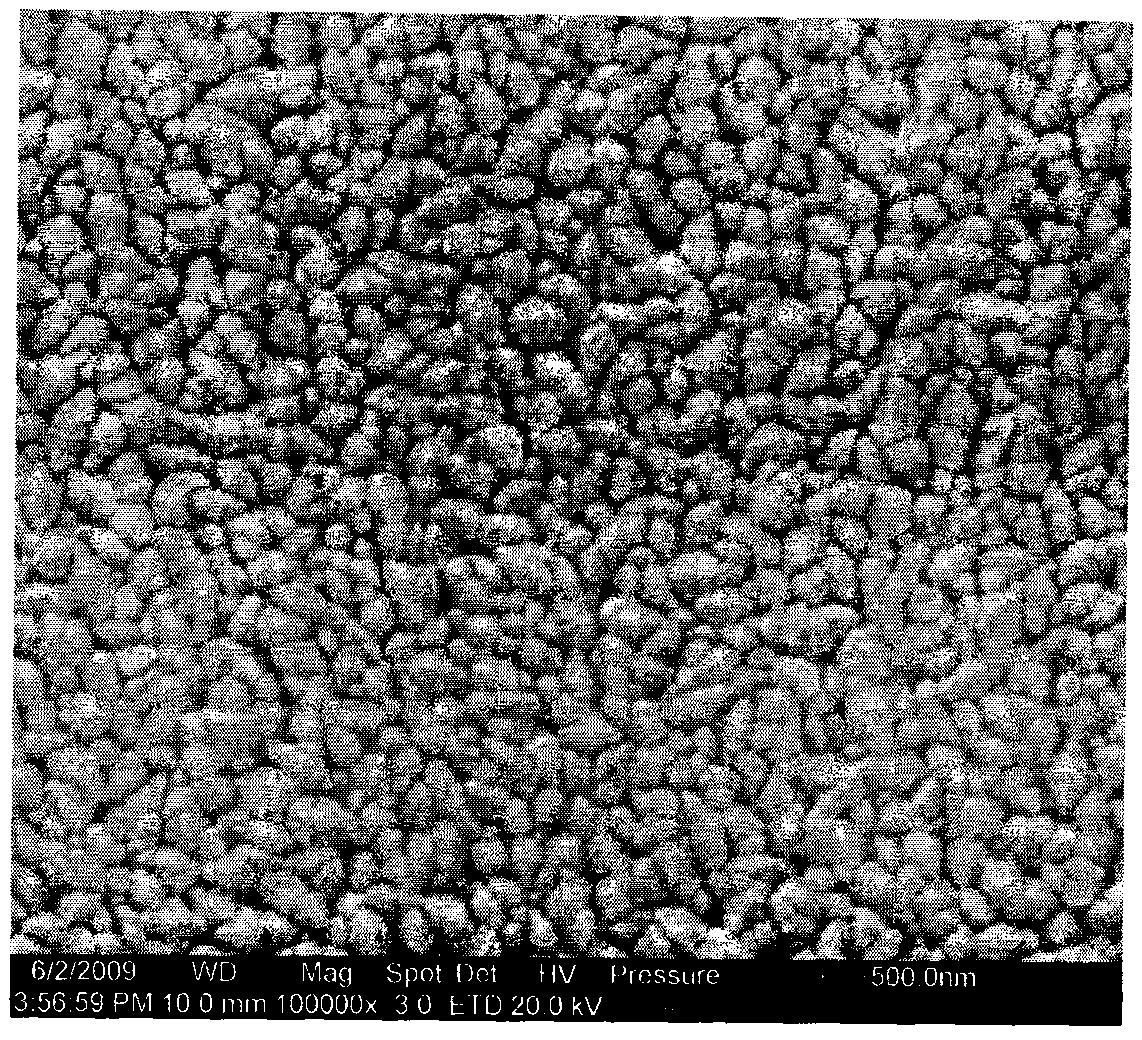

[0027] Change the distance between the target and the substrate from 40mm to 80mm, and other deposition parameters are the same as in Example 1 to obtain TiO with different diameters 2 nanorod arrays. image 3 and Figure 4 are the surface topography photos of the nanorod arrays prepared when the distance between the target substrates is 40 mm and 80 mm, respectively. According to this embodiment, it can be seen that the diameter of the nanorod increases with the shortening of the distance from the target to the substrate, thus providing a method for controlling the diameter of the nanorod.

Embodiment 3

[0028] Example 3: One of the preparation methods of titanium dioxide nanorod arrays with different morphologies

[0029] keep O 2 Air pressure is 3.1×10 -1 Pa, the sputtering current is 0.52A, the distance between the target and the substrate is 50mm, and the pressure of the sputtering pressure is changed from 1Pa to 5Pa, and TiO with different shapes and diameters will be obtained. 2 nanorod arrays. Figure 5 and Figure 6 are the surface morphology of the nanorod arrays prepared when the sputtering pressure is 5Pa and 1Pa, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com