Multifunctional dryer

A drying machine and multi-functional technology, applied in application, food processing, food science, etc., can solve the problems of large space occupation, low thermal efficiency utilization rate, high cost of steam unit, etc., and achieve the effect of simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

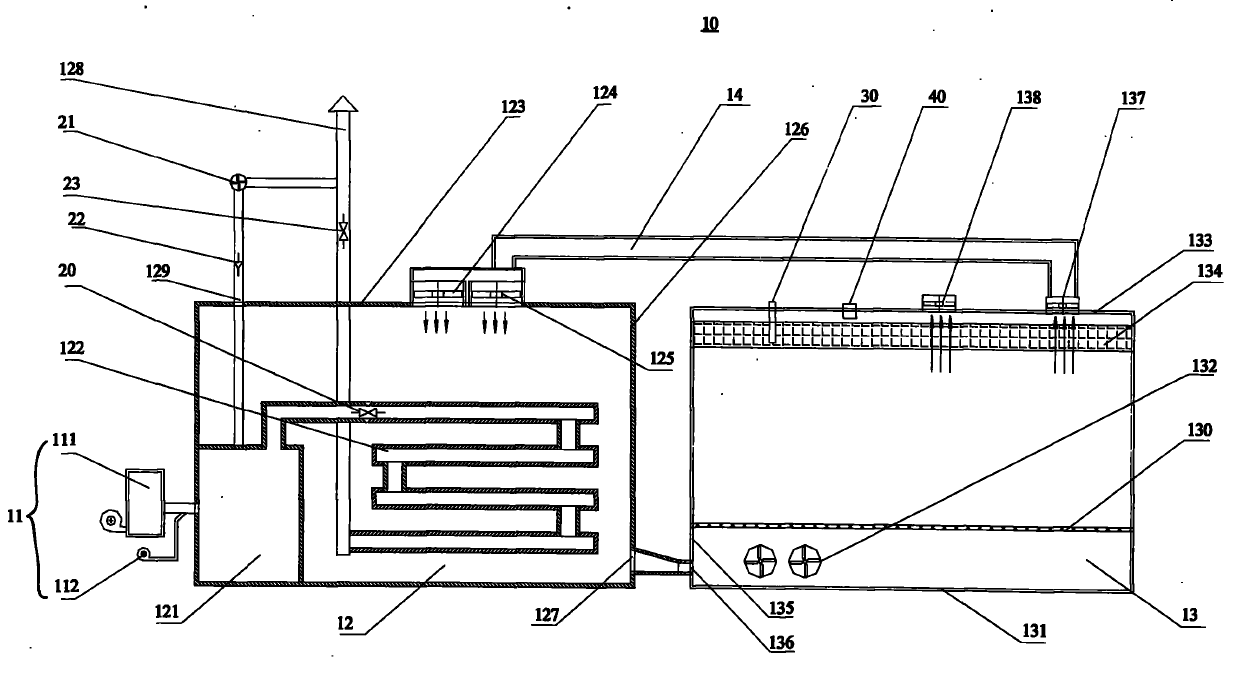

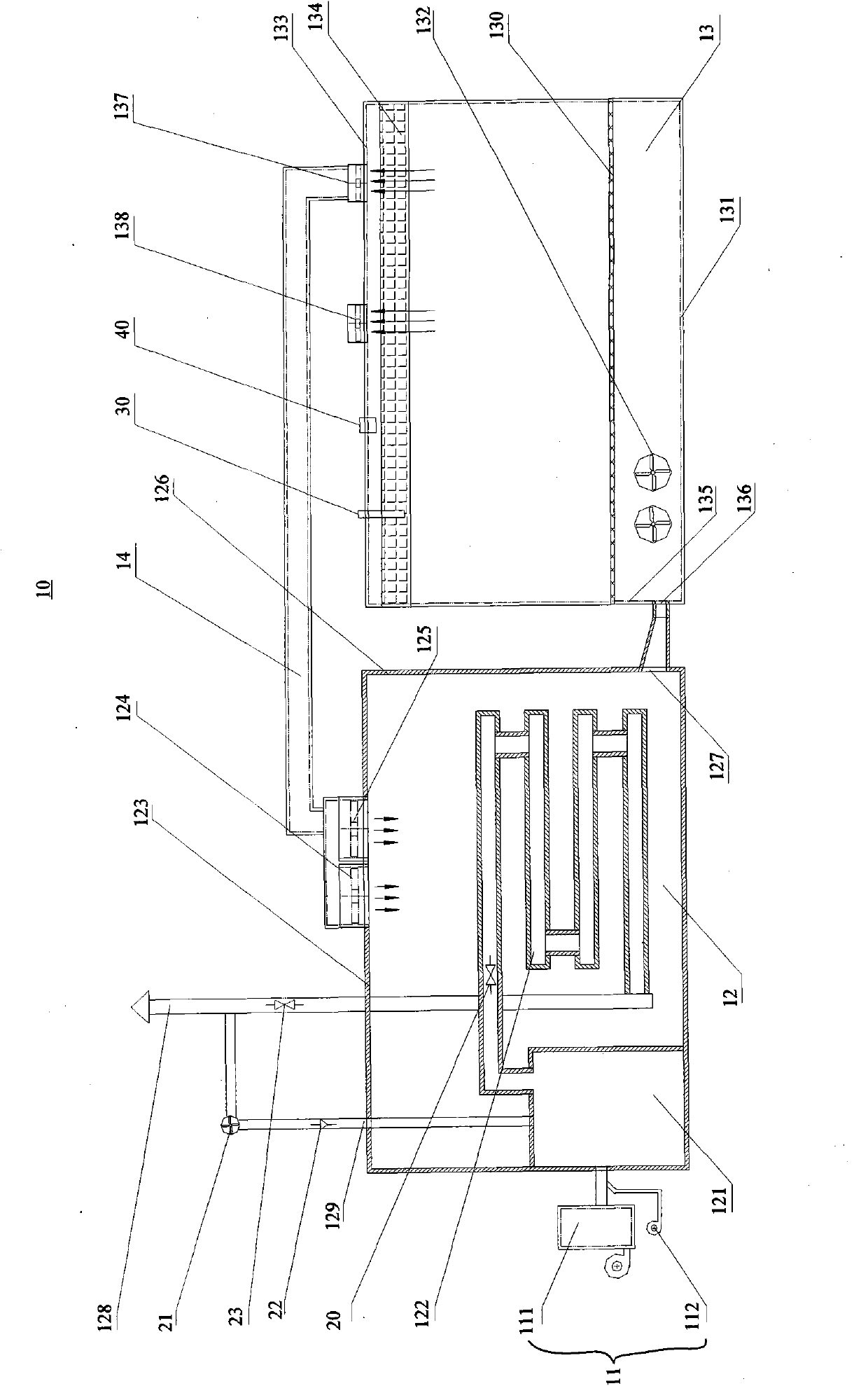

[0008] Please see figure 1 , The multifunctional dryer 10 includes a combustible gas supply device 11 , a hot air chamber 12 , an oven body 13 and a hot air recovery pipe 14 .

[0009] The combustible gas supply device 11 communicates with the hot blast chamber 12 and is used for providing combustible gas to the hot blast chamber 12 . In this embodiment, the combustible gas supply device 11 includes a gas generator 111 and an oxygen pump 112 , the gas generator 111 is used to convert coal into gas, and the oxygen pump 112 is used to supply oxygen to the hot air chamber 12 .

[0010] The hot air chamber 12 is also connected with the oven body 13 for burning combustible gas to generate hot air, and conveying the hot air to the oven body 13 to dry the agricultural products in the oven body 13 .

[0011] The hot air recovery pipe 14 communicates with the hot air chamber 12 and the oven body 13 respectively, and is used to guide the hot air flow in the oven body 13 into the hot ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com