Tire mold low-pressure casting method capable of eliminating deformation of patterned ring

A tire mold and low-pressure casting technology, applied in casting molding equipment, tires, molds, etc., can solve the problems of long casting time, chemical composition deviation, internal structure difference of pattern blocks, etc., and achieve the effect of overall quality improvement and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

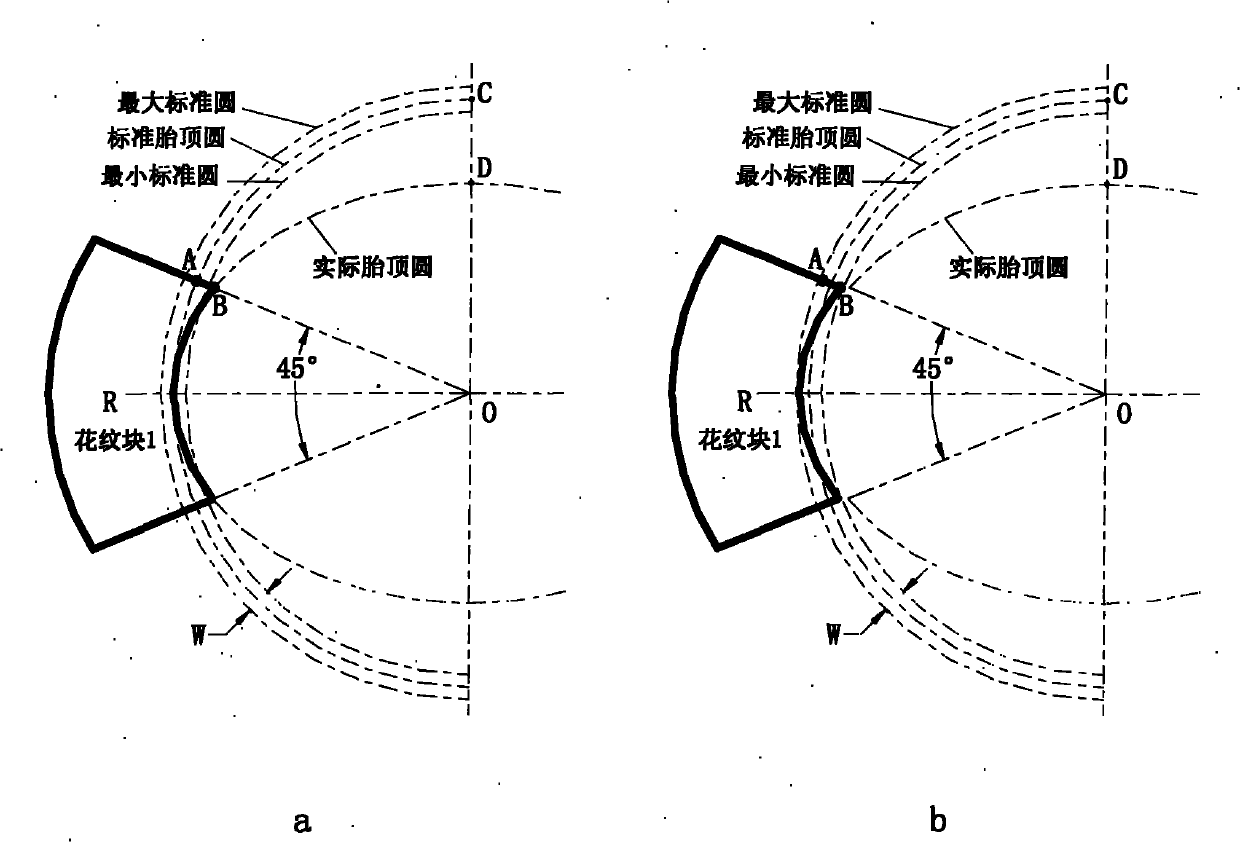

[0013] Do further statement below in conjunction with accompanying drawing:

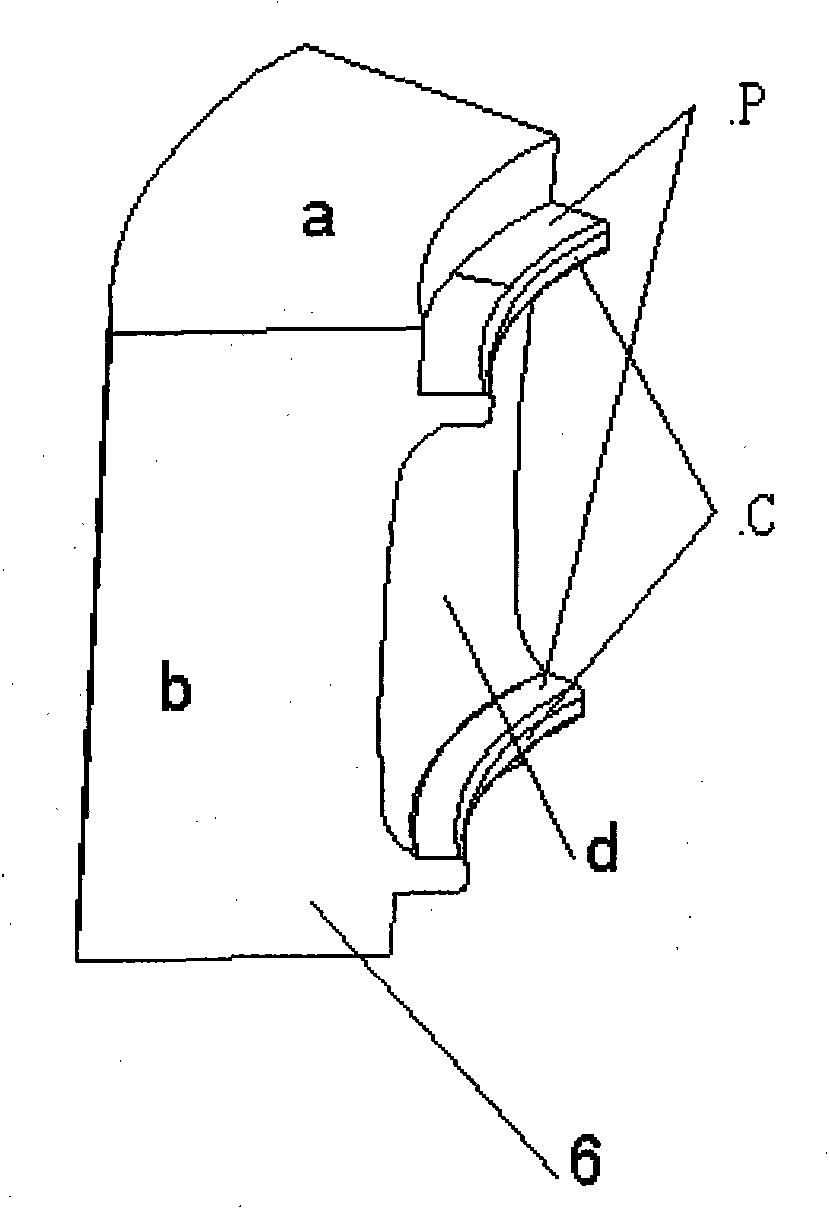

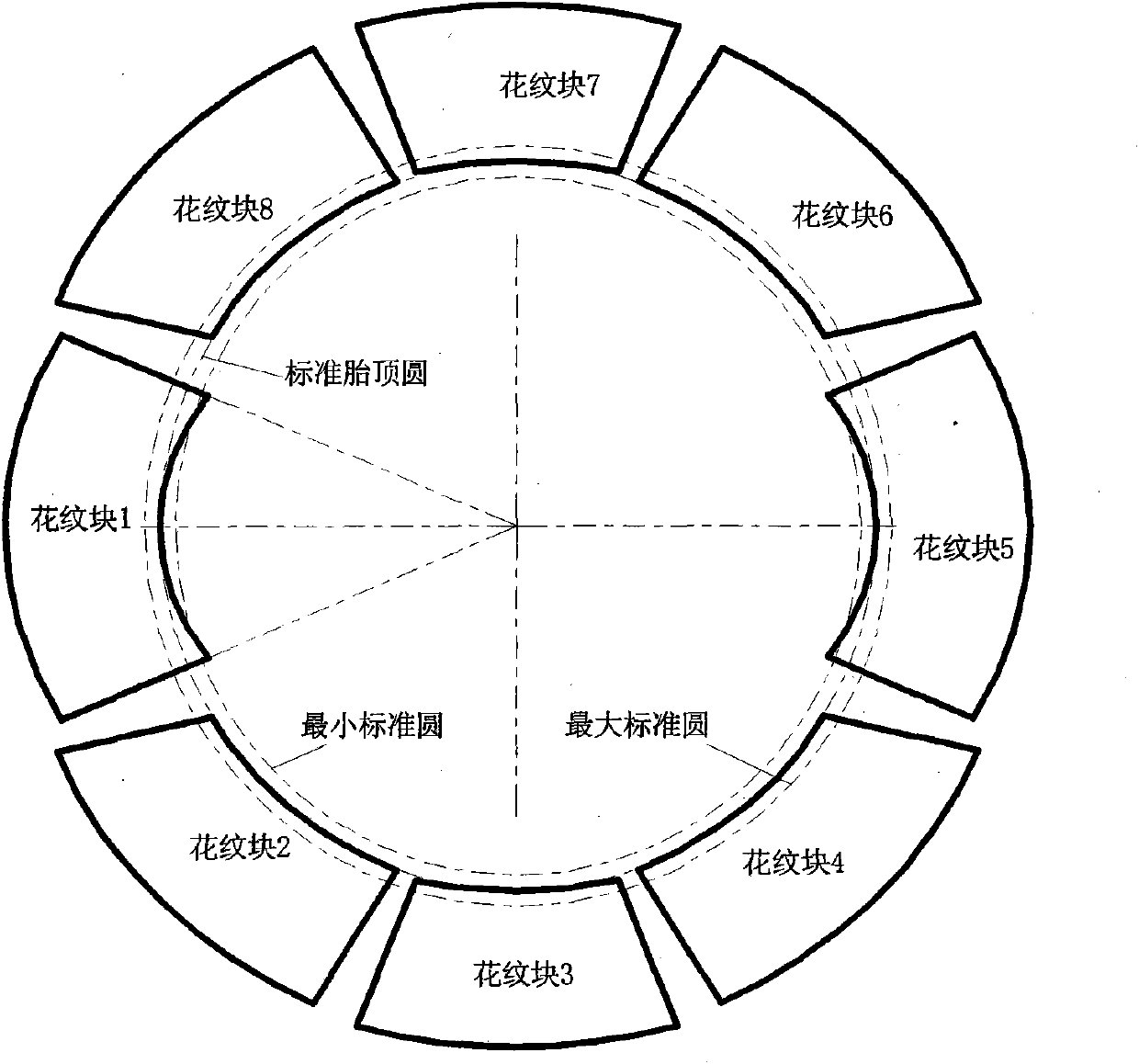

[0014] control figure 1 , when designing the plaster mold first, each piece of plaster mold grows out in advance in the circumferential direction (similar to Figure 5 pattern block), use multiple pieces of draft plaster molds to splice into a plum petal-shaped plaster model 3, and locate it on the lower metal mold 2 of the casting cavity structure; second, process the upper and lower parts of the outer periphery of the plaster model 3 There are upper and lower horizontal positioning grooves with coaxial centers; thirdly, install the upper metal mold 1 on the outer periphery of the plaster model, and the plaster mold is used as the core mold and the upper and lower metal molds to form the casting cavity, and the liquid aluminum After filling the casting cavity along the lower metal mold runner 5, solidify into an aluminum alloy tire mold casting (the middle part is blocked by a gypsum board 4); four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com