Organic/inorganic salt and alkali resistant long-acting corn fertilizer

A special corn fertilizer and saline-alkali resistance technology, applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems of soil aggregate structure damage, increase farmers' labor intensity, and aggravate soil compaction, so as to promote the formation of soil aggregate structure, Improve soil permeability and increase organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred formula of organic and inorganic saline-alkali-resistant long-acting corn special fertilizer of the present invention is as follows: select nitrogen 18%, phosphorus 6%, potassium 6%, sulfur 20%, amino acid 4%, organic matter 10%, humic acid 5%, medium and trace elements 5% %, long-acting agent 1%, then add 25% clay, mechanically mix and then granulate.

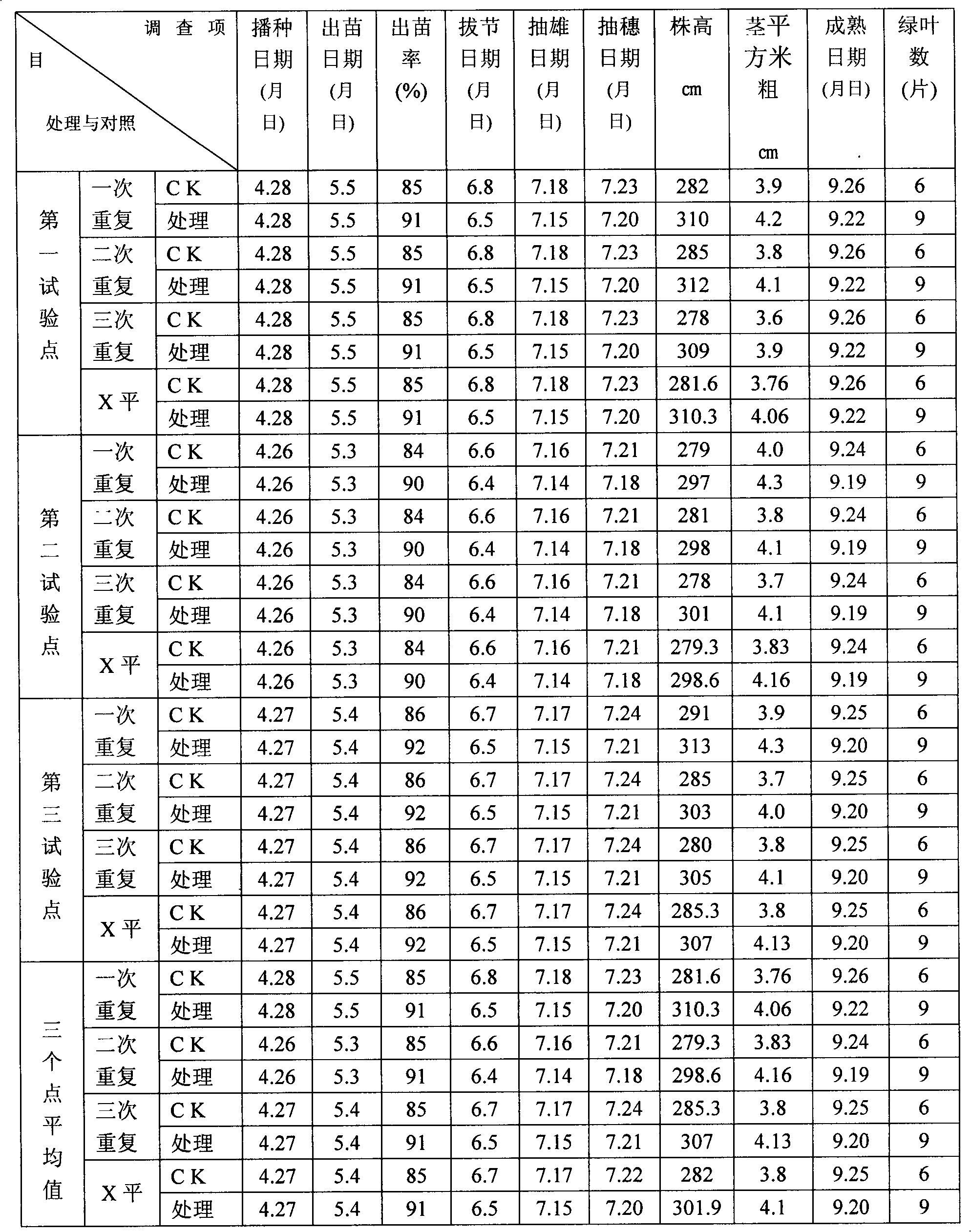

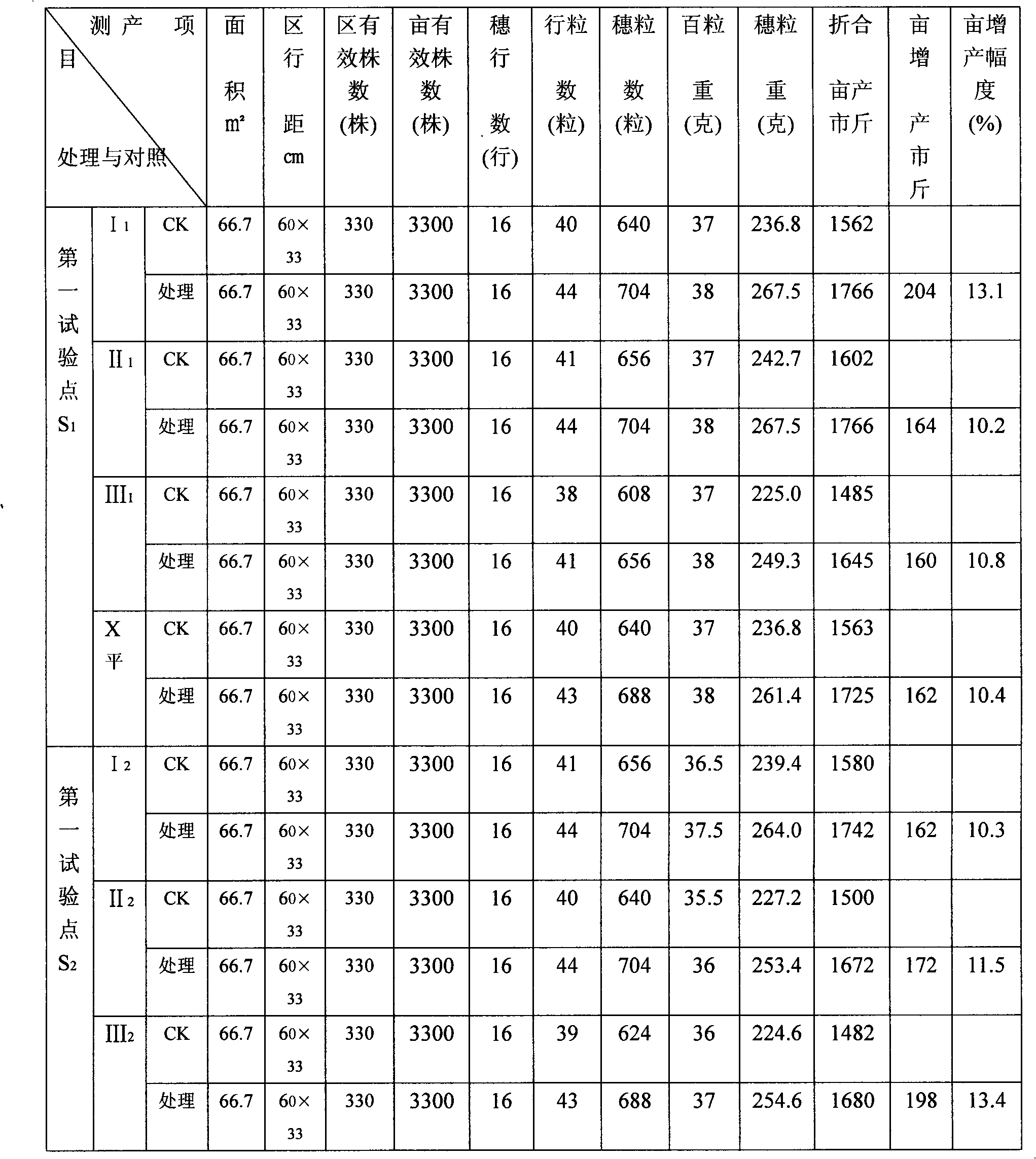

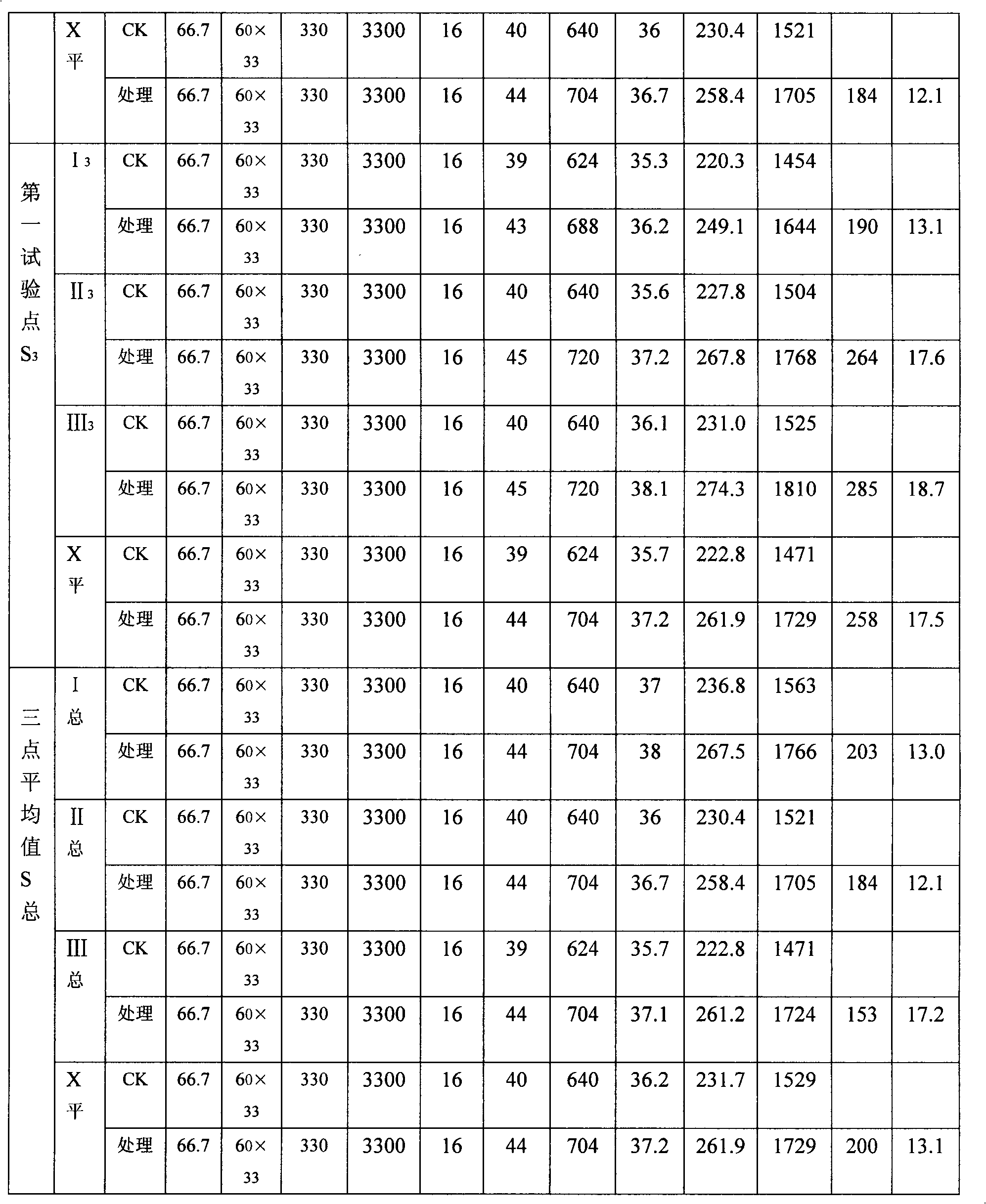

[0017] Regional control test, this test is respectively in three different regions, adopts conventional fertilization method respectively as contrast field and organic and inorganic saline-alkali resistant long-acting corn special fertilizer of the present invention, two processes, adopt three times repetition method, after autumn, single harvest and single plant, Finally, carry out the statistics and take the average value to calculate the production.

[0018] 1. Processing

[0019] The plot area is 33.3 square meters for each treatment, 66.6 square meters for one treatment, repeated three times, 199.8 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com