Mixed fluorescent powder matched with blue-light chip and preparation method thereof

A blue light chip and phosphor technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of products not conforming to color temperature and color rendering index, affecting the consistency of LED products, and inaccurate mixed phosphors, etc. In large-scale industrial production, the color rendering index is improved, and the quantum efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of the mixed phosphor used in conjunction with the blue light chip includes the following steps:

[0030] Red Phosphor A 1-x B y o z N 2 / 3+4 / 3y-2 / 3z :xRe and yellow phosphor Y 3-a-b A l5 Ba a o 12 : Ce b 3+ According to the mass ratio of 50:100, after mixing evenly in ethanol with 2 times the mass of yellow fluorescent powder, stir under ultrasonic vibration, heat to 150°C and keep for 0.5h; then add polyvinyl alcohol with 5 times the mass of yellow fluorescent powder, 5 times the polyacrylamide, after it is completely dissolved, it is fully stirred evenly to form a gel-like mixture, and the mixed phosphor used in conjunction with the blue-ray chip is obtained.

Embodiment 2

[0032] The preparation of the mixed phosphor used in conjunction with the blue light chip includes the following steps:

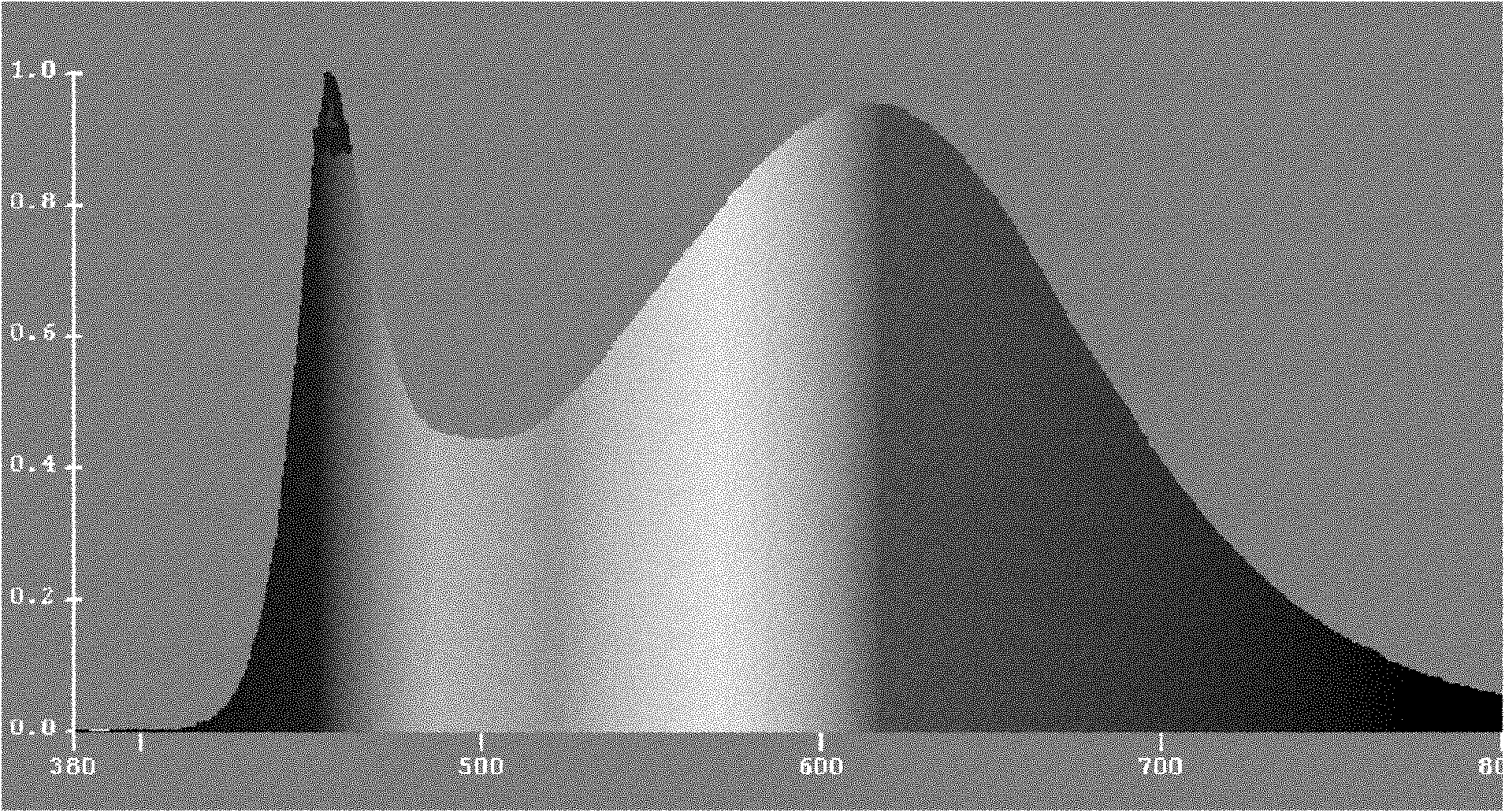

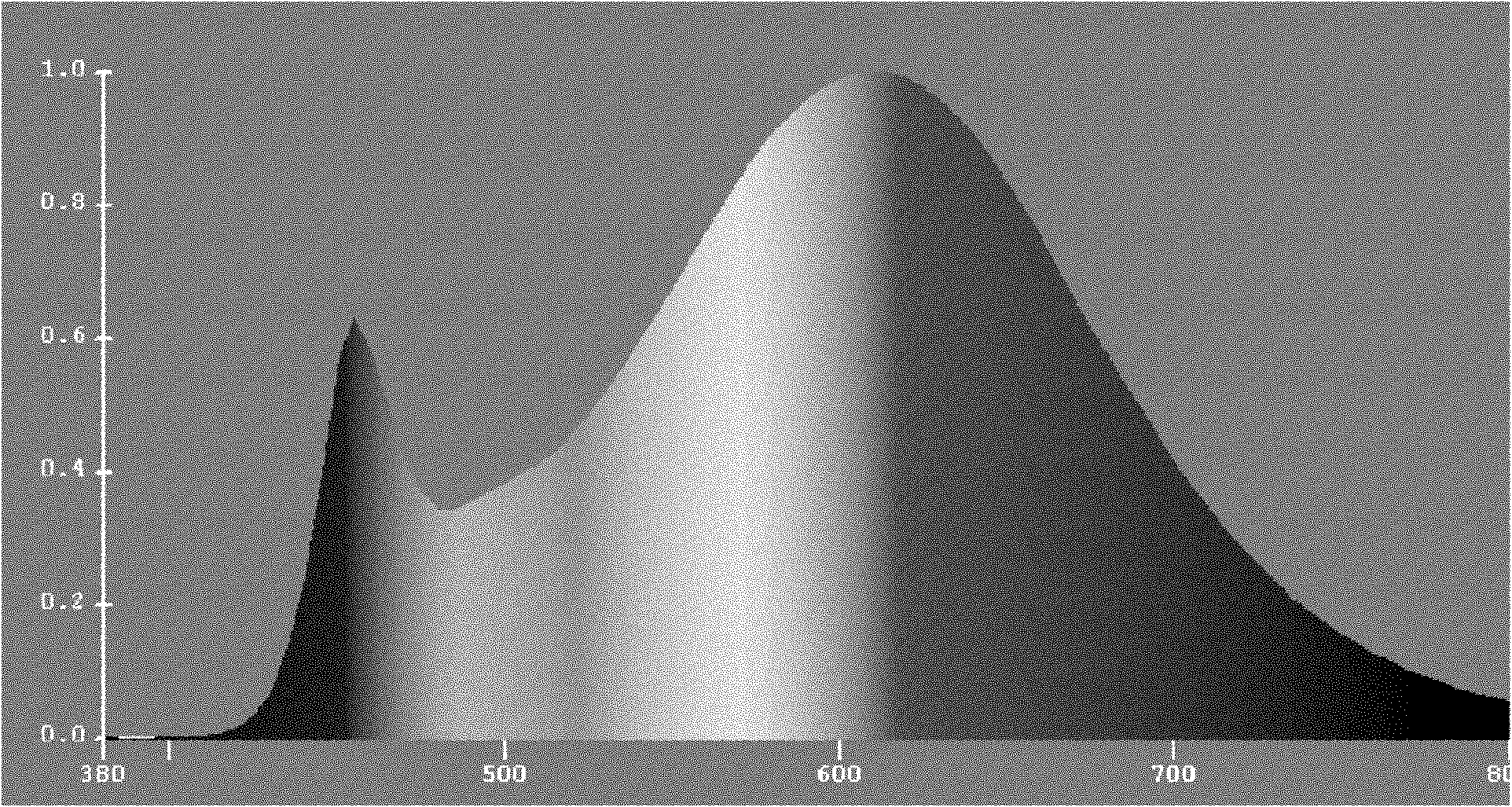

[0033] Test two kinds of fluorescent pink phosphor A separately 1-x B y o z N2 / 3+4 / 3y-2 / 3z :xRe, yellow phosphor Y 3-a-b Al 5 Ba a o 12 : Ce b 3+ The color coordinates and emission wavelength, the screening color coordinates are: 0.427≤X≤0.437, 0.537≤Y≤0.547, the yellow phosphor powder whose emission wavelength is 550≤λ≤560 after being excited by blue light; the screening color coordinates are: 0.630≤X ≤0.640, 0.360≤Y≤0.370, red phosphor with an emission wavelength of 615≤λ≤625 after being excited by blue light;

[0034] Mix the screened red phosphor and yellow phosphor in a mass ratio of 38:100 in ethanol that is 5 times the mass of the yellow phosphor, stir under ultrasonic vibration, heat to 100°C, and keep for 1 hour; then add yellow phosphor 6 times the polyvinyl alcohol and 6 times the polyacrylamide in the powder mass, after they are complet...

Embodiment 3

[0036] The preparation of the mixed phosphor used in conjunction with the blue light chip includes the following steps:

[0037] Red Phosphor A 1-x B y o z N 2 / 3+4 / 3y-2 / 3z :xRe, yellow phosphor Y 3-a-b Al 5 Ba a o 12 : Ce b 3+ The screening is identical with embodiment 2;

[0038] Mix the screened red phosphor and yellow phosphor in a mass ratio of 45:100 in ethanol that is 6 times the mass of the yellow phosphor, stir under ultrasonic vibration, heat to 120°C, and keep for 0.8h; then add yellow After the polyvinyl alcohol with 8 times the mass of the phosphor powder and the polyacrylamide with 10 times the mass are completely dissolved, they are fully stirred evenly to form a gel-like mixture, and the mixed phosphor powder used in conjunction with the blue-ray chip is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com