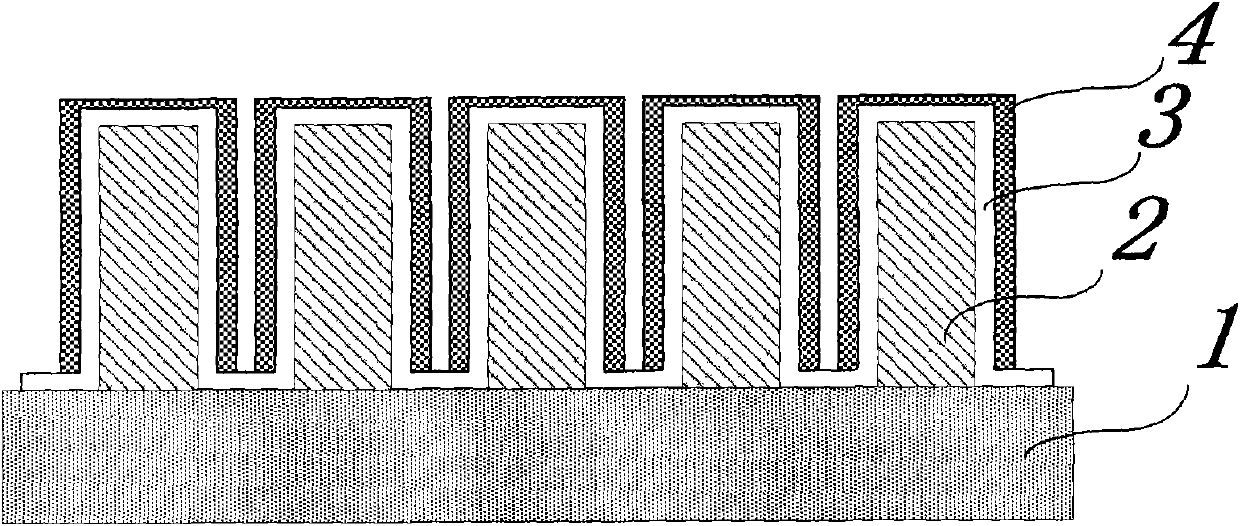

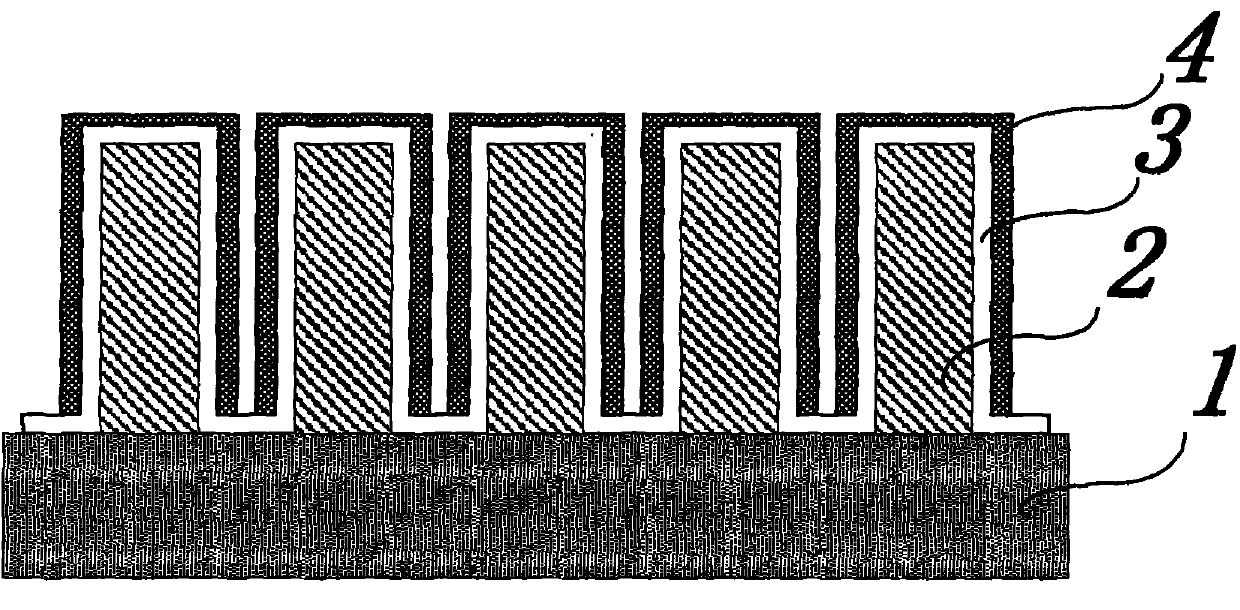

Polypyrrole microelectrode with three-dimensional structure and preparation method thereof

A technology of three-dimensional structure and manufacturing method, which is applied in circuits, capacitors, electrical components, etc., to achieve the effects of improving storage capacity, improving high-current discharge characteristics, and improving energy storage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

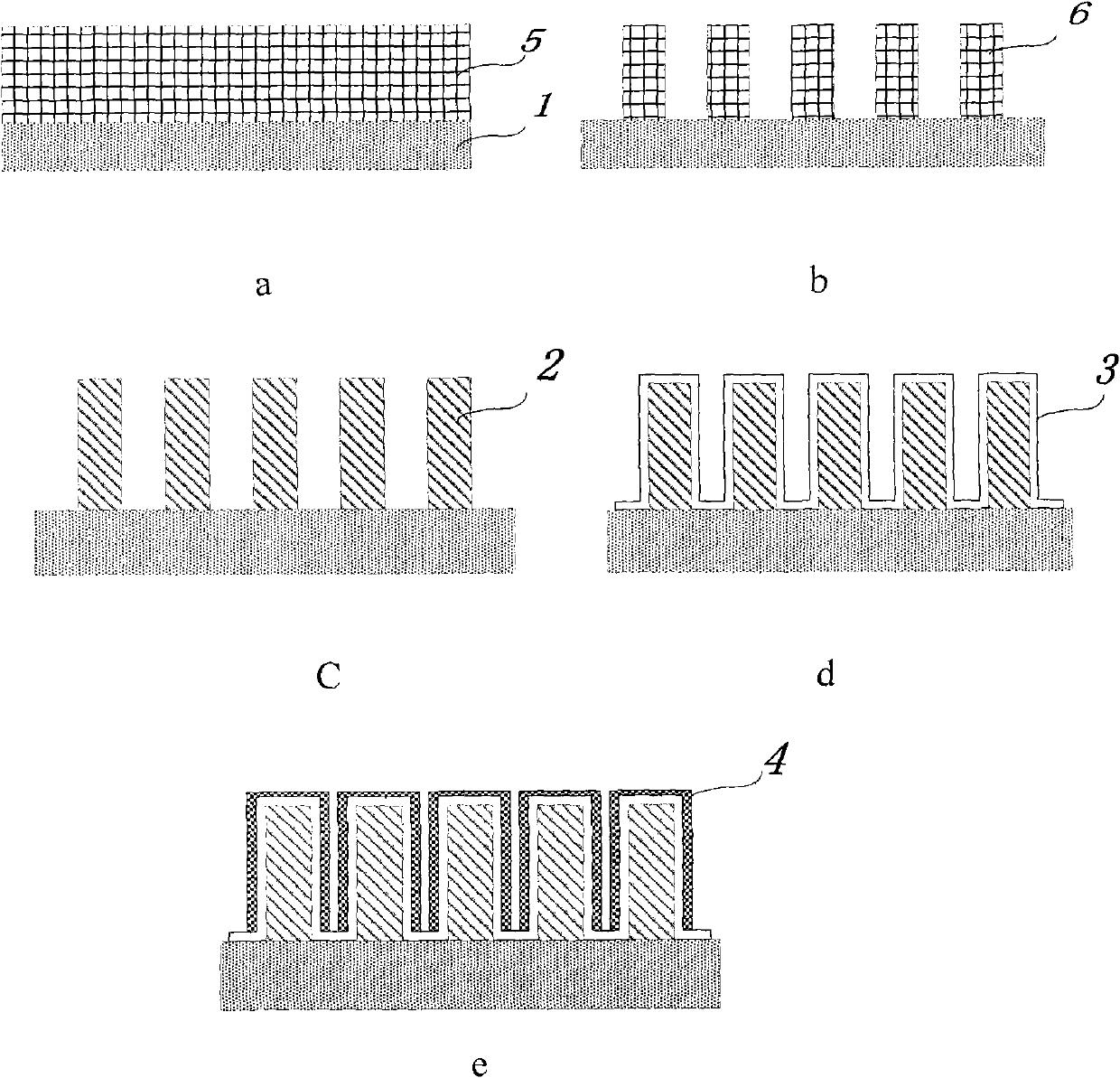

Embodiment

[0026] Select the SU-8 100 specification model (product of Micro Chem Corp., USA) in the SU8 epoxy-based negative chemical amplification glue to carry out the glue-spinning process on the copper metal substrate to prepare the SU-8 glue film layer with uniform thickness. Put the SU-8 glue in an ultrasonic (frequency 33KHz) constant temperature bath, keep the temperature at 25°C, and vibrate ultrasonically for 30 minutes under the condition of a lower power of 50W to reduce the viscosity of the SU-8 glue and remove most of the gas in the glue.

[0027] Fix the copper metal substrate on the platform of the gluing machine, drop an appropriate amount of the above-mentioned SU-8 glue on the substrate, and uniformly accelerate the substrate speed from static to a certain low speed, the speed is 500 rpm, and maintain it for 5 seconds; Then evenly accelerate to a higher speed, the speed is 2000 rpm, maintain for 15 seconds, and then evenly decelerate to a standstill. The finished subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com