Structure of P-type GaN layer of GaN-based light-emitting diode chip

A technology of dies and holes, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of implanting plasmonic systems and limited distance of coupling enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

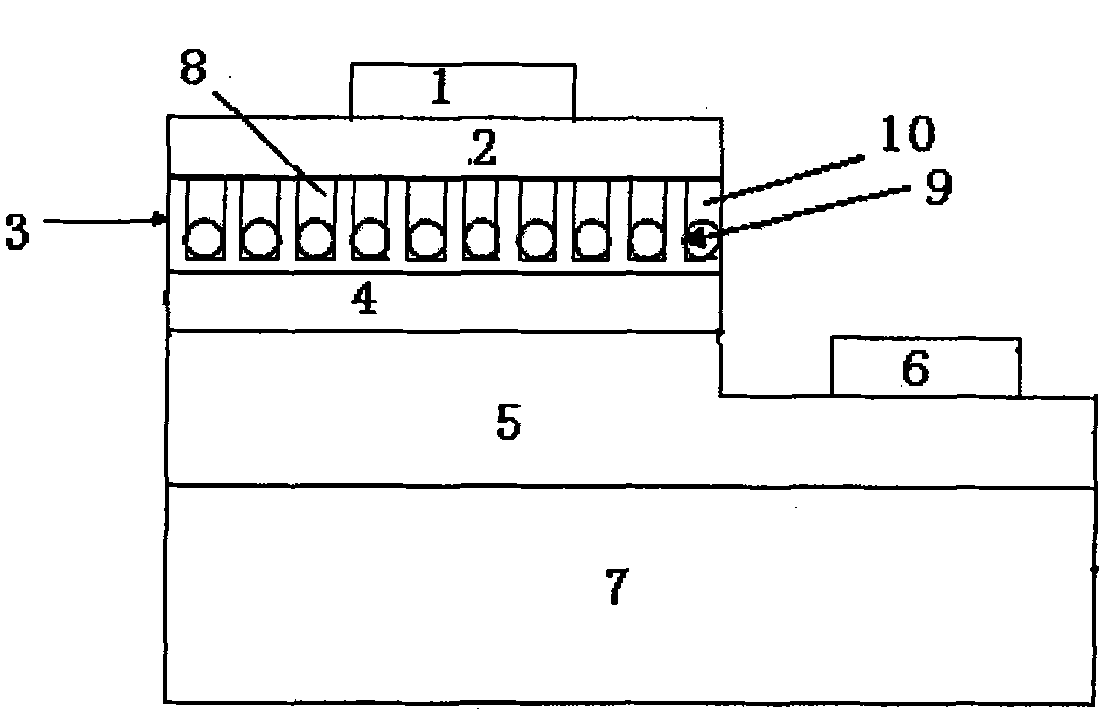

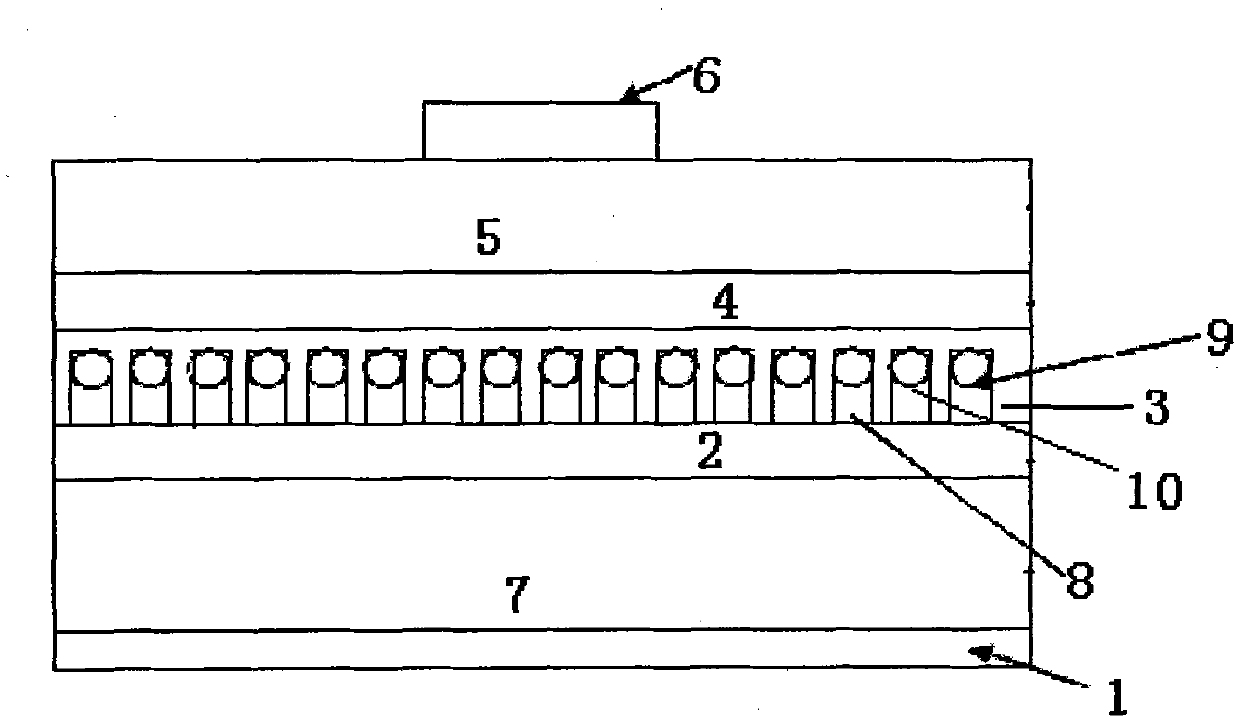

[0018] The structure of the P-type GaN layer on the conventional GaN-based LED tube core of the present invention, such as figure 1 shown. The die structure of a conventional GaN-based LED includes a P electrode 1, a P surface contact current spreading layer 2, a P-GaN layer 3, a quantum well active region 4, an N-GaN layer 5, an N electrode 6 and a substrate from top to bottom. Bottom 7. In the present invention, holes 8 with a diameter of 50 nanometers to 1000 nanometers are arranged on the P-GaN layer 3, and the distance between the holes is 0.1 micrometers to 10 micrometers. The distance between the bottom of the hole 8 and the quantum well active region 4 adjacent to the P-GaN layer 3 is 10 nanometers to 100 nanometers. The holes 8 are filled with metal particles 9 with a thickness of 10 nm to 400 nm, and the particle diameter of the metal particles 9 is 5 nm to 100 nm. The metal particles 9 are metal particles such as metal Ag, Al, Ni or Au, which can be obtained by t...

Embodiment 2

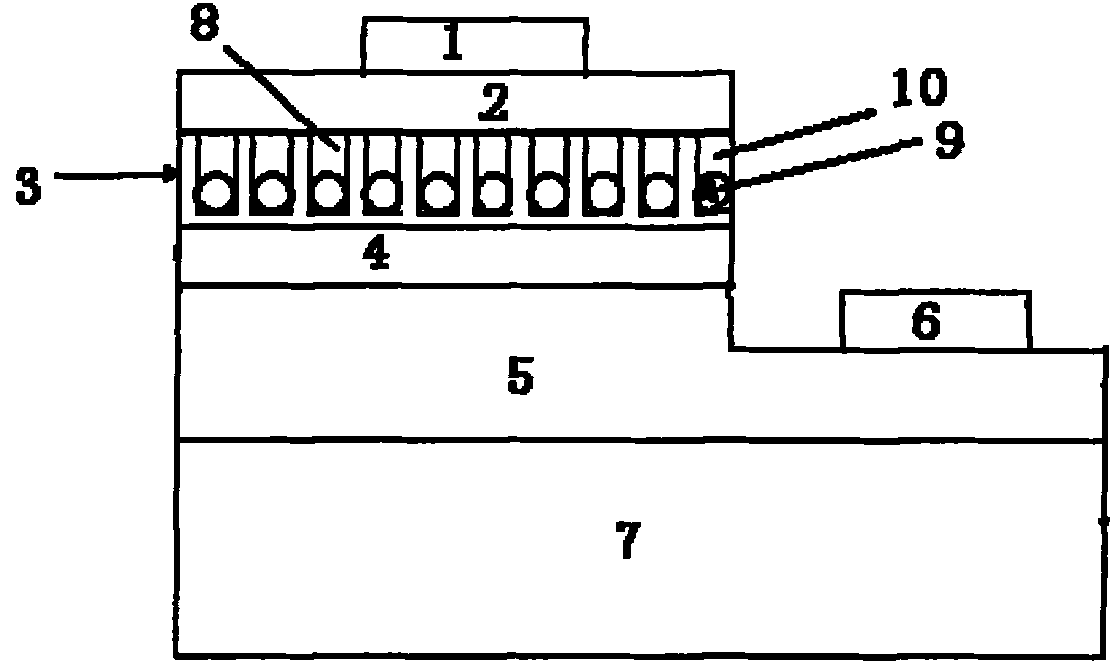

[0021] This embodiment is applied to a GaN-based LED tube core structure with a vertical flip-chip structure, such as figure 2 shown. The structure of the P-GaN layer on it is the same as that of the P-type GaN layer on the conventional GaN-based LED tube core in Example 1. The epitaxial layer is transferred to other substrates by flip-chip technology, and a high-power vertical structure chip can be produced. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com