High pressure pulse modulator and modulation method thereof for steep falling edge and low power consumption plasma immersion ion implantation

A technology of high-voltage pulse modulation and plasma immersion, applied in the direction of conversion equipment without intermediate conversion to AC, can solve the problem of long falling edge of output pulse, achieve the effect of short falling edge of waveform, improve power supply efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

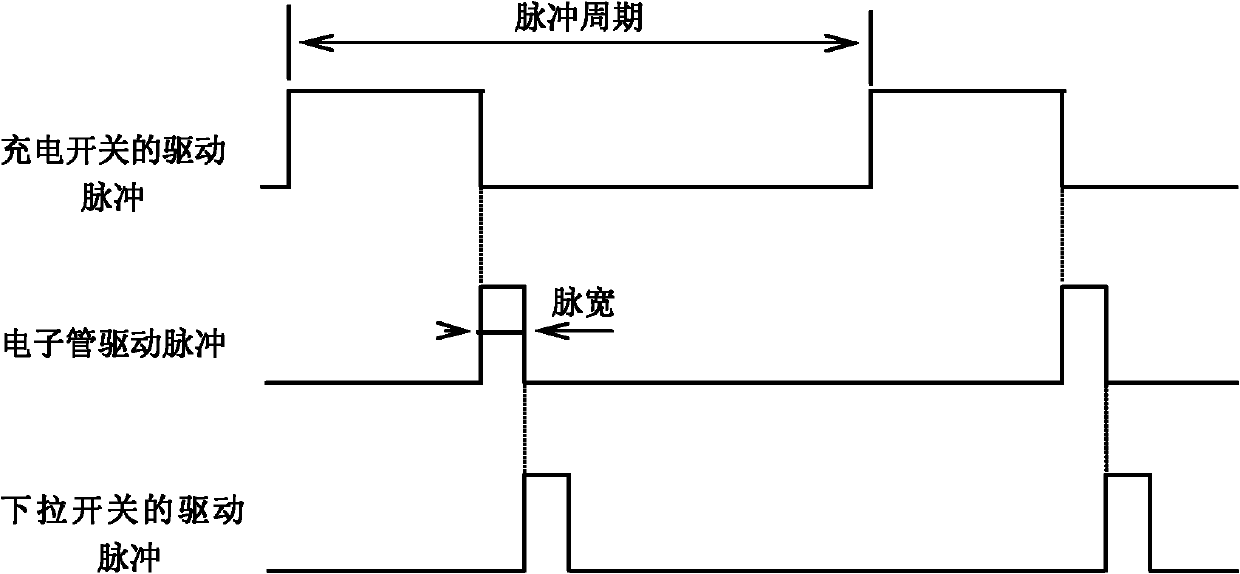

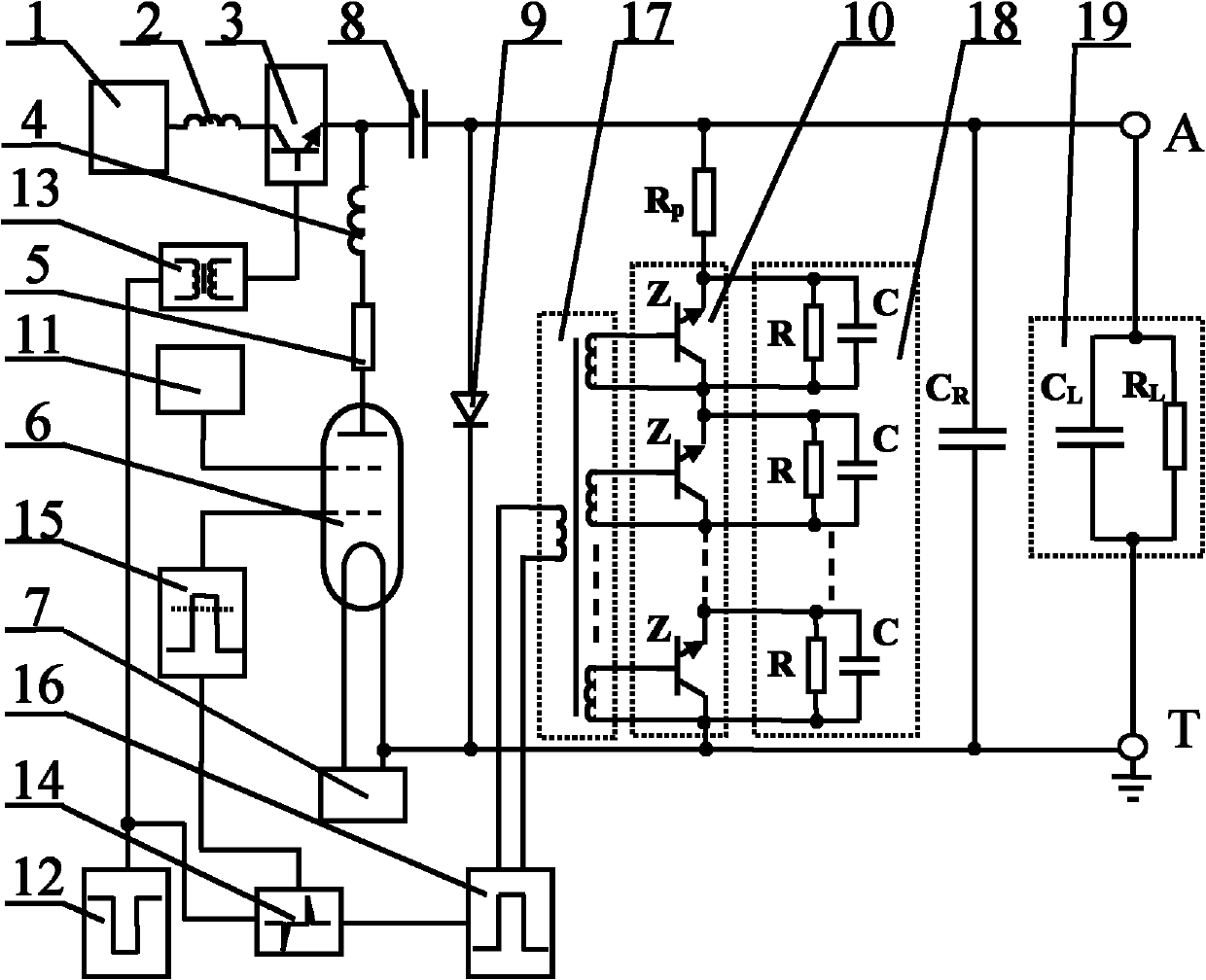

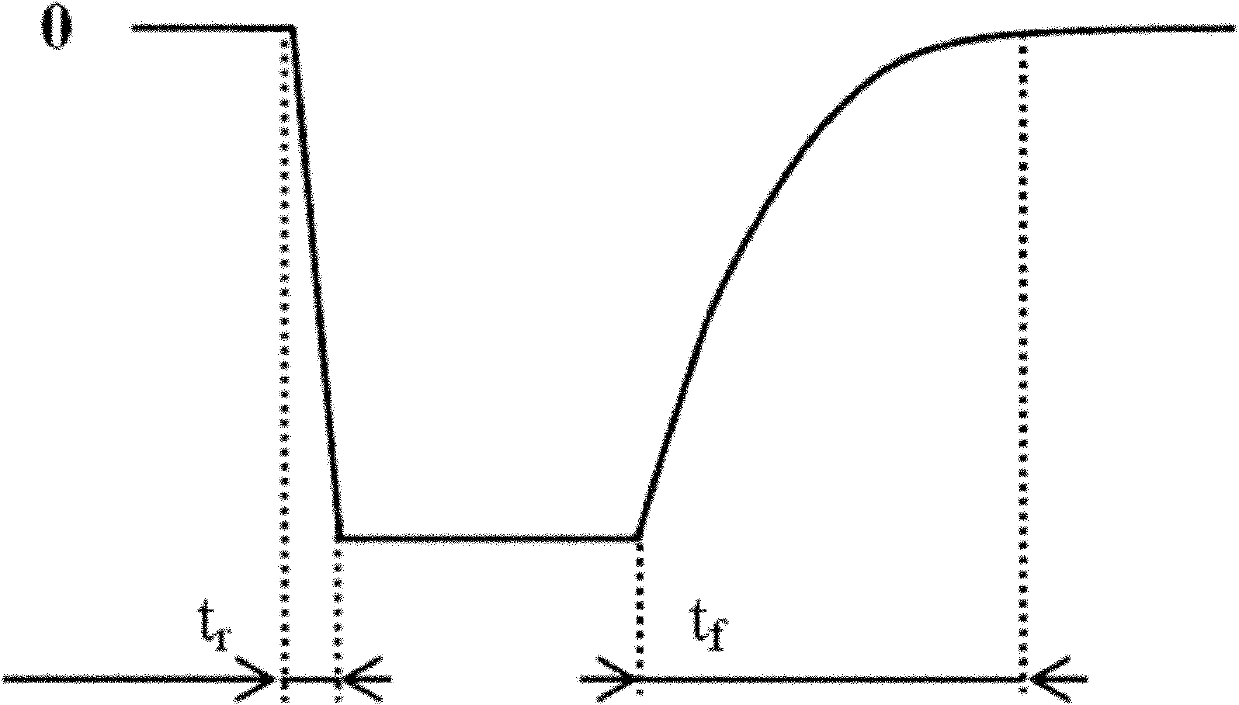

[0024] Specific implementation mode one: the following combination figure 1 , Figure 3 to Figure 5 Describe this embodiment, the high-voltage pulse modulator for plasma immersion ion implantation with steep falling edge and low power consumption described in this embodiment, which includes a DC high-voltage power supply 1, a charging current-limiting inductor 2, a charging IGBT series switch 3, and a current spike suppression inductor 4. Load current limiting resistor 5, vacuum tetrode 6, filament power supply 7, high voltage pulse capacitor 8, high voltage silicon stack 9, pull-down discharge current limiting resistor R p , pull-down IGBT series switch 10, parasitic capacitance C R , the second gate power supply 11, the driving original signal unit 12 of the charging switch, the charging synchronous isolation driving circuit 13, the pulse delay circuit 14, the electron tube driving circuit 15, the driving original signal unit 16 of the pull-down switch and the pull-down syn...

specific Embodiment approach 2

[0035] Specific implementation mode two: the following combination image 3 Describe this embodiment, the difference between this embodiment and Embodiment 1 is that it also includes a pull-down IGBT voltage equalizing circuit 18, and the pull-down IGBT voltage equalizing circuit 18 is connected in parallel between the emitter and the collector of the pull-down IGBT series switch 10 . Other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0036] Specific implementation mode three: the following combination image 3 Describe this embodiment, this embodiment is the further explanation to Embodiment 2, described pull-down synchronous isolation drive circuit 17 adopts pulse transformer, and the primary coil of pulse transformer connects the output end of driving original signal unit 16 of pull-down switch, and pulse transformer has multiple secondary coils;

[0037] The pull-down IGBT series switch 10 is composed of a plurality of IGBT low-voltage switches Z connected in series,

[0038] The pull-down IGBT voltage equalizing circuit 18 is composed of a plurality of resistance-capacitance voltage divider circuits, and each resistance-capacity voltage divider circuit is composed of a voltage-dividing resistor R and a voltage-dividing capacitor C in parallel,

[0039] Each secondary coil is connected in parallel between the collector and gate of an IGBT low-voltage switch Z, and a resistance-capacitance voltage divid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Voltage range | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com